Design, Simulation and Location Analysis of 100kw Power Plant by Bifacial Panels in Esfarayen, Iran

Mustafa Eydyany1, Afrooz Ghavami2*

1Khorasan Electric Generation Company, Mashhad, Iran

2Khorasan Institute of Higher Education, Mashhad, Iran

*Correspondence to: Afrooz Ghavami, Researcher, Khorasan Institute of Higher Education, No.77 Moalem 9137764483, Mashhad, Iran; Email: afroozghavami@gmail.com

Abstract

Objective: This study aims to investigate performance of the solar power plant by bifacial panels in two different places.

Methods: Power plant has been designed and simulated in two different geographical locations located in Esfarayen, North Khorasan, Iran. The site 1, with latitude of 37.07, almost in the central part of the city, and the site 2, located in shah jhan with latitude of 34.67. Pvsyst is used as simulation software to design and simulate photovoltaic systems.

Results: In site 1, the energy produced from the system is 189mWh per year and the payback time is 7.2 years. In site 2, the energy produced from the system is 223mWh per year and the payback time is 6.4 years.

Conclusion: It can be said that in the construction of a power plant, optimal positioning is one of the ways to increase efficiency.

Keywords: grid-connected solar system, bifacial panel, Pvsyst software, analysis and comparison

1 INTRODUCTION

In power plants that use conventional solar modules (mono-facial), the light reflected from the ground increases the internal temperature of the module and reduces its performance. Hence, the need for effective use of such reflected light can be clearly felt. At such a time, the Bifacial (dual) solar cell appears. Bifacial solar modules can absorb and convert solar radiation on both their front and back sides[1]. The history of bifacial solar cells dates back to 1960, when a Japanese researcher, H Mori, proposed a bifacial solar cell design and developed the prototype in 1966[2-4]. Compared to the conventional solar cell used in the current market, bifacial solar cells absorb more light on both sides due to the textured surface it has. Bifacial modules using these bifacial cells absorb more light by using transparent materials on both sides, allowing the effective use of light reflected from the earth's surface. Most photovoltaic (PV) cells are in fact bifacial in nature, but back contacts are not used and the back plate prevents light from passing through the cells from the back[5]. In recent years, researchers have shown a special interest in this technology. For this purpose, many studies have been done about it. This type of modules can be a way to improve the energy production density of a solar farm, which is the most important issue when available land is, limited (space limitation).

1.1 Bifacial Solar Cell Model

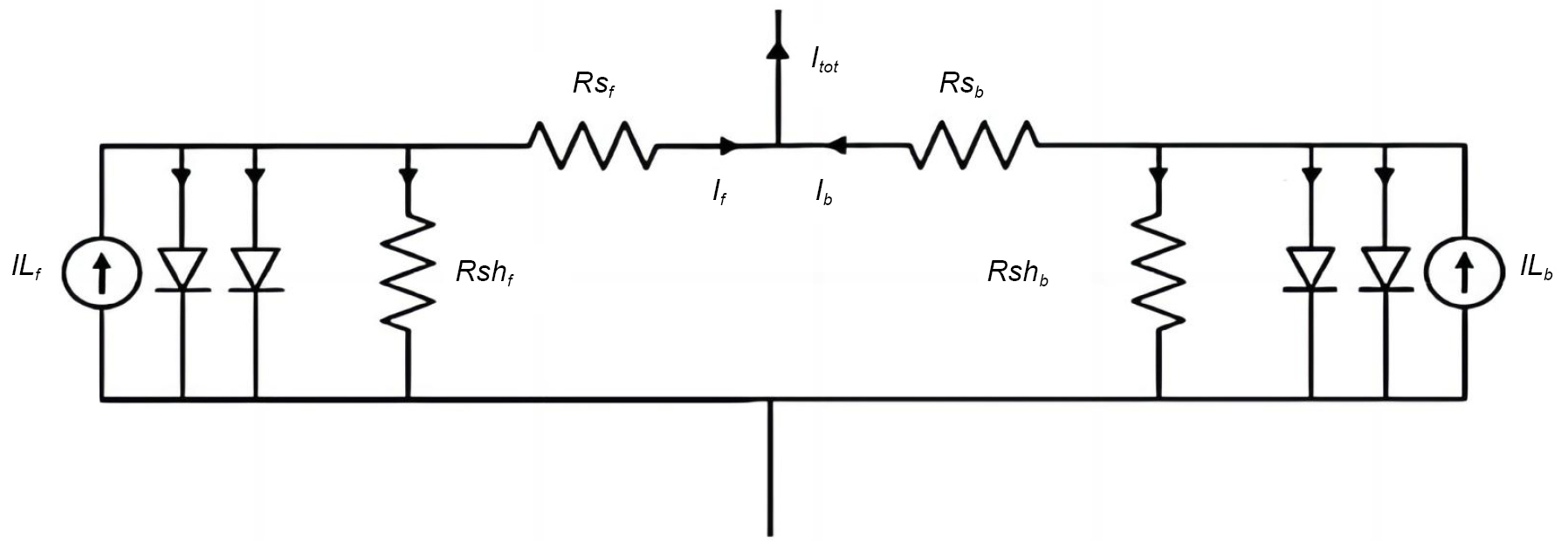

The equivalent circuit of a bifacial solar cell according to Figure 1 is modeled as two models of two diodes in parallel with two resistors in series and parallel. Subscript f corresponds to the front side of the cell, Subscript b to the back of the cell. Rsh is the shunt resistance: low shunt resistance produces light as an alternating current and causes power losses. Rs is the series resistance. The behavior of the rear PV is similar to that of the front, i.e. it follows the single diode model with the same parameters. So the back radiation is simply added to the front radiation, which is weighted by a two-dimensional factor when using the diode model[6-8].

|

Figure 1. Equivalent circuit of a bifacial solar cell.

1.2 Bifacial Cell Design

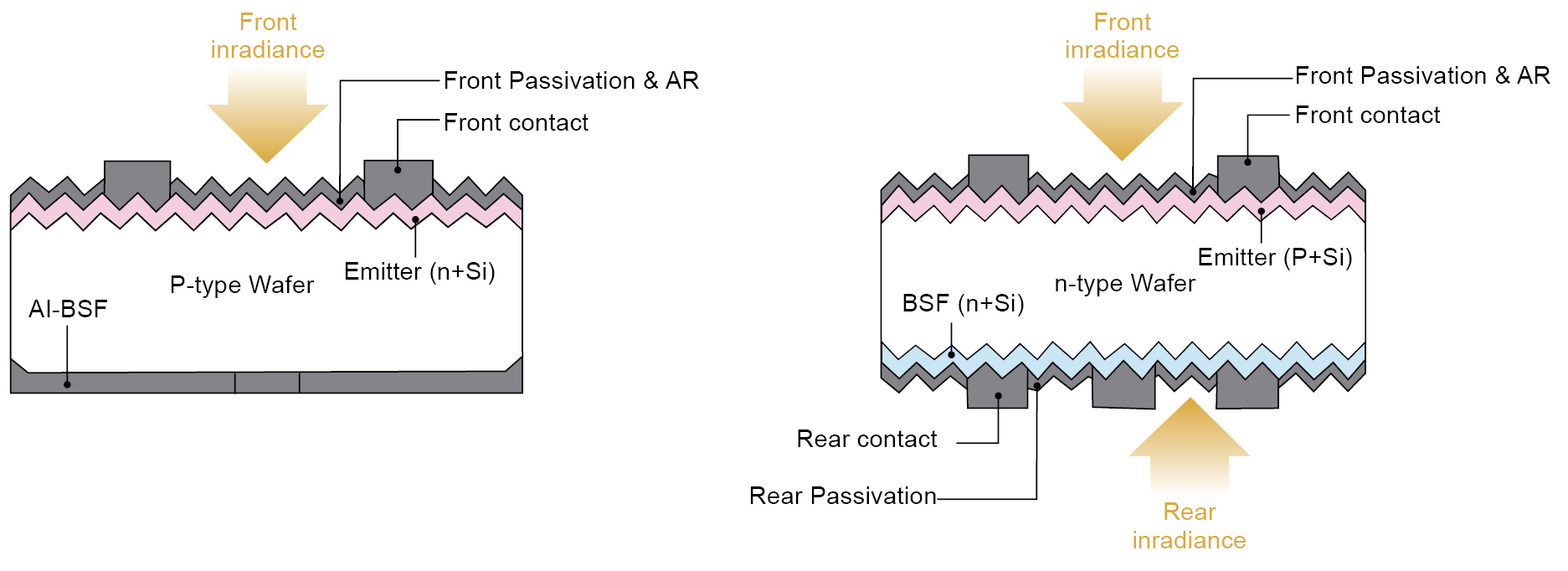

The back of a mono-facial solar cell is usually covered with aluminum paste. So no light can enter from this side. But a Bifacial cell is designed to collect light from the front and back of the solar cell, No aluminum paste should cover the back of the device and the back cover is made of a glass plate[9-11]. Figure 2 shows the basic structure of both mono-facial and bifacial cells.

|

Figure 2. Schematic comparison of mono-facial and bifacial solar cells.

1.3 Bifacial Panel Application

The previous generation solar panels were only able to absorb solar energy from one side and could not absorb the light coming from the ground to the other side, but in the new generation, because there are solar cells on both sides of these panels, these panels are able to absorb light from both sides of the panel and take solar energy from the light that hits the ground or other materials and is reflected to the other side of the panel and convert it into electricity. The bifacial panels are very thin and also its modules are placed between transparent layers so that light passes through it and hits the ground and is reflected back to the panel itself, which also increases the efficiency of this type of panel. By installing a bifacial panel in less space, more electricity can be generated. Bifacial solar panels are the best option for commercial and financial use, and these panels should be installed at a high altitude and at an angle to the ground so that light falls on the back of these panels and the solar energy behind the panel can be used and increase the efficiency of these panels. Also, bifacial solar panels can be very effective in some special residential homes as canopies as well as a power generating system, but for most homeowners who install panels on their roof, side panels are useful. They do not because light is not reflected behind it[12-15].

1.4 Characteristic of Bifacial Cells/Modules

The Bifacial PV module is considered as two models of two diodes in parallel, whose parameters are defined as follows:

Bifacial short-circuit current Equation (1):

|

X is the irradiance ratio, and RIsc the gain in short-circuit current relative to mono-facial front side only illumination, respectively defined as following Equation (2):

|

Gf is the irradiance on the front side of the solar cell, and Gr is the irradiance on the rear side of the solar cell.

Bifacial open-circuit voltage Equation (3):

|

|

Equation (4) Where pFF is the pseudo FF of the module considering no series resistance loss, which can be calculated using the front and rear I-V parameters measured under STC (standard test conditions: 1000W/m² and 25°C) as described in Equation (5):

|

The resulting bifacial power and bifacial efficiency are Equations (6) and (7):

|

|

|

1.5 Literature Review

Many studies have been done in the field of solar systems. For instance, previously, Al Mehadi et al.[18] Design and simulation of solar power plant with bifacial panels using PVSOL, Pvsyst and SAM software. The benefit of the bifacial module compared to the module Normal is calculated at 12.26%. Also, with the financial analysis, the total installation cost for the 30kW power plants has been stated as $84,759.74. Bhaduri et al.[19] studied the vertical bifacial module with the aim of reducing pollution. Shanmugam et al.[20] bifacial silicon wafer solar cells type n is investigated. Nussbaumer et al.[21] predicted the output of the bifacial system using a small test device by changing the tilt angle and stated that due to the low accuracy of traditional approaches to predict the output of the two-way system, using a small test device can be a suitable option. Mermoud and Wittmer[22] bifacial PV modules, simulations for horizontal axis trackers have been done by Pvsyst. Kabir and Matin Bhuiyan[23] system PV & Wind power use for sea water electrolysis and storage Hydrogen. To meet the peak load demand Gas Turbine Generator used to produce electricity using storage Hydrogen fuel for Bangladesh. Fazelpour et al.[24] the technical-economic feasibility of PV power plant 45kW grid-connected in Qeshm Island, Iran has been discussed by Pvsyst.

Eidiani et al.[25] designing a 100kW PV power plant by Pvsyst in two modes by mono-facial and bifacial PV modules. The simulation results of 100kW solar power plant for a mono-facial system show 153mWh per year. with an average performance ratio of 77.9% and for a bifacial system 170mWh per year. with an average performance ratio of 86.8%.

Panjwani et al.[26] Analysis of the efficiency of solar panels in the presence of solar concentrators at low and higher temperatures than the standard temperature has been investigated. Khan et al.[27] describes the application, training and validation by neural network for a 3kW power plant installed at North China Electric University in Beijing. Has stated that this network can accurately calculate and predict PV power. Khan et al.[28] designing an Algorithm by Neural Network to Minimize Errors Associated with Future PV Power Generation. Khan et al.[29] presenting a hybrid method based on the neural network model for a 3kW power plant in both clear weather and foggy weather. The authors claim that the proposed hybrid model can perform well when the weather is foggy. They have stated that other prediction models are less accurate in this field.

Eidiani and Ghavami[30] in the DIgSILENT Power Factory software, wind and solar generators and electric vehicles have been added to the distribution network and it has been shown that these three generators can be good complements to each other. The reliability and consistency of the transient stability in the network have been investigated in different faults. Eidiani et al.[31] improving Dynamic Response of Wind Turbine DFIG using Hybrid Particle Swarm Optimization and Genetic Algorithm. The results show that the proposed algorithm is well suited in terms of accuracy and quick response.

In this paper, a 100kW power plant in two different places in Esfarayen has been designed and investigated by bifacial modules with the same equipment. Then the economic evaluation has been compared and analyzed by calculating the costs and initial capital and annual profit and production.

2 MATERIALS AND METHODS

2.1 Site Assessment

This study was conducted for two different places located in Esfarayen, North Khorasan, Iran and the geographical location of both places is shown in Table 1.

Table 1. Geographical Location

|

Latitude |

Longitude |

Altitude |

Time Zone |

Site 1 |

37.07°N |

57.50°E |

1,237m |

UTC+3.5 |

Site 2 |

34.67°N |

69.05°E |

1,920m |

UTC+3.5 |

2.2 Meteorological Data

Table 2 shows the annual average of all data, including: temperature, the amount of radiation in different months of the year for the two studied locations and meteorological data was obtained from the Meteonorm 8.0 site.

Meteorological data can be selected from one of the databases available in Pvsyst. That these databases: Meteonorm 8.0, NASA-SSE, PVGIS TMY and NREL/NSRDB TMY.

Table 2. Annual Average of Meteorological Data

|

Site 1 |

Site 2 |

Horizontal global (kWh/m2) |

17,778.2 |

2,116.5 |

Horizontal diffuse (kWh/m2) |

625.6 |

484.8 |

Extraterrestrial (kWh/m2) |

2,998.3 |

3,077.6 |

Cleamess index (ration) |

0.593 |

0.688 |

Ambient Temper (℃) |

16.7 |

14.4 |

Wind velocity (m/s) |

2.5 |

2.8 |

2.3 Selection of Inverter and Module

In selecting modules and inverters, one of the factors to consider is which modules and inverters are available in the country and which modules the installers are familiar with.

For two sites, the same inverter and module with the specifications of Table 3 and Table 4 have been used.

Table 3. Selecting The Inverter Model

Model |

SMA_Tripower_20000TLEE_JP |

Nominal Ac power |

20kW |

Maximum efficiency |

98.50% |

Table 4. Modules Used in Two Geographical Locations

Model |

LGElectronics_LG400_N2T_A5 |

Technology |

Si-mono |

Nom.power |

400 |

Voc(25℃) |

50.5V |

Isc |

10.23A |

Nb cells |

72 |

Vmpp |

42.2v |

Efficiency |

21.63 |

Sizes |

40*1024*2064mm |

2.4 Orientation: How to Place the Panel and the Type of Structure

In this project, the unlimited sheds structure model has been used for the bifacial system.

Required parameters for bifacial simulation: pitch, width, height, ground albedo, mismatch factor for rear side contribution, module bifaciality factor, mismatch loss factor, height above ground, GCR.

These parameters can be briefly defined as follows:

Plane tilt: The angle of the panel and the structure with the ground level.

Azimuth: The direction of the panel, which is the same direction as south or west-east, and in the model of the structure in Iran, it is the same direction as south, and its value is equal to zero.

Albedo (For bifacial simulation): In fact, it is the surface albedo light that is scattered from the ground below the PV modules that is used to evaluate the back radiation of the PV modules.

Pitch: repeating distance between rows.

Bifaciality Factor: The ratio of rear efficiency to front efficiency. The bifacial coefficient is always less than 1.

GCR: It describes the ratio of the area of the module to the total area of the array. In other words, it describes the area ratio of the system used to collect sunlight[32].

Table 5 shows the specifications of the simulated bifacial system. I have experimentally considered these values for parameters according to studies and working with Pvsyst software.

Table 5. Features of The Bifacial Module

Height Above Ground |

3.0m |

|

Bifaciality factor |

0.75 |

|

Mismatch loss factor |

10% |

|

Ground albedo |

3.00 |

|

Coll. band width |

3.00 |

|

GCR |

50.0% |

|

Pitch |

6.00 |

|

Azimuth |

0.0 |

|

Plane tilt |

Site 1: 37.0̊ |

Site 2: 35.0̊ |

2.5 System Design

A nominal power of 100kW has been considered for the two geographical locations. Then Pvsyst selects the required number of inverters according to this nominal power and suggests a number of series and parallel modules to approach the desired power. In this case, 15 modules in series and 17 strings to produce a nominal power of 100kW. It is calculated. Pvsyst calculates the total number of modules required, which is approximately 255 modules with an available area of 539m2 (Table 6).

Table 6. Array Design

Number of Inverters |

5 |

Modules in series |

15 |

Number in strings |

17 |

Number in modules |

255 |

Area |

539m2 |

Array nom power (STC) |

102kWp |

Pnom ratio |

1.02 |

3 RESULTS AND DISCUSSION

3.1 Simulation and Results

Pvsyst provides a 6 to 11 page report to the designer. In this report, at the beginning, the introduction of the project and the settings given to the software and the justification plan prepared by the software, and the following pages provide the designer with the details of the project that he had calculated on a monthly basis, which include: The amount of production power, E_Array: The actual amount of power produced by the arrays, E_Grid: The power that can be produced annually, PR: performance ratio (annual yield), Loss diagram, environmental impact assessment and economic assessment, etc. Table 7 is a summary of The Pvsyst report is expressed as an annual average.

Table 7. Summary of Results

|

Site 2 |

Site 1 |

System production |

223mWh per year |

189mWh per year |

Specific production |

2,189kWh/kWp/yr |

1,853kWh/kWp/yr |

Performance ratio |

0.894 |

0.884 |

E_Array |

229.71mWh |

195.21mWh |

E_Grid |

223.25mWh |

188.98mWh |

3.2 Loss Diagram

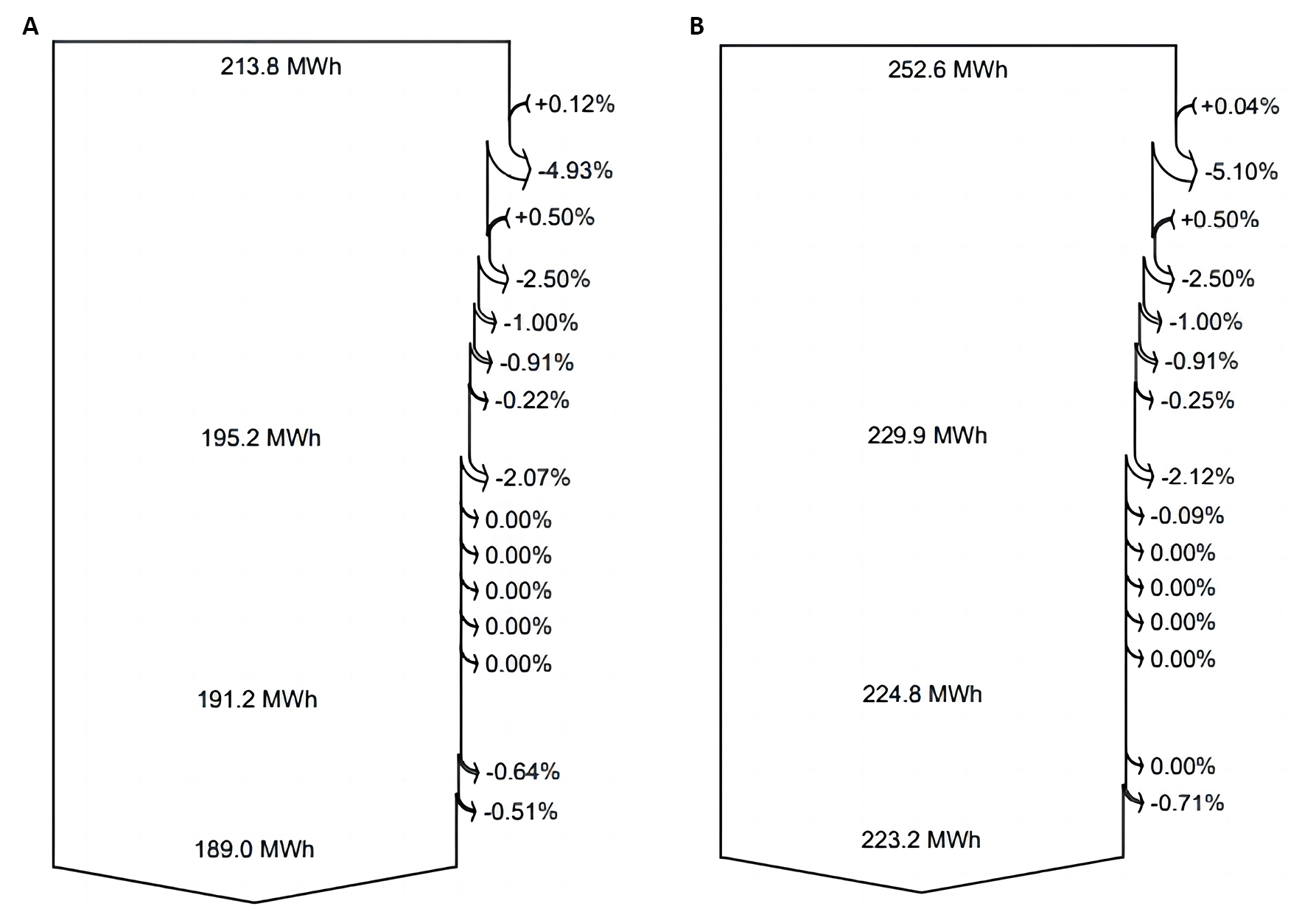

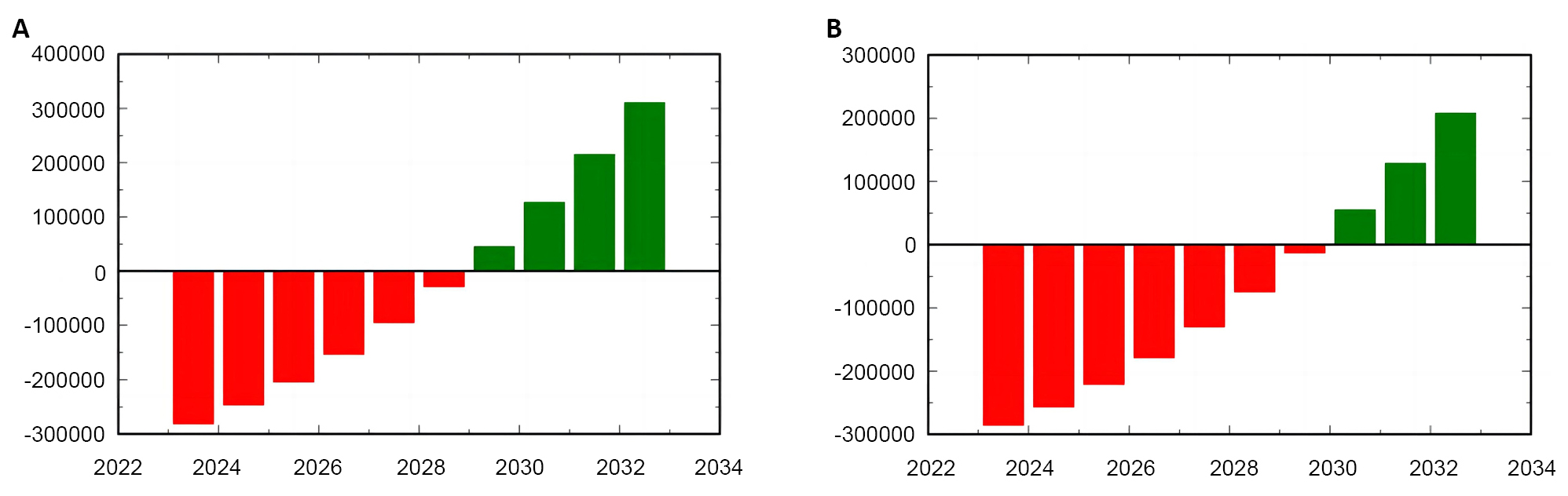

Figure 3A and B, show the total losses of the system from the time of receiving radiant energy per unit of horizon at the location of the power plant to the amount of energy injection into the network during one year for two geographical locations. It helps the designer to increase the efficiency of the power plant by eliminating these losses. In the site 1, it is 213.8mWh, which after deducting system losses has reached 189mWh when injected into the grid. In the site 2, according to the output reports of the Pvsyst software, the energy received by the panel set was 252.6mWh in the power plant complex, which reached 223.2mWh to the grid at the time of injection after deducting the system losses.

|

Figure 3. Loss diagram. A: Loss diagram for site 1; B: Loss diagram for site 2.

3.3 Environmental Impact Assessment

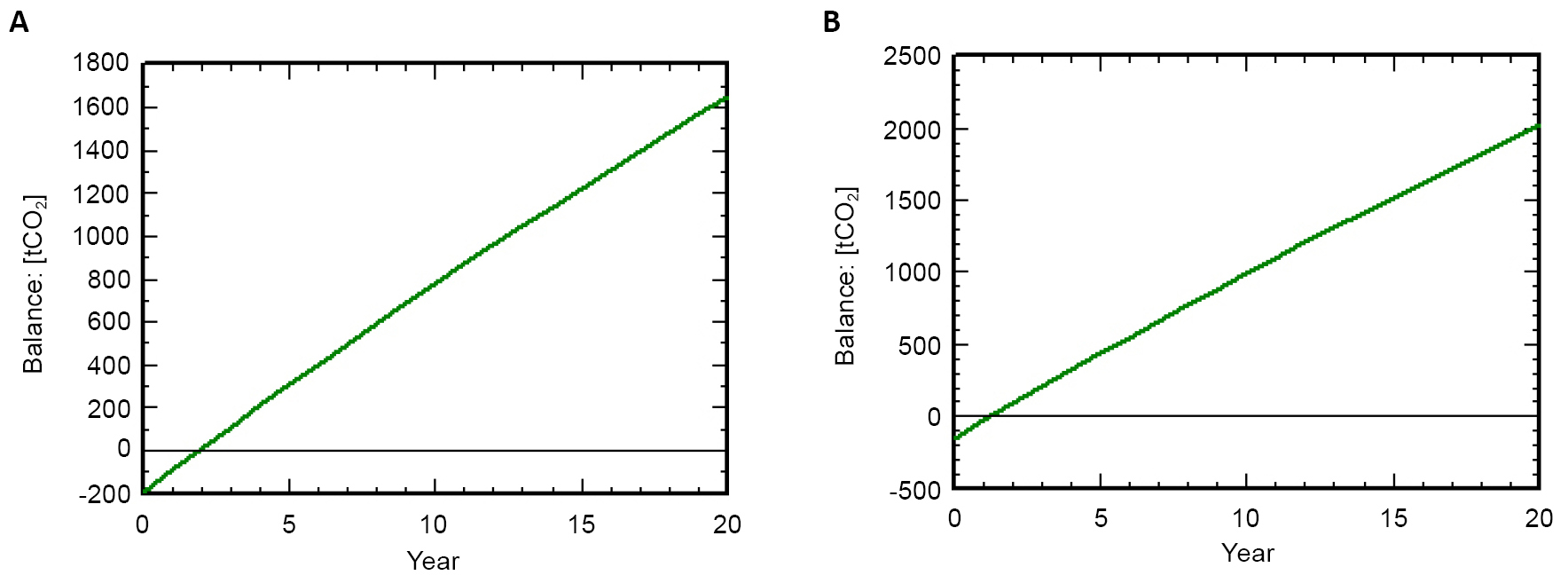

According to Pvsyst, according to the global standard, the first geographical location prevents the production of 1,649.482 tons of CO2 during 20 years. But the second location prevents the production of 2,020.340 tons of CO2 during 20 years is shown in Figure 4A and B.

|

Figure 4. Environmental impact assessment. A: CO2 emission balance for site 1; B: CO2 emission balance for site 2.

3.4 Economic Evaluation

All costs in this project are in thousands-Toman according to settings made in Pvsyst software. The cost of all the equipment has been considered in consultation with experienced people in this field and also by studying different sites example: manasazan company. As can be seen in Table 8, the total installation cost is 3,075,000 h-t and the price of solar panels is 2,040,000 h-t. The total price of the inverter is 475,000 h-t. Other costs, including structure, electrical panel, consultation and design, wire and cable and installation, are considered in total 615,000 h-t. Also, Table 9 shows the financial analysis. The simulation is carried out for 10 years. The price of each kWh of electricity is 12,740 IRR[33]. In this project, the simulation parameters according to Table 10 have been used.

Table 8. Cost of Equipment and Power Plant Installation

Description |

Price (h-t) |

The cost of the panels |

2,040,000 |

Inverter |

475,000 |

Other components: fasteners, wiring, combiner box, engineering, installation |

615,000 |

Repair and maintenance |

20,000 |

Total cost |

3,075,000 |

Table 9. Financial Evaluation of the Power Plant in the Two Studied Locations

Description |

Site 1 |

Site 2 |

Simulation time |

10 years |

10 years |

Production energy |

189mWh per year |

223mWh per year |

Payback time |

7.2 years |

6.4 years |

Energy sold to the grid |

5,671,392 |

6,699,872 |

Net profit |

5,152,218 |

6,180,699 |

Table 10. Parameters Considered in Economic Analysis

Annual Tariff Variation |

+30.0%/year |

Duration of tariff warranty |

10 year |

Inflation |

20.00%/year |

Production variation (aging) |

0.10%/year |

For the site 1: the energy produced from the system is 189mWh per year and the payback time is 7.2 years. The sale of electricity to the network is 5,671,392 (h-t) and also the profit of 10 years from the power plant is 51,52218 h-t (Table 8).

For the site 2: the energy produced from the system is 223mWh per year and the payback time is 6.4 years. The sale of electricity to the network is 6,699,872 (h-t) and also the profit of 10 years from the power plant is 6,180,699 h-t (Table 9).

3.5 Payback Period

According to Figure 5A and B, for the site 2: in 2028, Expenses and incomes have gone head to head, and from 2029, it has entered into profit, and this profit has reached the amount of 6,180,699 (h-t) in 2010. For the site 1: in 2029, Expenses and incomes have gone head to head, and from 2030, it has been profitable, and this profit has reached the amount of 5,152,218 (h-t) in 2010.

|

Figure 5. Payback period. A: Cumulative cash flow of the site 1; B: Cumulative cash flow of the site 2.

4 CONCLUSION

The following conclusions and recommendations were drawn from this work:

According to studies conducted in various sources and sites, with the advancement of technology, bifacial PV modules are expected to dominate the market in the near future, so research on this type of PV is necessary.

In site 2, 34.2 mWh of energy have been injected into the network more than in site 1 . It can be said that optimal location measurement is one of the ways to increase efficiency in power plant construction.

According to Pvsyst report, according to the graph provided to us, until the second year of the power plant, the CO2 produced by the production equipment compensates, and from the second year onwards, the power plant helps the environment to reduce CO2. In this project, the second geographical location has prevented the production of 370,858 more tons of CO2 during 20 years. This is very important and necessary in the future, like rejuvenating the population, governments should encourage and help the people to build a power plant even up to 5kW by installing it on the roof of the houses, so that everyone can help the environment in reducing CO2 in the atmosphere.

According to the price of mono-facial panels compared to bifacial panels, which is almost twice the price of bifacial panels and according to the mentioned advantages, If the price problem of bifacial panels is solved in the future, these panels will be a suitable option for solar power plants.

Acknowledgements

Not applicable.

Conflicts of Interest

The authors declared no conflict of interest.

Author Contribution

Eydyany M and Ghavami A contributed to the design, data collection, drafting manuscript and approved the final version.

Abbreviation List

PV, Photovoltaic

STC, Standard test conditions

References

[1] India. Waaree Energies Ltd. Accessed 2022. Available at:[Web]

[2] Mori H. Radiation energy transducing device. USA Pat Appl US142599A, 1966.

[3] USA. Office of Scientific and Technical Information (OSTI). Bifacial photovoltaic modules and systems: Experience and results from international research and pilot applications. Accessed 2022. Available at:[Web]

[4] Shishavan AA. Bifacial photovoltaic (PV) system performance modeling utilizing ray tracing [doctor’s thesis]. Iowa City, IA: The University of Iowa; 2019.

[5] Dupeyrat P, Lucas C, Lindsay A et al. Investigations on albedo dependency of bifacial PV yield: 29th European Photovoltaic Solar Energy Conference and Exhibition, Amsterdam, Netherlands, 22-26 September 2014.[DOI]

[6] Switzerland. PVsyst Software. Accessed 2022. Available at:[Web]

[7] Lucas C. Caractérisation électrique et modélisation de modules photovoltaïques à cellules bifaciales. 2014.

[8] Johnson J , Yoon D, Baghzouz Y. Modeling and analysis of a bifacial grid-connected photovoltaic system: 2012 IEEE Power and Energy Society General Meeting, San Diego, CA, 22-26 July 2012. San Diego, USA: IEEE; 2012.[DOI]

[9] Duran C. Bifacial Solar Cells: High Efficiency Design, Characterization, Modules and Application [doctor’s thesis]. Konstanz, German: University of Konstanz; 2012.

[10] USA. Solar Cells. Accessed 2022. Available at:[Web]

[11] India. Sterling and Wilson Private Limited. Accessed 2022. Available at:[Web]

[12] USA. Solar Power World. Accessed 2022. Available at:[Web]

[13] USA. SolarReviews. Accessed 2022. Available at:[Web]

[14] Iran. Sepenta Data Processing Company. Accessed 2022. Available at:[Web]

[15] Switzerland. PVsyst Forum. Accessed 2022. Available at:[Web]

[16] Singh JP, Walsh T, Aberle A. Characterization of bifacial solar cells and modules for bifacial illumination using standard indoor measurements. 2014.

[17] Singh JP, Aberle AG, Walsh TM. Electrical characterization method for bifacial photovoltaic modules. Sol Energy Mater Sol Cells, 2014; 127: 136-142.[DOI]

[18] Mehadi AA, Nishat MM, Faisal F et al. Design, Simulation and Feasibility Analysis of Bifacial Solar PV System in Marine Drive Road, Cox’s Bazar: 2021 International Conference on Science & Contemporary Technologies (ICSCT), Dhaka, Bangladesh, 05-07 August 2021. Dhaka, Bangladesh: IEEE; 2021.[DOI]

[19] Bhaduri S, Kottantharayil A. Mitigation of soiling by vertical mounting of bifacial modules. IEEE J Photovolt, 2019; 9: 240-244.[DOI]

[20] Shanmugam V, Chen N, Yan X et al. Impact of the manufacturing process on the reverse-bias characteristics of high-efficiency n-type bifacial silicon wafer solar cells. Sol Energy Mater Sol Cells, 2019; 191: 117-122.[DOI]

[21] Nussbaumer H, Klenk M, Morf M et al. Energy yield prediction of a bifacial PV system with a miniaturized test array. Sol Energy, 2019; 179: 316-325.[DOI]

[22] Mermoud A, Wittmer B. Yield simulations for horizontal axis trackers with bifacial PV modules in PVsyst: 35th European Photovoltaic Solar Energy Conference, Brussels, Belgium, 24-28 September 2018.[DOI]

[23] Kabir KM, Matin Bhuiyan MA. Design and simulation of hydrogen based hybrid green power system using sea water for Cox’s Bazar. Cogent Eng, 2017; 4: 1347029.[DOI]

[24] Fazelpour F, Shariatzadeh M, Soltani N. Techno-economic feasibility of grid-connected photovoltaic power plant in Qeshm Island, Iran: 2016 IEEE 16th International Conference on Environment and Electrical Engineering (EEEIC), Florence, Italy, 07-10 June 2016. New York, USA: IEEE; 2016.[DOI]

[25] Eidiani M, Zeynal H, Ghavami A et al. Comparative Analysis of Mono-Facial and Bifacial Photovoltaic Modules for Practical Grid-Connected Solar Power Plant Using Pvsyst: IEEE International Conference on Power and Energy (PECon2022), Langkawi, Malaysia, 05-06 December 2022.

[26] Panjwani MK, Meicheng L, Khan D et al. Effect of solar concentrators on the efficiency of solar panels: 2018 International Conference on Computing, Mathematics and Engineering Technologies (iCoMET), Sukkur, Pakistan, 03-04 March 2018. New York, USA: IEEE; 2018.[DOI]

[27] Khan I, Zhu H, Khan D et al. Photovoltaic Power prediction by Cascade forward artificial neural network: 2017 international conference on information and communication technologies (ICICT), Karachi, Pakistan, 30-31 December 2017. New York, USA: IEEE; 2018.[DOI]

[28] Khan I, Zhu H, Yao J et al. Photovoltaic power forecasting based on Elman Neural Network software engineering method: 2017 8th IEEE international conference on software engineering and service science (ICSESS), Beijing, China, 24-26 November 2017. New York, USA: IEEE; 2018.[DOI]

[29] Khan I, Zhu H, Yao J et al. Hybrid power forecasting model for photovoltaic plants based on neural network with air quality index. Int J Photoenergy, 2017; 2017: 6938713.[DOI]

[30] Eidiani M, Ghavami A. New network design for simultaneous use of electric vehicles, photovoltaic generators, wind farms and energy storage: 2022 9th Iranian Conference on Renewable Energy & Distributed Generation (ICREDG), Mashhad, Iran, 23-24 February 2022. New York, USA: IEEE; 2022.[DOI]

[31] Eidiani M, Shahdehi NA, Zeynal H. Improving Dynamic Response of Wind Turbine Driven DFIG with Novel Approach: 2011 IEEE Student Conference on Research and Development, Cyberjaya, Malaysia, 19-20 December 2011. New York, USA: IEEE; 2012.[DOI]

[32] Switzerland. Bifacial Systems. Accessed 2022. Available at:[Web]

[33] Iran. SATBA. Accessed 2022. Available at:[Web]

Copyright © 2023 The Author(s). This open-access article is licensed under a Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, sharing, adaptation, distribution, and reproduction in any medium, provided the original work is properly cited.

Copyright ©

Copyright ©