Comprehensive Review on Lipid-based Biomasses as Biodiesel Raw Materials from Ghana

Mohammed Takase1*, Rogers Kipkoech2, Francis Kamau Irungu3, Joy Kibet3, Faith Mugah3

2National Environment Management Authority (NEMA), Nairobi, Kenya

3Department of Spatial and Environmental Planning, School of Architecture and the Built Environment, Kenyatta University, Kenya

*Correspondence to: Mohammed Takase, PhD, Department of Environmental Science, School of Biological Sciences, College of Agriculture and Natural Sciences, University of Cape Coast, Cape Coast CC000-CC525, Ghana; Email: mohammed.takase@ucc.edu.gh

Abstract

Ghana is a country rich in natural resources, including biodiversity and large water bodies, but it is also plagued by food and energy shortages. Fuel prices are also increasing. Biodiesel made from lipids will attract increasing attention as researchers and experts look for a solution. However, the obvious cheapest option of edible feedstock will be insufficient to meet rising energy and food demand, necessitating the need for a guaranteed feedstock. As a result, this research was conducted to identify lipid-based biomass feedstocks that would be ideal for biodiesel production in Ghana. This research seeks to give current information on the biofuel feedstock currently existing (mostly biodiesel) synthesis from lipid-based biomasses in Ghana. Edible plant oils were the first generation of lipid-based feedstocks, whereas alternative types of feedstocks were identified and reported as the second generation. Non-edible oils, like Jatropha oil, Neem oil, Karanja oil, Nagchampa oil, Calophyllum inophyllum oil, Mahua indica oil, Rubber seed oil, and other non-edible feedstocks are used to make second-generation biodiesels. Vegetable oil waste, industrial wastes and by-products, animal fats, and lipid-derived from microorganisms and insects are also among the 2nd generation feedstocks discussed in this paper. The advantages of 2nd generation feedstocks are the low-cost, high-yielding, and the fact that they do not economically or ethically compete with edible oils (food crops). Nevertheless, all 2nd generation feedstocks are often free fatty acids and having high moisture, which have a significant detrimental impact on the conventional biodiesel synthesis process. As a result, this article contains basic information on processing procedures that can handle 2nd generation feedstocks.

Keywords: biodiesel, non edible oil, edible oil, Ghana

The expanding global population, modernization, economic development, and industrialization are primary elements driving up energy demand[1]. The global population is expected to rise to 8.8 billion people by the year 2035 leading to increased demands for energy[2]. Fossil fuels, coal, petroleum and methane are some of the non-renewable sources of energy. These are the main sources of energy now, and scarcity is on the way due to increased use[3]. Biofuels are superior alternatives to fossil energy like coal, oil, and natural gas, and are gaining popularity due to benefits such as environmental friendliness, renewability, abundance, biodegradability, and sustainability, among others[4]. According to Ibrahim et al.[5], biodiesel has recently gotten a lot of attention because of the fossils-based petroleum fuel which are getting depleted and increasing environmental concerns. These factors have established a solid foundation for biodiesel production to continue rising with the support of a variety of policies around the world, despite its recent deterioration in competitiveness with crude petroleum oil. Biodiesel is produce by a combination of mono-alkyl esters made through fatty acid esters of waste oils, edible, and non-edible oils[6]. Biodiesel can be made from various feedstocks, including algal oils, vegetable oils, animal fats, waste oils and microbial oils[7-9]. The processes for producing biodiesel also include pyrolysis, transesterification, and the supercritical fluid method, among others[9]. In compression ignition (CI) engines, biodiesel can either be mix with diesel or applied directly as alternative source of fuel engine[10]. The characteristics of biodiesel include sustainability, oxygenated, free from sulfur, and biodegradability renewable energy source. According to Dwivedi et al.[11], utilizing biodiesel as a fuel requires no modifications in diesel engines. In comparison to diesel fuel, biodiesel emits fewer regulated and unregulated emissions[12].

In 2035, fossil fuels will continue to be the dominating energy source, accounting up to three-quarters and more of global energy, down 10% from 2015[13-15]. However, according to Noor et al.[16], renewable energy, to the contrary, is predicted to develop rapidly, with consumption rising from 439 million tons of oil equivalent and 1715 Mtoe in 2015 and by 2035 respectively. The increase in the trend could be owing to a scarcity of coal supplies (0.2% decline per year) and future environmental rules enforced by most countries. Shares of renewable energy which include biofuels that are increasingly growing from 3% in 2015 to 10% in 2035 is projected to outdo energy from the nuclear in the early 2020s and also hydroelectricity with in the first years of 2030s. Renewable energy is expected to grow at a rate 7.1% annually for the next twenty years.

Biodiesel is used as an substitute fuel for a variety of reasons, including reduced emissions of greenhouse gas, less impact on the global environment, renewable and sustainable energy solutions, and a more viable alternate fuel supply to fulfil current increasing energy demand[17]. Using biodiesel increases the emission of carbon dioxide, particulate matter, unburned hydrogens and carbon monoxide[18]. Biodiesel has several advantages over diesel fuel, including environmental friendliness, renewability, non-toxicity, biodegradability and high flash point[19]. Biodiesel has qualities like petroleum diesel and emits fewer pollutants, making it a viable substitute to diesel fuel in the transportation sector. An increase in biodiesel use could help to minimize pollution and mobile carcinogens.

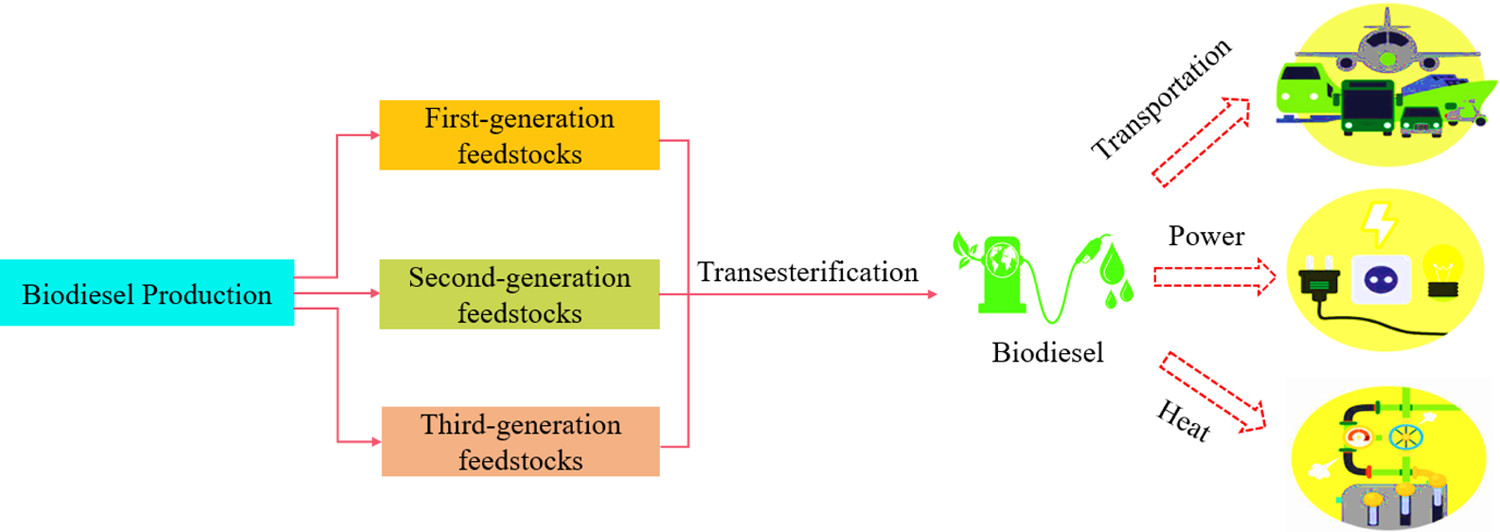

This review seeks to highlight by providing data on available lipid-based biomasses that can be used for biodiesel production in Ghana. It is made up of lipid-based biomasses from oil plants which include edible plant oil and non-edible plant oil. Edible oil plants are obtained from crops that are potential first-generation feedstock for the production of biofuel and these are maize, sugarcane, sweet sorghum, cassava for, oil palm, sunflower, soybean, and coconut. Non-edible oils are plants oil considered as second-generation feedstock feedstocks which include seed oil from jatropha, neem, nagchampa oil, calophyllum, and karanja. The review further highlights lipid-based biomasses from wastes and by-products and lipid-based biomasses from microorganisms which are categorised as third generation feedstocks for producing biodiesel. Lipid-based biomasses from wastes and by-products include; waste oils, such as waste cooking oil, and animal tallow oil while lipid-based biomasses from microorganisms are; microalgae, fungi, yeasts and bacteria. The review finally concludes and gives recommendations and biofuels production prospects for second-generation lipid-based biomasses in Ghana (Figure 1).

|

Figure 1. Classification of feed stocks for biodiesel productions and uses of biodiesel. Source: https://pubs.acs.org/doi/full/10.1021/acsomega.1c02402

2 LIPID-BASED BIOMASSES FROM OIL PLANTS

Biodiesel is categorized as the first and second generation based on the feedstock being utilized[20]. First generation refers to that biodiesel made from edible feedstocks such as soybean, coconut, canola, palm oil, peanut, and others, which are sources of food to human beings, on the contrary, second-generation biodiesel, is typically made from non-edible feedstocks such as waste oil, jatropha, and distilled palm fatty acid[21]. The crops that are potential feedstock for the production of biofuel in Ghana are maize, sugarcane, sweet sorghum, cassava for producing ethanol, oil palm, sunflower, soybean, and coconut for the production of biodiesel (Table 1).

Table 1. Fatty Acid Methyl Ester Composition of Several Biodiesels Obtained from Edible Oils[22,23]

Oil |

Palmitic (C16:0) |

Stearic (C18:0) |

Oleic (C18:1) |

Linoleic (C18:2) |

Linolenic (C18:3) |

Soybean |

12.13 |

3.49 |

23.41 |

54.18 |

6.50 |

Peanut |

8.75 |

2.14 |

60.21 |

21.28 |

0.54 |

Sunflower |

7.95 |

1.91 |

12.59 |

77.54 |

- |

Cottonseed |

26.23 |

1.30 |

13.30 |

59.13 |

- |

Coconut |

8.0-11.0 |

1.0-3.0 |

5.0-8.0 |

0-1.0 |

- |

Palm |

39.83 |

5.33 |

41.90 |

11.46 |

0.15 |

Allanblackia seed oil |

1.39 |

49.87 |

44.87 |

1.18 |

- |

Asiato (P. insignis) |

56.58±0.17 |

4.72±0.01 |

9.33±0.09 |

6.58±0.11 |

nd |

Tiger nut (C. esculentum) |

16.32±0.06 |

5.33± 0.04 |

65.55±0.08 |

12.13±0.12 |

nd |

Notes: nd, not determined.

2.1 Edible Oil Plants in Ghana

Edible oils are increasingly becoming recognized as food, biofuel, and health-promoting compounds like nutraceuticals, as well as industrial polymers feedstock and several other products from industrial[24]. As a result, worldwide demand for edible oils is likely to continue to rise year after year, putting downward pressure on oil prices. According to the literature, edible oils account for over 95% of global biodiesel production[25]. However, as a result of the food vs. fuel dilemma, edible oil consumption is increasing. Soon, it is predicted that there will be main environmental difficulties, such as serious loss of vital resources in the soil, deforestation, and abuse of limited agricultural land. Saturated oils, such as palm kernel and coconut and unsaturated oils, such as soybean, sunflower and canola oils are two types of lipid-based biomass generated from edible oil plants, especially cooking oils. Lauric acid (C12:0), palmitic acid (C16:0), myristic acid (C14:0), oleic acid (C18:1), stearic acid (C18:0), linolenic acid, and linoleic acid are the most common fatty acids (FAs) found in edible oils and fat (C18:3). The code (CX:Y) relates to the fatty acid molecule's number of carbon atoms (X) and C14C double bonds (Y). Because edible oils are readily available, they are the first generation of biofuel produced from biomass from lipids[26].

2.1.1 Tiger Nut (C. esculentum)

In West Africa regions, particularly in Ghana tiger nut, C. esculentum, is a popular snack. In Ghana, tiger nuts are consumed while it is raw as a snack or as milk after crushing to produce the milk which is white in colour which is used to make a delectable porridge. Mensah and Obeng[27] carried out on a modest scale, on the oil extractions from the nut using conventional methods for food purposes. C. esculentum, often known as tiger nut, is a Cyperaceae plant whose cultivation was done in ancient time in Egypt[28]. Tiger nut is currently commonly grown as wild grass which is like a plant throughout West Africa, including Ghana. Tiger nut is common to other places globally, particularly in Spain's Valencia region, where it is referred as “chufa” and the nut's oil whose production is currently commercial and is sold at the European market (Tiger nuts Traders, 1997-2010). According to Nina et al.[28] oleic (69.25%), palmitic (15.19%), linoleic (8.37%), and stearic (5.07%) acids were the primary FAs in tiger nut tuber oil.

2.1.2 Palm Oil or Palm Fruit (Elaeis guineensis)

In comparison to other oilseeds, palm oil or palm fruit (Elaeis guineensis) is the most promising biodiesel feedstock[29]. Palm oil has a higher yield and requires less fertilizer, water, and pesticides to grow[30]. Production of palm oil uses little sunshine for a unit of oil to be created in terms of energy balance because it generates more oil per hectare. However, because of the complexity of labour plantation management and fruit harvesting, palm oil yield per man per day is not as competitive as other oilseeds. Palm oil and refined palm oil have increases popularity vegetable oils on the market today[31]. Palm oil is known for its nutrient content, which makes it excellent for daily cooking, according to Imoisi et al[32]. The fleshy mesocarp, the inner wall of the fruit, is also essential for palm oil manufacturing. The oil palm tree (Elaeis guineensis) is mostly grown in Central Africa and areas of West Africa in Africa[33]. Nigeria is the world's top producer of palm oil, with a 3%, followed by Côte d'Ivoire and the Democratic Republic of Congo, each with a 0.5%[34]. The Ashanti, Western, and Eastern regions of Ghana have over 320,000 hectares of oil palm plantations, which are largely in the rainforest and deciduous zones[35]. Oil palm farming is done on a variety of scales, including medium-to large-scale plantations and smallholder farms.

The plant P. insignis of the Bombacaceae family is known as Asiato among the inhabitants of Ghana's Volta Region. P. insignis, also known as "wild chestnut", is one of just two edible Pachira species (there are 24 in the genus)[28]. The seeds of the asiato are mashed into a paste and used as a thickening in stews and sauces in Ghana, much like groundnut paste is used in many regions of West Africa. Even though asiato seeds are high in oil, they are exclusively harvested for cooking in a few rural villages. However, literature is scarce on the specific composition of the major components, such as triacylglycerols (TAGs), and minor components, such as vitamin E and phytosterols compounds, in the seed oils of asiato plants produced in the West African region.

Globally, coconut oil account for approximately 20% of the vegetable oil produced and coconut is broadly harvested in tropical coastal areas. Coconut oil is extracted from the copra, the dried flesh of the nut. Coconut oil remains solid at a relatively high temperature than most other vegetable oils. Coconut oil in liquid form is capable of producing 50% motor fuel as diesel fuel since it burns without much emission in diesel engines. The main drawback of using coconut oil in engines is that it starts solidifying at a temperature below 22℃ and by 14℃ it does not flow at all. Ghana's coconut farms occupy over 30,000 ha and produce roughly 5,000 nuts per ha on average[36]. However, the Cape Saint Paul Wilt Illness, a devastating yellowing disease, has damaged around 4,000 ha of these plantations, mostly in the coastal zone[28]. A Coconut Sector Development Project was implemented by the government between 1990 and 2005, resulting in the rehabilitation of roughly 800 acres of coconut crops.

2.1.5 Sunflower

Sunflower is gaining popularity as a possible biofuel feed stock in the country[37]. Sunflower seed farming is primarily done on smallholder farms. Sunflower oil is well recognized around the world, but due to its unique growth circumstances, it can only be grown in a small area and cannot compete with other well-known oil seeds in the area[38]. Sunflower oil usage is declining in Ghana, probably due to the availability of alternative edible oils at a lower cost. The primary fatty acid in sunflower oil is linoleic acid (62.69%), followed by oleic acid (25.92%) (ranged 22.83-31 to 24%). There is a moderate quantity of total saturated fatty acid (11.39%), with palmitic (6.43%) and stearic (3.69%) acid being the major sources[39]. Sunflower oil has a high level of oleic and linoleic acid, accounting for 85 to 90% of total fatty acid, making it unique among edible oils. Sunflower oil, like groundnut and coconut oil, is devoid of linolenic acid[40]. In Ghana, around 230 ha of sunflower farms were recently constructed under a project sponsored jointly by the United Nations Development Programme and the Global Environment Facility/Small Grant Project.

Soybean is the most widely grown oilseed crop on the planet. Soybean oil is a popular biodiesel production source in Ghana. Sunflower oil and soybean oil have the same iodine content[41,42]. The Soyabean tree grows to a height of 0.5 to 1.2m. Soybean has a lower yield of oil per hectare than other crops[9]. Soybeans have the potential to fix nitrogen, which is why they can be grown in both temperate and tropical climates[43]. Soybean also replenishes nitrogen in the soil. Soybean requires less fertilizer because it generates a positive fossil energy balance. Soyabean oil has physical qualities such as density, heating value and viscosity, of 916kg/m3 (at 15℃), 39.6MJ/kg and 31.83mm2/s (at 40°C), respectively, according to Singh et al., 2019[44]. Linoleic acid (50-60%), palmitic acid (6-10%), oleic acid (20-30%), and linolenic acid (5-11%) are all found in soyabean oil[41]. Production of soybean amounts to 50,000 tonnes in Ghana annually but only 15,000 tonnes are being consumed locally. Cultivation of soybean is intense mostly in the Northern, Upper East, and Upper regions.

The tallow tree (Allanblackia floribunda) is a dicotyledonous woody plant of the Guttiferae family and genus Allanblackia that is underused[22]. It is an evergreen shrub that grows well in wet areas, particularly in rainforests, and yields large brown fruits. The seeds that carry the Allanblackia oil are found inside those fruits[45]. Allanblackia seed oil is a vegetable lipid that is solid and stable at room temperature (28-20°C), has a slip melting point above 350°C, and stays solid until 410°C[45]. Its high stearin concentration of around 49% makes it an excellent source of hard stock for blending and modification. The seeds of the vegetable tallow tree (Allanblackia floribunda) are used to make Allanblackia seed oil[46]. The trees can be found throughout Africa, primarily in Cameroon, Sierra Leone, and Gabon, as well as Congo Brazzaville, Ghana, and Uganda. It grows in the Central, Western, Ashanti, and Eastern parts of Ghana[17]. The oil derived from the seeds has traditionally been used for subsistence cooking, medication preparation, and soap production. The oil can now be used to make spreads (margarine), soap, and cosmetics. Several characteristics of this oil, such as its high melting point and higher food value, make it superior to alternatives such as palm oil[22].

2.2 Non-edible Oil Plants in Ghana

Non-edible feedstocks including oil from Jatropha seeds, Neem oil, Nagchampa oil, Calophyllum inophyllum oil, Karanja oil, Mahua indica oil, Rubber seed oil, and other non-edible feedstocks are used in generating second-generation biodiesels (Table 2)[9,48,49]. The main benefits of using feedstocks that second-generation to produce biodiesel is the eliminating of necessity to replant food plant and also eliminate the need for extensive land for agriculture[9]. Yields of non-edible plants diminish for primary plants which include Jatropha oil, Jojoba oil, and Karanja oil, which is one of the disadvantages of feedstock that are of second-generation in nature[49]. Growing of feedstocks that are second generation can be carried out on peripheral land. That is the reason it is compelled to grow crops that are not edible on farmland; it has a direct impact on society's economics and food production. To address the socio-economic challenges related with the issue of non-edible oil, researchers are focusing on developing alternative options that are both economically practical and easily available[50]. A disadvantage of second-generation biodiesel is the demand for more alcohol[51]. Although the non-edible and edible oil oils have nearly identical fatty acid, saturated fat, and unsaturated fat compositions, the edible oil contains essential nutrients and antioxidants. Non-edible oil derived from Jatropha, rubber seed, sea mango, and candlenut, on the other hand, cannot be consumed by human beings due to hazardous chemicals included in the oil[52]. Purgative and curcas are found in Jatropha seed oil, for example[11]. Cyanogenic glucoside is found in rubber seed oil[53]. As a result, oil derived from non-edible crops can be used as an alternative feedstock for biodiesel synthesis, overcoming the food versus fuel dilemma by utilizing non-edible oils for biodiesel production (Table 3)[53].

Table 2. The Lipid Content and Productivity of Selected Non-edible Oil Plants[6,41,47]

Oilseed |

Lipid Content in Dry Biomass (w/w) |

Oilproductivity (kg/ha/yr) % |

Moringa tree (Moringa oleifera) |

30-40 |

4680 |

Rubber seed (Hevea brasiliensis) |

40-60 |

50 |

Allanblackia parvifora |

49 |

64.2-68 |

Neem tree (Azadirachta indica) |

25-45 |

2670 |

Jatropha tree (Jatropha curcas) |

40-60 |

2500 |

Cottonseed (Gossypium) |

17-23 |

649 |

Table 3. Fatty Acid Profiles of Selected Non-edible Oil Plants[6,17,45,52]

|

Fatty Acid |

Seed |

|

|||||

Moringa Tree (Moringa oleifera) |

Rubber Seed (Hevea brasiliensis) |

Neem Tree (Azadirachta indica) |

Jatropha Tree (Jatropha curcas) |

Cottonseed (Gossypium) |

Allanblackia parvifora |

|||

Palmitic (C16:0) |

7.6 |

10.2 |

14.9 |

14.6 |

24.15 |

2.5 |

||

Stearic (C18:0) |

5.5 |

8.7 |

20.6 |

7.6 |

2.90 |

51.6-52.3 |

||

Oleic (C18:1) |

66.6 |

24.6 |

43.9 |

44.6 |

19.32 |

43.9-44.8 |

||

Linoleic (C18:2) |

8.1 |

39.6[17] |

17.9 |

31.9 |

50.72 |

- |

||

Linolenic (C18:3) |

8.2 |

16.3 |

0.4 |

0.3 |

1.45 |

- |

||

2.2.1 Cottonseed (Gossypium)

According to Tabashnik and Carrière[54], Europe, China, and the United States are the biggest producers of cotton. Cotton plants, however, are grown in various African countries, including Ghana[55]. Cottonseed oil is produced from Gossypium herbaceum and Gossypium hirsutum, two primary kinds of Cotton plants. Cotton plants has a potential to grow up to 1.2m tall[56]. Non-glyceride components in this oil include sterols, gossypol, carbohydrates, phospholipids, resins and pigments that are connected[56]. This oil has a density of 917-933kg/m3 (at 15 degrees Celsius). Also, Cotton Seed oil has a viscosity of 34.79mm2/s (at 40°C) and a heating value of 39.5MJ/kg[56]. Cotton seeds contain oil in the range of 17-25%. The oil contains FAs such as oleic acid, which is 19.2 to 23.26%, palmitic acid, which is 11.67-20.1%, and linoleic acid, which is 55.2-55.5%[11].

2.2.2 Jatropha (Jatropha curcas)

Jatropha is a semi-arid, marginally farmed oilseed plant. Scrub can be gathered twice a year, is little noticed by cattle, and can last for 30-50 years[57]. After one year of planting, the plant produces seeds, and after five years of planting, the plant's productivity is at its peak (Singh et al., 2013[58]). The plant Jatropha belongs to the Euphorbiaceae family and can reach a maximum height of 5-7m[59]. Jatropha can thrive in a range of climates, including stifling temperatures, minimal rainfall, excessive precipitation, and cold. Jatropha is produced in lands that marginal as well as wastelands where there is no chance of competing land use with food production[58]. The amount of oil in jatropha depends on the species, the climate, and, most importantly, the altitude at which it is grown[60]. The plant's many sections offer therapeutic properties. The Jatropha plant can be found in Paraguay, India, Argentina, Brazil, the United States, Bolivia, Africa, and Mexico[6,9]. Jatropha has recently been identified as the most possible and promising source of oil to produce biodiesel in Asia, Europe, and Africa[61]. In addition to provision of oil for substituting diesel, the growth of trees in Ghana effectively reduces CO2 levels in the environment. Oil from jatropha is one of the crucial sources of oil for producing biodiesel. The oil content of Jatropha seeds ranges from 20 to 60%. Jatropha oil has a heating value of 38.96MJ/kg, a density of 916kg/m3 (at 15°C), and a viscosity of 37.28mm2/s (at 40°C)[44]. Jatropha has largely unsaturated components including oleic (34.3-44.7%) and linoleic acid (31.4-43.2%), as well as some saturated components which include palmitic acid (13.6-15.1%) and stearic acid (7.1-7.4%)[62].

2.2.3 Neem (Azadirachta indica)

According to Singh et al.[9] Bangladesh, India, Australia, Japan, Sri Lanka, Burma, Pakistan, and Indonesia are the primary producers of Neem. Meliaceae is a family of plants that includes neem. Neem, grows in different soil types including calcareous, alkaline, dry, saline, shallow, rocky, and clay soil. Neem plants can grow up to 12-18m in height. Annual rainfall of 140-120cm is required for the cultivation of the Neem plant. The Neem plant has a lifespan of 150 to 200 years and has the best productivity after 15 years after planting[63,64]. The content of oil from Neem seed is 20-30%[64]. Physical parameters of Neem oil include density, viscosity, and heating, which are 929kg/m3 (at 15°C) and 38.875mm2/s (at 40°C) respectively (Singh et al.[44]). Also, unsaturated portions of neem include oleic acid (25-54%) and linoleic acid (6-16%), while saturated sections include stearic acid (9-24%)[63,64].

2.2.4 Rubber Seed (Hevea Brasiliensis)

Rubber seed is mostly produced in Brazil, although it is also produced in Indonesia, Malaysia, Thailand, India, and other African countries including Ghana[65]. It belongs to the Euphorbiaceae family. Rubber trees grow to be very tall, reaching up to 34m in height[52]. Rubber plant growth requires a non-frosty environment and plenty of rain. Copra, or its kernel, contains 40-50% brown oil in terms of weight, while the content of oil in the seed is about 50-60% oil[52]. The density of the rubber seed oil is 917kg/m3 (at 15°C), a heating value of 38.64MJ/kg, and a viscosity of 42.54mm2/s (at 40°C). FAs that are unsaturated such as linoleic acid (39.5%), linolenic acid (16.3%), and oleic acid (24.6%) are abundant in rubber seed oil[44].

2.2.5 Moringa Oil (Moringa oleifera)

Ben-oil tree, is another name for Moringa tree, and is native to Arabia, India, and some parts of Africa and countries in the Caribbean[66]. Dry to moist subtropical to tropical regions, with annual rainfall within a range of 25 to 300cm3 and temperatures range of 19 to 28°C makes the plant to flourish. It grows quickly and can withstand dryness, sandy soil, bacteria, and fungi. M. oleifera has several medical purposes in including to its nutritional value[67]. Within the first year following planting, ben-oil trees can produce seed pods[68]. By the second full year, complete fruit production should be expected. For several years, the trees might continue to produce pods. The oil has features like olive oil, and the degummed oil possesses properties that make it a good substitute for petroleum fuel[69]. Moringa has attracted international interest, with reports that one acre may produce 1000-2000 litres of biodiesel each year. Cetane number in the biodiesel from Moringa oil is one of the highest in biodiesel fuel, and is estimated to 67, in addition to improved oxidative stability, and a greater cloud point[70].

The indigenous tree species Allanblackia parviflora A. Chev. (Clusiaceae Lindley) is found in Ghana's rain forest regions[71,72]. The Guttiferae family includes the woody dicotyledonous plant Allanblackia parviflora[72]. Allanblackia parviflora is ever flourishing tree reaching 30m in height. The unbuttressed, straight, cylindrical bole can range in length from 30 to 80cm[73]. This species is quite similar to Allanblackia floribunda and was formerly thought to be a synonym for that species. It is now regarded as separate. The literature on the uses of each species is confused, but in practicality, each species is likely to have identical uses. The tree produces high-quality oil and has several clinical properties in the area[74]. Cultivation appears to be desirable and feasible, though it is considered a weed species in managed forestry and is eradicated. The fat extracted from the seed is used in preparation of food and is referred to as 'allanblaAllan Lacki beurre de bouandjo' in Congo. Recently, the international food industry has become interested in that as a natural solid component for margarine similar products. At room temperature, the fat in the seeds solidifies. The kernel, which accounts for around 60% of the seed, contains about 72% fat. The fat's fatty acid makeup is roughly 45-58% stearic acid and 40-51% oleic acid. Other FAs are only present in trace amounts. The fat's composition and relatively greater melting point (35°C) make it a good source for improving the steadiness of margarine substitutes for butter, and other products that are related[74].

3 LIPID-BASED BIOMASSES FROM WASTES AND BY-PRODUCTS

Biodiesel obtained from third-generation feedstocks refers to biodiesel producing microalgae and wastes oils as the feedstocks[75,76]. Less the effect of greenhouse, increased rate of growth, and yield less battle for land for farming, greater percentage of oil, and less impact on supply of food are the major advantages of third-generation biodiesel[77]. However, the major drawback is the high investment requirements, the need for sunshine, difficulty with large-scale production, and difficulties with oil extraction[78]. Biodiesel generation from algae oil is now being studied to improve the rate of production and oil extraction procedure. Sakthivel et al.[79] reported Fish oil, microalgae, animal fat, waste cooking oil, and other sources of third-generation biodiesel to be most prevalent. All these viable third-generation biodiesel resources surpass earlier-generation feedstocks in terms of food chain impact, availability, environmental adaptability, and economic feasibility. Some algal species can endure extreme conditions and have significant lipid content, which is reason microalgae could be a potential third-generation feedstock to produce biodiesel[80]. Waste oils, which include waste fish oil, waste cooking oil, and animal tallow oil which are not useful, are categorised as third generation feedstock sources for producing biodiesel. Using these feedstocks leads to a reduction in the amount being handle by the waste processing plants and less pollution of water sources. Currently, animal fats which include pork, goat, beef, and poultry are raised and used as reliable source for producing biodiesel[81].

3.1 Waste Vegetable Oils (WVO)

Vegetable oils present in practically every kitchen are WVO[82]. WVO, are not compared to pure oil from a plant are the byproduct coming from business for instance industries that process potato, companies that deals with snacks, and restaurants engaging in fast-food services[75]. Fish, yam, and ripe plantain frying, as well as small, medium, and large-scale doughnut fryers, are examples of this in Ghana. Oils from palm kernel, coconut, groundnut, and soya bean are among the vegetable oils used to fry meals in Ghana. When vegetable oils are partially hydrogenated to make margarine and vegetable shortening, trans isomers of FAs are generated. Likely, increasing the ratio of plasma low to high density lipoprotein cholesterol hurts the risk of coronary heart disease[83,84]. Vegetable oil from waste materials have two destinations in most countries: it is either dumped into local sewage systems as "ditch oil" or it is repurposed in some kitchens and utilized as raw materials for other goods. However, the volume or quantity of WVO created in Ghana is unknown (Table 4)[86]. This makes sizing a processing plant for WVO problematic. Poor WVO management also has a negative impact emitting a foul odour in the local vicinity, as well as on surface water bodies and aquatic life. WVO, when turned into biodiesel, perform best in diesel engines such as generators and CI engines in automobiles, according to studies.

Table 4. Estimated Quantities of WVO Discarded per Month by Hotels in Ghana[85]

City |

Estimated WVO Discarded per Month |

||||

No waste/Waste is Reused |

1-100L |

101-200L |

>200L |

Total |

|

Accra |

29 |

41 |

6 |

8 |

84 |

49.2% |

40.6% |

60% |

100% |

||

Kumasi |

24 |

31 |

1 |

0 |

56 |

40.7% |

30.7% |

10% |

0 |

||

Takoradi |

1 |

11 |

1 |

0 |

13 |

6.7% |

11.5% |

10% |

0 |

||

Sunyani |

1 |

6 |

1 |

0 |

8 |

1.7% |

6.2% |

10% |

0 |

||

Tamale |

4 |

12 |

1 |

0 |

17 |

|

6.7% |

11.5% |

10% |

0 |

|

3.2 Animal Fats

Animal fat is a byproduct of the meat and fisheries industries. Fish, cattle, chicken, and hogs are all sources of it[87]. Companies creating these raw materials are currently mostly using co-products obtained through animal fat to synthesize biodiesel as a result of its low pricing, notably as a fuel substitute for automotive fleets[9]. Animal fat sources are no longer allowed to be used as food due to several animal scandals and diseases. Test has been conducted for using in producing biodiesel. Tallow from infected livestock is important feedstock in producing biodiesel[88]. Because animal fat isn't generated solely for biodiesel, unreliable supply is the largest challenge for each of the feedstocks. Third-generation biodiesel is made from beef tallow or mutton, lard, yellow grease, and residues following omega FAs[89]. The leather and meat industries' primary products are as follows. These sources outperform edible oils in terms of food security, economics, and the environment. Animal waste fats with greater saturated and free FAs, on the other hand, required more complicated production processes. Waste fats from animals with less saturated FAs provide several advantages, which include a faster ignition time, better oxidation stability, and a higher calorific value[9]. These feedstocks are saturated to a high degree, resulting in a high heating value and Cetane number. Low-temperature operations is hampered by the high content FAs that are saturated (Table 5). As a result, biodiesel made from animal fats have less suitability to the cold climates.

Table 5. Fatty Acid Profile of Some Commonly Used Animal Fats[90]

Sample |

Fatty Acid Content (% w/w) |

||||||

C14:0 |

C16:0 |

C16:1 |

C18:0 |

C18:1 |

C18:2 |

C18:3 |

|

Veal |

5.751 |

23.170 |

3.158 |

13.003 |

37.778 |

6.314 |

0.589 |

Beef |

3.116 |

31.376 |

1.815 |

25.236 |

31.091 |

1.434 |

0.233 |

Lard |

1.137 |

19.794 |

2.047 |

11.814 |

44.660 |

10.867 |

0.990 |

Chicken |

0.500 |

22.055 |

6.181 |

5.050 |

40.341 |

16.515 |

0.625 |

Goose |

0.328 |

20.503 |

2.592 |

5.587 |

46.399 |

13.622 |

0.691 |

3.3 Industrial Wastes and By-products

Waste oils and fats obtained from big facilities that process food with combination of restaurant waste oils containing level of free fatty acid (FFA) levels referred as yellow grease and brown grease are important feedstock for producing biodiesel (Table 6). Waste vegetable cooking oils also referred to as yellow grease (hen the grease's FFA percentage hits 8-12%wt), have a lot of promise as a low-cost biofuel feedstock manufacturing. Waste oils can be regenerated by saponification into soap or repurposed as hydraulic fluid or lubricating oil. Frying oil that has been used, as a feedstock for producing biodiesel is however good for economic purpose. Wastewaters from various sources including slaughterhouses, compressor stations, and dairy industries are rich in fatty raw materials.

Table 6. Fatty Acid Profile of Some Commonly Used Industrial Wastes and By-products

Sample |

Fatty Acid Content (% w/w) |

|||||

C16:0 |

C18:0 |

C18:1 |

C18:2 |

C18:3 |

Others |

|

Yellow grease |

23.24 |

12.96 |

44.32 |

6.97 |

0.67 |

2.43 (C14:0) |

Brown grease |

22.83 |

12.54 |

42.36 |

12.09 |

0.82 |

1.66 (C14:0) |

Activated sludge |

28.00 |

7.50 |

24.90 |

9.50 |

2.00 |

18.00 (C16:1) 3.50 (C14:0) |

Leather industry wastes (12.2% FFA) |

20.59-28.40 |

8.36-13.23 |

40.50-42.06 |

1.80-2.97 |

0.00-0.16 |

3.05-4.20 (C14:0) |

Waste fish oil (4.90-10.7% FFA, 0.08-0.13% moisture) |

27.30-28.10 |

11.70-12.10 |

42.80-44.60 |

9.40-10.50 |

0.50-0.70 |

4.00-4.50 (C16:1) |

Tall oil |

1.00 |

3.00 |

60.00 |

32.00 |

2.00 |

1.00 (C20:3) |

Palm soap stock |

(1.1% FFA) |

47.00 |

4.50 |

42.90 |

0.2 |

1.20 (C14:0) |

Tomato seed oil |

12.26 |

5.51 |

22.17 |

56.12 |

2.77 |

|

4 LIPID-BASED BIOMASSES FROM INSECTS

Insects have become popular of late as lipid producers because of their capacity to feed on a variety of biomass sources[91]. Insects that are members of the Lepidoptera order, such as Galleria mellonella and Phases triangularis, can have a lipid percentage of more than 60%[91,92]. If fed using garbage from restaurant after extraction of the grease in portion of the solid residual, Diptera which include black soldier fly (Hermetial illucens) can create 30% lipids using their larvae state[92]. According to research, biodiesel was made utilizing triglycerides produced by black soldier fly in larvae that was fed with yellow grease extracted from restaurant garbage in a recent study[93,94]. The oil content of dried Zophobas Morio larvae was 33.80% by weight[91]. The amount of fat found in different orders, species, and even among the same species varies. Musca domestica, as an example, has a percentage range of 8.1 to 32.6% in the order Diptera[92-95]. Furthermore, larvae have a larger body fat percentage than adults[92,96]. Furthermore, the type of food consumed by insects impacts significantly on the chemical makeup of body fats. Biodiesel was created from Coleoptera larvae oil through alkaline transesterification and acid esterification[97]. In 45min of the alkaline reaction, they were able to yield biodiesel of 92.35% wt. According to the researchers of the current analysis of insect fat possibility for biodiesel generation, insects can feed on industrial, agricultural, or byproduct form urban areas across all of their life spans pile up huge doses of lipids with preferable physical and chemical characteristics, including calorific value, kinematic viscosity, and oxidation stability (FAs that ranges within C16-C18), convert and use it as a protein supplier for livestock feed (Table 7)[98]. Using insects further as biomaterials source, including as lipids, proteins, and chitin, could have a variety of uses in a chemical industry Insects could become a sustainable option in production of biomaterials like oils and fats if their breeding is linked to waste stream reduction.

Table 7. Lipid Content and Fatty Acid Profile of Selected Insect Oils[91]

Specie |

Fatty Acid Content (% w/w) |

|||||

C16:0 |

C16:1 |

C18:0 |

C18:1 |

C18:2 |

C18:3 |

|

Gnorimoschema gallaesolidaginus |

8 |

35 |

1 |

48 |

4 |

4 |

Rodophora florida |

25.3 |

1.3 |

2.8 |

54.3 |

9.7 |

6.1 |

Carpocapsa pomonella |

16 |

5 |

1 |

47 |

26 |

4 |

Acyrthosyphon pisum |

4 |

3 |

2 |

11 |

16 |

- |

Colladonus montanus |

16.7 |

0.9 |

2.4 |

63.8 |

15 |

- |

Vespula maculate |

|

15.4 |

1.5 |

53.1 |

2.4 |

1.5 |

Erycotis floridana |

28.9 |

6.4 |

1.5 |

59.1 |

- |

- |

Dendroctonus pseudotsugae |

13.2 |

23.7 |

1.8 |

59.8 |

1.1 |

- |

5 LIPID-BASED BIOMASSES FROM MICROORGANISMS

Several microorganisms from the fungi, yeast, bacteria, and Microalgae genera can accumulate significant amounts of oil, which can exceed 70% of their biomass weight under certain growing circumstances[50,99]. Oleaginous microorganisms are lipid-based biomasses with a lot of potentials, particularly in terms of production[100]. An 'oleaginous' microbe can store more dry body mass which is in form of lipids and the amount is greater than 20% as 'oil'. TAGs are the most common lipids synthesized by oleaginous organisms, but free FAs are also present[101]. Because of their high carbon-to-heteroatom ratio, lipids are an appealing feedstock for producing renewable fuels.

Algae are aquatic creatures that develop in a variety of settings[102]. Algae are grouped into two categories as follows: microalgae and microalgae. Seaweeds are microalgae, which are enormous multicellular algae that commonly thrive in ponds while microalgae are single-celled algae which live in suspension in water bodies[103]. They are a highly specialized collection of microorganisms that live in a variety of biological settings, including freshwater, and hyper-saline with a varied range of pH and temperature, as well as different nutrient availability[103]. Cyanobacteria, diatoms, green algae, golden algae, yellow-green algae, and red algae are among the primary classifications. Carbohydrates, proteins, and natural oils are the three basic elements of algal biomass[104]. Several algal species have been discovered to develop quickly and have large quantities of triglycerides (TAGs) , and are consequently known as oleaginous algae[104]. The main biochemical constituents of microalgae are lipids, proteins, polysaccharides, and nucleic acids[105]. Researchers, companies, and the general public have recently reignited their desire in using microalgae as an alternative biodiesel source[106]. Microalgae could be retrieved from an aquatic setting to create triglycerides, which could subsequently be utilized to make oil algae, a biofuel of third-generation, according to reports. These aquatic plants contain a single 6767 cell that can produce many lipids suitable for biodiesel production[107]. Two systems are employed in the cultivation of algae. The open pond system is the first, while the closed pond system is the second. Harvesting of algae can be done by flocculating or centrifugating processes, and algae can be produced in dried and semi-dried environments using these systems. Furthermore, the yield in every hectare is expected to be greater as compared to the tropical oil plants. Saline water allows thriving of algae, such as ocean water or contaminated aquifers. In industry, forestry, agriculture, and communities, this water has few competing applications. The likelihood of algae blooming adjacent to power plants is now high. Cultivating algae to produce biofuel looks simple because algae contain few prerequisites for growth. The available and concentration of micro and macronutrients, such as CO2, pH, temperature, and light are all elements that influence optimal algae growth and lipid accumulation (intensity and photoperiod). Algae react differently to these factors, particularly temperature and light. Most algae species prefer temperatures between 20 and 30 degrees Celsius. As the temperature rises, the level of FAs that is unsaturated drops, which is a physiological response. Furthermore, the kind of precursor FAs has an influence on a variety of biodiesel qualities, including melting and heating point, oxidative stability, lubricity and iodine and cetane numbers. Palmitic acid (C16:0), palmitoleic acid (C16:1), stearic acid (C18:0), oleic acid (C18:1), linoleic acid (C18:2), and linolenic acid (C18:3) are the most common goals certified for producing biodiesel (Table 8)[102]. Under limited conditions, certain microalgae change their biosynthesis process of the lipid to generate huge quantities of lipids that are neutral (20-50% dry weight), which are largely stored in cytosolic lipid bodies as triacylglycerol (TAG) (Table 9)[109]. Carbon dioxide and nitrogen oxides are the primary nutrients for algae growth, they can be nourished by CO2 emissions. The most efficient bioenergy option is algae biomass[109]. Algae have emerged as a promising contender for biofuel research because of their capacity to grow in a variety of climates[103]. Algae production techniques vary and it depends on the region of cultivation and capital cost. In comparison to photobioreactors, the raceway pond, according to literature, is a system that is techno-economic system for producing algae[110].

Table 8. Fatty Acid Profile of Some Selected Microalgae[108]

Microalgae Species |

Palmitic Acid (C16:0) |

Stearic Acid (C18:0 |

Oleic Acid (C18:1) |

Linoleic Acid (C18:2) |

Linolenic Acid (C18:3) |

Nannochloropsis oculata |

20.5 |

1.8 |

4.1 |

2.2 |

0.9 |

Scenedesmus obliquus |

27.39 |

11.88 |

32.08 |

9.08 |

8.11 |

Scenedesmus sp. |

15.62 |

2.97 |

15.23 |

7.00 |

22.99 |

Ankistrodesmus sp |

16.24 |

7.18 |

17.66 |

8.8 |

28.68 |

Ankistrodesmus falcatus |

30.23 |

2.72 |

24.79 |

2.0 |

26.86 |

Chlamydomonas reinhardtii |

17.8 |

6.85 |

32.4 |

6.58 |

16.0 |

Eustigmatophyceae Chlorella sp. |

19.03 |

2.35 |

48.21 |

1.29 |

1.54 |

Chlamydomonas sp |

50.77 |

11.54 |

13.77 |

3.93 |

2.76 |

Chlorella Vulgaris |

35.77 |

11.35 |

12.55 |

7.36 |

13.54 |

Chlorella protothecoides |

13.42 |

3.4 |

58.94 |

19.86 |

- |

Chlorella emersonii |

14.75 |

9.8 |

17.01 |

9.04 |

29.32 |

Rhodophyceae Pavlova salina |

28.6 |

0.8 |

2.0 |

8.2 |

0.7 |

Prymnesiophyceae Pavlova salina |

15.1 |

1.0 |

3.8 |

1.5 |

2.2 |

Cryptophyceae Chroomonas salina |

13.5 |

3.0 |

5.2 |

1.2 |

10.8 |

Conjugatophyceae Schizochytrium sp |

18.8 |

3.5 |

53.4 |

14.9 |

- |

Table 9. Lipid Content and Oil Productivity of Some Selected Microalgae[108]

Microalgae Species |

Oil Content (%) |

Lipid Productivity (mg/L/day) |

Nannochloropsis oculata |

22-29 |

84.0-142.0 |

Scenedesmus obliquus |

30-50 |

nd |

Scenedesmus sp. |

17-24 |

40.8-53.9 |

Ankistrodesmus sp |

11.48-31 |

nd |

Ankistrodesmus falcatus |

16.49 |

49.58 ± 5.74 |

Chlamydomonas reinhardtii |

21 |

nd |

Eustigmatophyceae Chlorella sp. |

28-53 |

42.1 |

Chlamydomonas sp |

22.7 |

nd |

Chlorella Vulgaris |

41-58 |

11.2-40.0 |

Chlorella protothecoides |

40-60 |

1214 |

Chlorella emersonii |

23-63 |

10.3-50.0 |

Rhodophyceae Pavlova salina |

9-14 |

34.8 |

Prymnesiophyceae Pavlova salina |

12-30 |

49.4 |

Cryptophyceae Chroomonas salina |

12-14.5 |

nd |

Conjugatophyceae Schizochytrium sp |

50-77 |

19-35 |

Notes: nd, not determined.

5.2.2 Yeast

Oleaginous yeasts, store lipids beyond 20% of their dry matter and 70% under nutrient-reducing circumstances, are another promising option for making biodiesel[120]. These microorganisms have a faster growth rate and a higher lipid composition than microalgae, with most of the lipids being triglycerides[91]. As a carbon source, yeast can thrive on a variety of sugar-rich media (glucose, xylose, arabinose, and mannose)[121]. The quantity of oil produced depends on the species of the yeast, substrate, and mode of culture. Candida sp, Cryptococcus sp, Lipomyces sp, and Rhodotorula sp, are part of the species of the yeast that have the greatest ability in lipid collections[122]. Linolenic (1-3% weight), linoleic (3-24% weight), oleic (28-66% weight), Palmitic (11-37% wt), palmitoleic (1-6% weight), and stearic (1-10% weight acids make up most of their fatty acid composition[91]. The fatty acid composition is strongly affected by the substrate used to create yeast oil. When using thin stillage and glycerol as nitrogen and carbon sources in Rhodotorula glutinis, the quantity of oleic acid produced was higher than when yeast extract was utilized as a nitrogen source[123]. As a result, choosing the right substrate is crucial for producing biodiesel from oil with the right fatty acid makeup. When using submerged batch fermentation, lipid accumulation occurs in three phases: production of carbohydrate and lipid during the depletion of the nitrogen source, turning over the accumulated lipids during the complete depletion of the carbon source and growing exponentially during the availability of nitrogen and carbon sources[124]. Manufacturing yeast oil is far additional costly than generating vegetable oil since the biomasses used for making the yeast are valuable industrial products[125]. The research that is conducted currently is focused on finding oleaginous yeasts that could survive on waste and lignocellulosic material[126]. Apart from waste recycling, this might assist in lower manufacturing costs, transferring yeast oil into a possible feedstock for the biodiesel industry. Crude glycerol (a biodiesel waste product) has been proposed as a substrate for Cryptococcus curvatus, and Rhodotorula glutinis TISTR 5159124 yeast[127]. The two yeasts can collect up to 60.7 percent and 48 percent lipids in dry cell weight under these conditions. Lignocellulosic material is another common waste that can be utilized to make yeast oil (composed of cellulose, lignin, and hemicellulose). Therefore, Cryptococcus curvatus can provide a dry cell with lipid content of around 72%[128]. The suitability of a substrate by using waste oil to manufacture lipids using Yarrowia lipolytica was investigated also, with a lipid accumulation rate of up to 57.89%[129]. According to Axelsson et al.[130] currently there is one pilot facility in Europe, Finland, and Porvoo produce oil from yeast and trash. The microbial oil for commercial purposes is not available, and the first industrial application is envisaged in 5-10 years.

5.3 Bacteria

Bacteria are unicellular microorganisms with a rapid growth rate (high production within 12-24h) when cultured using a simple method[131]. Furthermore, even in organisms that do not normally create many FAs, genetic engineering rapidly raises the manufacturing of lipids in prokaryotes like bacteria[132]. In this regard, some researchers were able to produce 2.5g/L of FAs by modifying the E. coli genome, mostly regarding FFA content (50%). Through a direct esterification reaction, research on genetic engineering is focusing on increasing FFA production to reduce synthesis of glycerol[133]. Both Gram-negative and Gram-positive bacteria have been identified to produce TAG and accumulate it intracellularly. However, this power appears to be limited. Most bacteria create complex lipids, but only a few are capable of producing oils that can be utilized as biodiesel feedstock[134]. Recent research has been conducted on the utilization of oleaginous bacteria as a raw material for biodiesel manufacturing[135]. Bacterial TAG content variation depends on the microbe and the sources of carbon, but oleic (C18:1) and hexadecanoic acid (C16:0) are the most common[136]. Nonetheless, bacteria from the Gordonia genus has ability of accumulating greater than 70% of TAG with a mixture of caproic (C6:0) and behenic acid (C22:0) when grown on orange trash (Table 10)[135]. Jones et al.[139] discovered that bacteria collect lesser quantities of lipids than microalgae and that only a few genera of the Actynomycetes class, such as Mycobacterium and Streptomyces, may carry out accumulation of large levels of TAG. Other bacteria develop TAG during its cultivations on a simple carbon source under stressful circumstances, however, Streptomyces accumulates TAG only when the nitrogen supply is absent. Rhodococcus opacus has been investigated due its potential to collect higher than 80% TAG in cell dry weight[140]. This species has recently been discovered to produce up to 59.26mg/L/day of TAG when grown entirely on carob waste[141]. Furthermore, Rhodococcus opacus DSM1069 has been proven to break down and thrive on substances derived from lignin for example coniferyl alcohol[38]. There are no studies that show this species can manufacture TAG from lignin feedstocks. The only Gram-negative oleaginous genus with high lipid production for biodiesel generation is Acitenobacter[142]. Other Gram-negative bacteria, such as Pseudomonas spp., have had their lipid production studied using glucose as a substrate, with a lipid concentration of up to 40%[143]. However, because of the low amount of TAG produced and the difficulty of extracting the bacterial lipoid produced in the outer membrane, heterotrophic bacteria are still used as a raw material for biodiesel production on a laboratory scale[144].

Table 10. Lipid Content, and Oil Productivity of Selected Yeasts, Fungi, and Bacteria[137,138]

Yeasts, Fungi, and Bacterial Specie |

Lipid Content (% w/w) |

Lipid Productivity (mg/L/day) |

Yeast |

|

|

Rhodosporidium toruloides |

38 |

120 |

Cryptococcus albidus |

65 |

- |

Cryptococcus musci |

44.7 |

370 |

Cryptococcus podzolicus |

31.8 |

90 |

Lipomyces starkeyi |

42-64 |

140 |

Trichosporon porosum |

34.1 |

100 |

Rhodotorula glutinis |

72 |

- |

Cryptococcus curvatus |

58 |

- |

Yarrowia lipolytica |

36 |

- |

Fungi |

|

|

Aspergillus oryzae |

26-57 |

- |

Cunninghamella echinulata |

48.6 |

- |

Mortierella isabellina |

50-86 |

- |

Bacterial |

|

|

Rhodococcus opacus |

14-93 |

- |

Bacillus subtilis |

39.8 |

- |

Serratia sp |

66.7 |

- |

Gordonia sp |

60-72 |

- |

6 RECOMMENDATIONS AND BIOFUELS PRODUCTION PROSPECTS FOR SECOND-GENERATION LIPID-BASED BIOMASSES

Energy is essential for maintaining economic growth and human growth standards. After the industrial sector, transportation uses 30% of all delivered energy. However, many academics are looking into the idea of using alternative fuels due to the predicted decrease in fossil fuels and the environmental problems involved with burning them. Biodiesel is a resource that has a lot of potentials. Concerns over the food vs. fuel debate, as well as the production cost argument due to high feedstock price, had raised from the use of edible oil as a feedstock. As a result, demand for non-edible oil as a biodiesel feedstock is rising rapidly. Due to the inclusion of hazardous components, non-edible oil is not acceptable for human consumption. Furthermore, non-edible oil plants can grow in non-fertile, harsh areas with low moisture requirements, which are not appropriate for growing edible crops. Non-edible oil's physicochemical qualities and fatty acid compositions are equivalent to edible oil's properties and fatty acid compositions. As a result, there is more than enough potential for non-edible oil to be used as a biodiesel feedstock. The biggest impediment to using non-edible oil as a viable feedstock is the high FFA and water content in non-edible oil. However, non-edible oil extracted using the scCO2 extraction technique yielded non-edible oil with low FFA content and moisture content. As a result, one of the most significant advantages of producing biodiesel is the vast range of accessible biomasses. As a result, choosing the optimum feedstock is critical for ensuring cheap biodiesel production costs.

7 CONCLUSION

The focus of this review is on lipid-based biomasses that are available in Ghana as biofuel feedstocks. The analysis reveals that the country has a diverse range of lipid-based biomass resources, as well as a significant advantage or their transformation to different kinds of biofuels utilizing currently existing biomass transformation technology. Different types of edible oil plants, non-edible oil plants, waste vegetables, animal fats, industrial wastes, and by-products, and lipid-based biomasses from insects' microalgae, fungi, yeasts, and bacteria are all available in Ghana, making them potential biofuel feedstocks, especially for second-generation biofuels which have low competition with other uses. In addition to biofuel processing technology, the source of lipid-based biomasses has a considerable impact on the price of the biofuel produced. The price of biofuels made from lipid-based biomasses determines their economic compatibility. As a result, lowering the cost of 2nd generation feedstocks and processing, particularly downstream processing, is critical for obtaining long-term lipid-based biomass resources.

Acknowledgements

I acknowledge Michael Aboah for proof reading the manuscript.

Conflicts of Interest

The authors declared that there are no conflict of interest.

Author Contribution

The authors confirm contribution to the paper as follows: study conception: Takase M, Kipkoech R, Irungu Kamau F, Kibet J, and Mugah F. Draft manuscript preparation: Takase M, Kipkoech R, Irungu Kamau F, Kibet J, and Mugah F. All authors reviewed and approved the final version of the manuscript.

Abbreviation List

CI, Compression ignition

FAs, Fatty acids

FFA, Free fatty acid

TAGs, Triacylglycerols

WVO, Waste vegetable oils

References

[1] Avtar R, Tripathi S, Aggarwal AK et al. Population-urbanization-energy nexus: a review. Resources, 2019; 8: 136.[DOI]

[2] Noorollahi Y, Pourarshad M, Veisi A. The synergy of renewable energies for sustainable energy systems development in oil-rich nations; case of Iran. Renew Energ, 2021; 173: 561-568.[DOI]

[3] Delvi MK, Soudagar MEM, Khan H et al. Biodiesel production utilizing diverse sources, classification of oils and their esters, performance and emission characteristics: A research. IJRTE, 2019; 8: 976-983.[DOI]

[4] Ruan R, Zhang Y, Chen P et al. Biofuels: Introduction. In: Pandey A, Larroche C, Gnansounou E ed. Biofuels: Alternative Feedstocks and Conversion Processes for the Production of Liquid and Gaseous Biofuels (Second Edition), 2019; 3-43.[DOI]

[5] Ibrahim ML, Khalil NNANA, Islam A et al. Preparation of Na2O supported CNTs nanocatalyst for efficient biodiesel production from waste-oil. Energ Convers Manage, 2020; 205: 112445.[DOI]

[6] Atabani AE, Silitonga AS, Ong HC et al. Non-edible vegetable oils: a critical evaluation of oil extraction, fatty acid compositions, biodiesel production, characteristics, engine performance and emissions production. Renew Sust Energ Rev, 2013; 18: 211-245.[DOI]

[7] Axelsson L, Franzén M, Ostwald M et al. Jatropha cultivation in southern India: assessing farmers' experiences. Biofuel Bioprod Bior, 2012; 6: 246-256.[DOI]

[8] Mittelbach M. Fuels from oils and fats: Recent developments and perspectives. Eur J Lipid Sci Tech, 2015; 117: 1832-1846.[DOI]

[9] Singh D, Sharma D, Soni SL et al. A review on feedstocks, production processes, and yield for different generations of biodiesel. Fuel, 2020; 262: 116553.[DOI]

[10] Niculescu R, Clenci A, Iorga-Siman V. Review on the use of diesel-biodiesel-alcohol blends in compression ignition engines. Energies, 2019; 12: 1194.[DOI]

[11] Dwivedi G, Jain S, Sharma MP. Diesel engine performance and emission analysis using biodiesel from various oil sources-Review. J Mater Environ Sci, 2013; 4: 434-447.

[12] Man XJ, Cheung CS, Ning Z et al. Influence of engine load and speed on regulated and unregulated emissions of a diesel engine fueled with diesel fuel blended with waste cooking oil biodiesel. Fuel, 2016; 180: 41-49.[DOI]

[13] Khatib H. IEA world energy outlook 2011-A comment. Energ policy, 2012; 48: 737-743.[DOI]

[14] Cronshaw I. World Energy Outlook 2014 projections to 2040: natural gas and coal trade, and the role of China. Aust J Agr Resour Ec, 2015; 59: 571-585.[DOI]

[15] IRENA. International Renewable Energy Agency. Accessed 2022. Available at:[Web]

[16] Noor CWM, Noor MM, Mamat R. Biodiesel as alternative fuel for marine diesel engine applications: A review. Renew Sust Energ Rev, 2018; 94: 127-142.[DOI]

[17] Yang L, Takase M, Zhang M et al. Potential non-edible oil feedstock for biodiesel production in Africa: a survey. Renew Sust Energ Rev, 2014; 38: 461-477.[DOI]

[18] Yilmaz N, Atmanli A. Experimental assessment of a diesel engine fueled with diesel-biodiesel-1-pentanol blends. Fuel, 2017; 191: 190-197.[DOI]

[19] Khaligh NG, Hamid SBA, Mihankhah T. Eco-friendly biodiesel production from waste olive oil by transesterification using nano-tube TiO2: Proceedings of the International Conference of Social Science, Medicine and Nursing, Istanbul, Turkey, 5-6 June 2015.

[20] Alalwan HA, Alminshid AH, Aljaafari HAS. Promising evolution of biofuel generations. Subject review. Renew Energ Focus, 2019; 28: 127-139.[DOI]

[21] Chong CT, Loe TY, Wong KY et al. Biodiesel sustainability: The global impact of potential biodiesel production on the energy-water-food (EWF) nexus. Environ Technol Inno, 2021; 22: 101408.[DOI]

[22] Akusu OM, Wordu GO, Obiesie C. Effects of fat modification on the physicochemical properties and fatty acid profile of shortenings formulated with african pear (Dacryodes edulis) pulp oil and tallow tree (Allanblackia floribunda) seed oil. Int J Nutr Sci & Food Tech, 2019; 5: 12-19.

[23] Yeboah SO, Mitei YC, Ngila JC et al. Compositional and structural studies of the oils from two edible seeds: Tiger nut, Cyperus esculentum, and asiato, Pachira insignis, from Ghana. Food Res Int, 2012; 47: 259-266.[DOI]

[24] Mahmoud AA, Mohdaly AAA, Elneairy NAA. Wheat germ: an overview on nutritional value, antioxidant potential and antibacterial characteristics. Food Nutr Sci, 2015; 6: 265.[DOI]

[25] Kamran E, Mashhadi H, Mohammadi A et al. Biodiesel production from Elaeagnus angustifolia. L seed as a novel waste feedstock using potassium hydroxide catalyst. Biocatal Agr Biotech, 2020; 25: 101578.[DOI]

[26] Sawangkeaw R, Ngamprasertsith S. A review of lipid-based biomasses as feedstocks for biofuels production. Renew Sust Energ Rev, 2013; 25: 97-108.[DOI]

[27] Mensah E, Obeng GY. Assessment and projection of waste vegetable oils from hotels for biodiesel feedstock and CO2 savings in Ghana. Int J Eng Res Sci Technol, 2013; 2: 4.

[28] Nina GC, Ukeyima M, Ogori AF et al. Investigation of physiochemical and storage conditions on the properties of extracted tiger nut oil from different cultivars. J Microb Biotec Food, 2020; 9: 988-993.[DOI]

[29] Kuss VV, Kuss AV, da Rosa RG et al. Potential of biodiesel production from palm oil at Brazilian Amazon. Renew Sust Energ Rev, 2015; 50: 1013-1020.[DOI]

[30] Munasinghe M, Jayasinghe P, Deraniyagala Y et al. Value-Supply Chain Analysis (VSCA) of crude palm oil production in Brazil, focusing on economic, environmental and social sustainability. Sustain Prod Consump, 2019; 17: 161-175.[DOI]

[31] Mekhilef S, Siga S, Saidur R. A review on palm oil biodiesel as a source of renewable fuel. Renew Sust Energ Rev, 2011; 15: 1937-1949.[DOI]

[32] Imoisi OB, Ilori GE, Agho I et al. Palm oil, its nutritional and health implications. J Appl Sci Environ Manage, 2015; 19: 127-133.[DOI]

[33] Murugesan P, Aswathy GM, Kumar KS et al. Oil palm (Elaeis guineensis) genetic resources for abiotic stress tolerance: A review. Indian J Agr Sci, 2017; 87: 571-579.

[34] Rethinam P, Murugesan P. Global perspective of germplasm and breeding for seed production in oil palm. Int J Oil Palm, 2018; 10: 17-34.

[35] Twerefou DK, Chinowsky P, Adjei-Mantey K et al. The economic impact of climate change on road infrastructure in Ghana. Sustainability, 2015; 7: 11949-11966.[DOI]

[36] Popoola L, Larwanou M, Jimoh SO. Biofuel initiatives in West Africa and the Sahel: potential for success. Int Forest Rev, 2015; 17: 136-148.[DOI]

[37] Pfister M, Saha S. Effects of biochar and fertilizer management on sunflower (Helianthus annuus L.) feedstock and soil properties. Arch Agron Soil Sci, 2017; 63: 651-662.[DOI]

[38] C Sharma Y, Singh B, Madhu D et al. Fast synthesis of high quality biodiesel from ‘waste fish oil’by single step transesterification. Biofuel Res J, 2014; 1: 78-80.[DOI]

[39] Dorni C, Sharma P, Saikia G et al. Fatty acid profile of edible oils and fats consumed in India. Food Chem, 2018; 238: 9-15.[DOI]

[40] Kostić MD, Veličković AV, Joković NM et al. Optimization and kinetic modeling of esterification of the oil obtained from waste plum stones as a pretreatment step in biodiesel production. Waste Manage, 2016; 48: 619-629.[DOI]

[41] Chhetri AB, Tango MS, Budge SM et al. Non-edible plant oils as new sources for biodiesel production. Int J Mol Sci, 2008; 9: 169-180.[DOI]

[42] Mahmudul HM, Hagos FY, Mamat R et al. Production, characterization and performance of biodiesel as an alternative fuel in diesel engines-A review. Renewable Sustainable Energy Rev, 2017; 72: 497-509.[DOI]

[43] Yuan K, Reckling M, Ramirez MDA et al. Characterization of rhizobia for the improvement of soybean cultivation at cold conditions in central Europe. Microbes Environ, 2020; 35: ME19124.[DOI]

[44] Singh D, Sharma D, Soni SL et al. Chemical compositions, properties, and standards for different generation biodiesels: A review. Fuel, 2019; 253: 60-71.[DOI]

[45] Kyereh D, Maňourová A, Hendre PS et al. Diversity, Chemical Composition, and Domestication Potential of Allanblackia parviflora A. Chev. in West Africa. Forests, 2021; 12: 1758.[DOI]

[46] Watanabe S, Yoshikawa S, Sato K. Formation and properties of dark chocolate prepared using fat mixtures of cocoa butter and symmetric/asymmetric stearic-oleic mixed-acid triacylglycerols: Impact of molecular compound crystals. Food Chem, 2021; 339: 127808.[DOI]

[47] Takase M, Essandoh PK, Kipkoech R. New non-edible Allanblackia parviflora seed oil as an alternative feedstock for biodiesel production and characterization of the fuel. Discov Sustain, 2021; 2: 1-9.[DOI]

[48] Bhuiya MMK, Rasul MG, Khan MMK et al. Prospects of 2nd generation biodiesel as a sustainable fuel-Part: 1 selection of feedstocks, oil extraction techniques and conversion technologies. Renewable Sustainable Energy Rev, 2016; 55: 1109-1128.[DOI]

[49] Olar HR, Halafawi M, Avram L. Petroleum and Coal. Pet Coal, 2021; 63: 278-283.

[50] Rawat I, Kumar RR, Mutanda T et al. Biodiesel from microalgae: a critical evaluation from laboratory to large scale production. Appl Energy, 2013; 103: 444-467.[DOI]

[51] Datta A, Hossain A, Roy S. An overview on biofuels and their advantages and disadvantages. 2019; 31: 1851-1858.[DOI]

[52] Shaah MAH, Hossain MS, Allafi FAS et al. A review on non-edible oil as a potential feedstock for biodiesel: physicochemical properties and production technologies. RSC Adv, 2021; 11: 25018-25037.[DOI]

[53] Udo MD, Ekpo U, Ahamefule FO. Effects of processing on the nutrient composition of rubber seed meal. J Saudi Soc Agric Sci, 2018; 17: 297-301.[DOI]

[54] Tabashnik BE, Carrière Y. Global patterns of resistance to Bt crops highlighting pink bollworm in the United States, China, and India. J Econ Entomol, 2019; 112: 2513-2523.[DOI]

[55] Amanet K, Emmanuel OC, Quansah GW et al. Cotton Production in Africa. In: Cotton Production, Jabran K, Chauhan BS ed. John Wiley & Sons: Hoboken, USA, 2019; 359-369.[DOI]

[56] Krist S. Vegetable fats and oils. Springer Nature: Cham, Switzerland, 2020.[DOI]

[57] Kumar P, Srivastava VC, Jha MK. Jatropha curcas phytotomy and applications: Development as a potential biofuel plant through biotechnological advancements. Renewable Sustainable Energy Rev, 2016; 59: 818-838.[DOI]

[58] Singh B, Singh K, Rao GR et al. Agro-technology of Jatropha curcas for diverse environmental conditions in India. Biomass Bioenergy, 2013; 48: 191-202.[DOI]

[59] Saleem H, Ahmad I, Shahid MN et al. In vitro acetylcholinesterase and butyrylcholinesterase inhibitory potentials of Jatropha gossypifolia plant extracts. Acta Pol Pharm, 2016; 73: 419-423.

[60] Shambhu VB, Bhattacharya TK, Nayak LK et al. Studies on characterization of raw Jatropha oil and its biodiesels with relevance of diesel. Int J Emerg Tech Adv Eng, 2013; 3: 48-54.

[61] Thapa S, Indrawan N, Bhoi PR. An overview on fuel properties and prospects of Jatropha biodiesel as fuel for engines. Environ Technol Innovation, 2018; 9: 210-219.[DOI]

[62] Vilas Bôas RN, Mendes MF. A review of biodiesel production from non-edible raw materials using the transesterification process with a focus on influence of feedstock composition and free fatty acids. J Chil Chem Soc, 2022; 67: 5433-5444.[DOI]

[63] Ikram MM, Hanif MA, Khan GS et al. Significant seed oil feedstocks for renewable production of biodiesel: a review. Curr Org Chem, 2019; 23: 1509-1516.[DOI]

[64] Omowanle J, Ayo RJ, Habila J et al. Physico-chemical and Gc-Ms Analysis of some selected plant seed oils; Castor, Neem and Rubber Seed Oils. FUW Trends Sci Technol J, 2018; 3: 644-651.[DOI]

[65] Benya E G. Tree Crops. BioScience, 1980; 30: 5-6.[DOI]

[66] Boukandoul S, Casal S, Zaidi F. The potential of some moringa species for seed oil production. Agriculture, 2018; 8: 150.[DOI]

[67] Fahey JW. Moringa oleifera: A review of the medicinal potential. Int Sym Moringa, 2017; 1158: 209-224.[DOI]

[68] Meireles D, Gomes J, Lopes L et al. A review of properties, nutritional and pharmaceutical applications of Moringa oleifera: integrative approach on conventional and traditional Asian medicine. Adv Tradit Med, 2020; 20: 495-515.[DOI]

[69] Gharsallah K, Rezig L, Msaada K et al. Chemical composition and profile characterization of Moringa oleifera seed oil. S Afr J Bot, 2021; 137: 475-482.[DOI]

[70] Niju S, Balajii M, Anushya C. A comprehensive review on biodiesel production using Moringa oleifera oil. Int J Green Energy, 2019; 16: 702-715.[DOI]

[71] Ofori DA, Asomaning JM, Peprah T et al. Addressing constraints in propagation of Allanblackia spp. through seed sectioning and air layering. J Exp Biol Agric Sci, 2015; 3: 89-96.

[72] Tchinmegni F, Tsobeng A, Ngonkeu E et al. Valorisation of non-timber forest product: case of Allanblackia floribunda Oliver. Int J Res Pharm Biosci, 2016; 3: 9-20.

[73] Ogunkunle O, Ahmed NA. Overview of biodiesel combustion in mitigating the adverse impacts of engine emissions on the sustainable human-environment scenario. Sustainability, 2021; 13: 5465.[DOI]

[74] Crockett S L. Allanblackia oil: Phytochemistry and use as a functional food. Int J Mol Sci, 2015; 16: 22333-22349.[DOI]

[75] Nanda S, Rana R, Sarangi PK et al. A broad introduction to first-, second-, and third-generation biofuels. In: Sarangi P, Nanda S, Mohanty P ed. Recent Advancements in Biofuels and Bioenergy Utilization. Springer, Singapore, 2018; 1-25.[DOI]

[76] Naeini MA, Zandieh M, Najafi SE et al. Analyzing the development of the third-generation biodiesel production from microalgae by a novel hybrid decision-making method: The case of Iran. Energy, 2020; 195: 116895.[DOI]

[77] Shiru S, Shiru MS. Towards Commercialization of Third‐Generation Biofuel Industry for Sustainable Energy Production in Nigeria. Chem Bio Eng Rev, 2021; 8: 593-611.[DOI]

[78] Jabin S, Kapoor JK. Role of Polyelectrolytes in the Treatment of Water and Wastewater. Sustainable Green Chemical Processes and their Allied Applications, 2020; 289-309.[DOI]

[79] Sakthivel R, Ramesh K, Purnachandran R et al. A review on the properties, performance and emission aspects of the third generation biodiesels. Renew Sustain Energ Rev, 2018; 82: 2970-2992.[DOI]

[80] Ananthi V, Raja R, Carvalho IS et al. A realistic scenario on microalgae based biodiesel production: Third generation biofuel. Fuel, 2021; 284: 118965.[DOI]

[81] Tamjidi S, Esmaeili H, Moghadas BK. Performance of functionalized magnetic nanocatalysts and feedstocks on biodiesel production: a review study. J Clean Prod, 2021; 305: 127200.[DOI]

[82] Sangkharak K, Khaithongkaeo P, Chuaikhunupakarn T et al. The production of polyhydroxyalkanoate from waste cooking oil and its application in biofuel production. Biomass Convers Bior, 2021; 11: 1651-1664.[DOI]

[83] Franco-Arellano B, Arcand JA, Kim MA et al. Progress towards eliminating industrially produced trans-fatty acids in the Canadian marketplace, 2013-2017. Public Health Nutr, 2020; 23: 2257-2267.[DOI]

[84] Oteng A B, Kersten S. Mechanisms of action of trans fatty acids. Adv Nutr, 2020; 11: 697-708.[DOI]

[85] E Mensah, Obeng GY. Assessment and projection of waste vegetable oils from hotels for biodiesel feedstock and CO2 savings in Ghana. Int J Eng Res Sci Technol, 2013; 2: 4.

[86] Okuley A. Assessment of Biofuel Potential on Marginal Lands and from Waste Vegetable Oil Resources in a Ghana [master's thesis]. Yaoundé, Cameroun: Pan African University Institute For Water and Energy Sciences; 2019.

[87] Zhang Y, Zhang J, Simpson BK. An Introduction to agricultural and fishery wastes. In: Simpson B K, Aryee ANA, Toldra F ed. Byproducts from Agriculture and Fisheries: Adding Value for Food, Feed, Pharma, and Fuels. John Wiley & Sons Ltd.: Hoboken, USA, 2019; 1-17.[DOI]

[88] Mozhiarasi V, Natarajan TS. Slaughterhouse and poultry wastes: Management practices, feedstocks for renewable energy production, and recovery of value added products. Biomass Conv Bioref, 2022; 1-24.[DOI]

[89] Ramos M, Dias APS, Puna JF et al. Biodiesel production processes and sustainable raw materials. Energies, 2019; 12: 4408.[DOI]

[90] Sander A, Petračić A, Parlov Vuković J et al. From coffee to biodiesel—deep eutectic solvents for feedstock and biodiesel purification. Separations, 2020; 7: 22.[DOI]

[91] Pinzi S, Leiva D, López‐García I et al. Latest trends in feedstocks for biodiesel production. Biofuel Bioprod Bior, 2014; 8: 126-143.[DOI]

[92] Manzano-Agugliaro F, Sanchez-Muros MJ, Barroso FG et al. Insects for biodiesel production. Renew Sust Energ Rev, 2012; 16: 3744-3753.[DOI]

[93] Wang C, Qian L, Wang W et al. Exploring the potential of lipids from black soldier fly: New paradigm for biodiesel production. Renew Energ, 2017; 111: 749-756.[DOI]

[94] Ishak S, Kamari A. Biodiesel from black soldier fly larvae grown on restaurant kitchen waste. Environ Chem Lett, 2019; 17: 1143-1150.[DOI]

[95] Barroso FG, Sánchez-Muros MJ, Segura M et al. Insects as food: Enrichment of larvae of Hermetia illucens with omega 3 fatty acids by means of dietary modifications. J Food Compos Anal, 2017; 62: 8-13.[DOI]

[96] Reis T, Van Gilst MR, Hariharan IK. A buoyancy-based screen of Drosophila larvae for fat-storage mutants reveals a role for Sir2 in coupling fat storage to nutrient availability. Plos Genet, 2010; 6: e1001206.[DOI]

[97] Raksasat R, Lim JW, Kiatkittipong W et al. A review of organic waste enrichment for inducing palatability of black soldier fly larvae: Wastes to valuable resources. Environ Pollut, 2020; 267: 115488.[DOI]

[98] Franco A, Salvia R, Scieuzo C et al. Lipids from insects in cosmetics and for personal care products. Insects, 2021; 13: 41.[DOI]

[99] Kumar D, Singh B, Korstad J. Utilization of lignocellulosic biomass by oleaginous yeast and bacteria for production of biodiesel and renewable diesel. Renew Sustain Energ Rev, 2017; 73: 654-671.[DOI]

[100] Dhanasekaran D, Sundaresan M, Suresh A et al. Oleaginous microorganisms for biofuel development. Environ Sci & Engg, 2017; 12: 243-263.

[101] Liang MH, Jiang JG. Advancing oleaginous microorganisms to produce lipid via metabolic engineering technology. Prog Lipid Res, 2013; 52: 395-408.[DOI]

[102] Demirbas A, Demirbas MF. Importance of algae oil as a source of biodiesel. Energ Convers Manage, 2011; 52: 163-170.[DOI]

[103] Jalilian N, Najafpour GD, Khajouei M. Macro and micro algae in pollution control and biofuel production-a review. Chem Bio Eng Rev, 2020; 7: 18-33.[DOI]

[104] Bhardwaj N, Agrawal K, Verma P. Algal biofuels: an economic and effective alternative of fossil fuels. In: Srivastava N, Srivastava M, Mishra PKed, Microbial strategies for techno-economic biofuel production, Springer Nature, Singapore, 2020; 207-227.[DOI]

[105] Sajjadi B, Chen WY, Raman AAA et al. Microalgae lipid and biomass for biofuel production: A comprehensive review on lipid enhancement strategies and their effects on fatty acid composition. Renew Sust Energ Rev, 2018; 97: 200-232.[DOI]

[106] Ranjbari M, Esfandabadi ZS, Ferraris A et al. Biofuel supply chain management in the circular economy transition: An inclusive knowledge map of the field. Chemosphere, 2022; 296: 133968.[DOI]

[107] Enamala MK, Enamala S, Chavali M et al. Production of biofuels from microalgae-A review on cultivation, harvesting, lipid extraction, and numerous applications of microalgae. Renew Sust Energ Rev, 2018; 94: 49-68.[DOI]

[108] Xue Z, Yu Y, Yu W et al. Development prospect and preparation technology of edible oil from microalgae. Front Mar Sci, 2020; 7: 402.[DOI]

[109] Hussain F, Shah SZ, Ahmad H et al. Microalgae an ecofriendly and sustainable wastewater treatment option: Biomass application in biofuel and bio-fertilizer production. A review. Renew Sust Energ Rev, 2021; 137: 110603.[DOI]

[110] Valdovinos-García EM, Petriz-Prieto MA, Olán-Acosta MÁ et al. Production of microalgal biomass in photobioreactors as feedstock for bioenergy and other uses: A techno-economic study of harvesting stage. Appl Sci, 2021; 11: 4386.

[111] Yao Q, Chen H, Wang S et al. An efficient strategy for screening polyunsaturated fatty acid-producing oleaginous filamentous fungi from soil. J Microbiol Meth, 2019; 158: 80-85.[DOI]