Synthesis of Biodegradable Plastic from Household Organic Waste

Rhythm Niranjani1, Janki Govani2, Pankaj Pathak3*

1Department of Hydroscience and Engineering, Technical University of Dresden, Dresden, Germany

2Deloitte Touche Tohmatsu India LLP, Mumbai, India

3Department of Environmental Science, SRM University AP, Andhra Pradesh, India

*Correspondence to: Pankaj Pathak, PhD, Assistant Professor, Department of Environmental Science, SRM University AP, Mangalagiri-Mandal, Neeru Konda, Amaravati, Andhra Pradesh 522502, India; Email: pankajpathak18@gmail.com

Abstract

Objective: Bioplastic is synthesized from organic substances and is biodegradable in nature. It can solve the environmental problems associated with petroplastic and secure the future through prominent research efforts and growing environmental concerns. Though, in India, bioplastics are still in their infancy.

Methods: It is currently facing various challenges such as strength, feasibility, and cost of synthesis. Moreover, markets are less aware of the concept and potentiality of bioplastics. In this study, bioplastics were prepared using household solid waste by extracting starch from potato and banana peels and further adding plasticisers.

Results: The water-holding capacity and tensile strength of the synthesized plastic are 0.7wt% and 23.17MPa, respectively, which are comparable to commercially available plastic.

Conclusion: This study describes the synthesis of bio-degradable plastic using vegetable waste and has significant applications in mulch farming.

Keywords: bioplastic, biodegradable, synthesis, waste

1 INTRODUCTION

Petroplastics (or fossil-based plastics) are widely used due to their simplicity. However, they generally have severe environmental impacts. It is noted that the disposal of plastics in the ocean and ground poses a severe environmental concern such as microplastics[1-3]. Harmful impacts of plastics such as bioaccumulation and biomagnification are noticed on sea creatures such as plankton, and fish as well as on human beings i.e. cancer, immune disorders, and birth defects[4,5]. Therefore, exploration for a substitute for harmful plastics, i.e. biodegradable plastics is of great significance[6-10]. In this context, bioplastics can serve the purpose as they are derived from renewable biomass sources, such as vegetable fats and oils, corn starch, straw, woodchips, food waste, or any other relevant matter[11-13]. The major advantages of using bioplastics over plastics are that bioplastics produce much lower carbon footprints and feature lower energy costs for manufacturing, and that using bioplastics ultimately reduces litter and increases composability[14]. In addition, bioplastics can be broken down in the environment by microorganisms in a biodegradable manner[15]. This process produces CO2 and water under aerobic conditions or CH4 under anaerobic conditions (in the absence of air) such as in a landfill.

Furthermore, it should also be noted that the biodegradation of plastics not only depends on the resource material but is linked with its chemical structure. In other words, neither 100% bioplastics are biodegradable nor 100% petroplastics are non-biodegradable[16]. For a better understanding, some properties of bioplastics and petroplastics are mentioned in Table 1.

Table 1. The Comparison between Bioplastic and Petroplastics

Properties |

Bioplastic |

Petroplastic |

Renewable |

Yes/partially |

No |

Sustainable |

Yes |

No |

Breakdown in environment |

Biodegradable/compostable |

Degradable but some polymer oxidation |

Polymer range |

Limiting but growing |

Extensive |

GHG Emission |

Usually low |

Relatively high |

Fossil fuel usage |

Usually low |

Relatively high |

This study describes the synthesis of bioplastic. However, the production of petroplastics tends to require the mining of more fossil fuels and produces more greenhouse gases in the environment. In contrast, the production of bioplastics minimizes these factors, reducing the requirements for fossil fuels and the emission of greenhouse gases. Our goal is to synthesize such an effective bioplastic that can be cost-effective and utilized in different applications[13].

2 MATERIALS AND METHODS

2.1 Synthesis of Bioplastic

Several studies have been performed to synthesise and characterize bioplastics. Song et al. described the method of improving tensile strength of bioplastic made from starch by adding wheat gluten (WG) as a plasticizer and hydrophobic liquid[8]. WG has similar physical properties as hydrophobic chemicals as it does not absorb water. The use of castor oil renders the bioplastic water-resistant and increases its tensile strength. Furthermore, bioplastic can also be synthesized from agricultural waste[17,18]. This waste mainly contained flax fibers and cotton linters. Compounds such as polyethylene glycol as a plasticizer and glacial acetic acid, and acetic anhydride as an acidic medium can be used to synthesize bioplastics. However, the mixture of acetic anhydride, glacial acetic acid, and sulfuric acid was cooled at 7C. Then flax fibers or cotton linters were slowly added with agitation to produce primary cellulose acetate. This cellulose acetate and sulfuric acid were kept for 15h. The resulting fluid was centrifuged, followed by the addition of a plasticizer to the product, which was heated at 60C in the oven and was again diluted with acetone to mould in the desired shape. Anderson and Shenkar[9] and Yang et al.[14] showed the blend of adipic anhydride-plasticized soy protein (Sp. A) with polylactic acid (PLA) at two different concentrations and used it as a sustainable replacement for petroleum plastic in horticulture crop containers. Results indicated that there was a compatible system between Sp. A and PLA in the melt, and Sp. An accelerated biodegradation rate compared to PLA. Before degradation, both the glass transition temperature and melting temperature of the blend containing Sp. A decreased as the concentration of soy protein increased gradually with increasing degradation time. It showed faster biodegradation with the loss of soy component of Sp. A/PLA blends for horticulture crop containers. Furthermore, Tejaswini et al.[4] and Carvalho et al.[6] revealed the significance of biodegradable polymers, which minimize the environmental impact of plastics. Four types of bioplastic were developed based on corn flour with different thicknesses (0.25mm and 0.45mm) with and without natural pine resin. The results showed that bioplastic with 0.25mm and with resin is the one with the highest transparency and greater tensile strength. 0.45mm bioplastic had greater elongation through Fourier-transform infrared spectroscop. It was confirmed that resin provides transparency.

2.2 Experimental Investigations

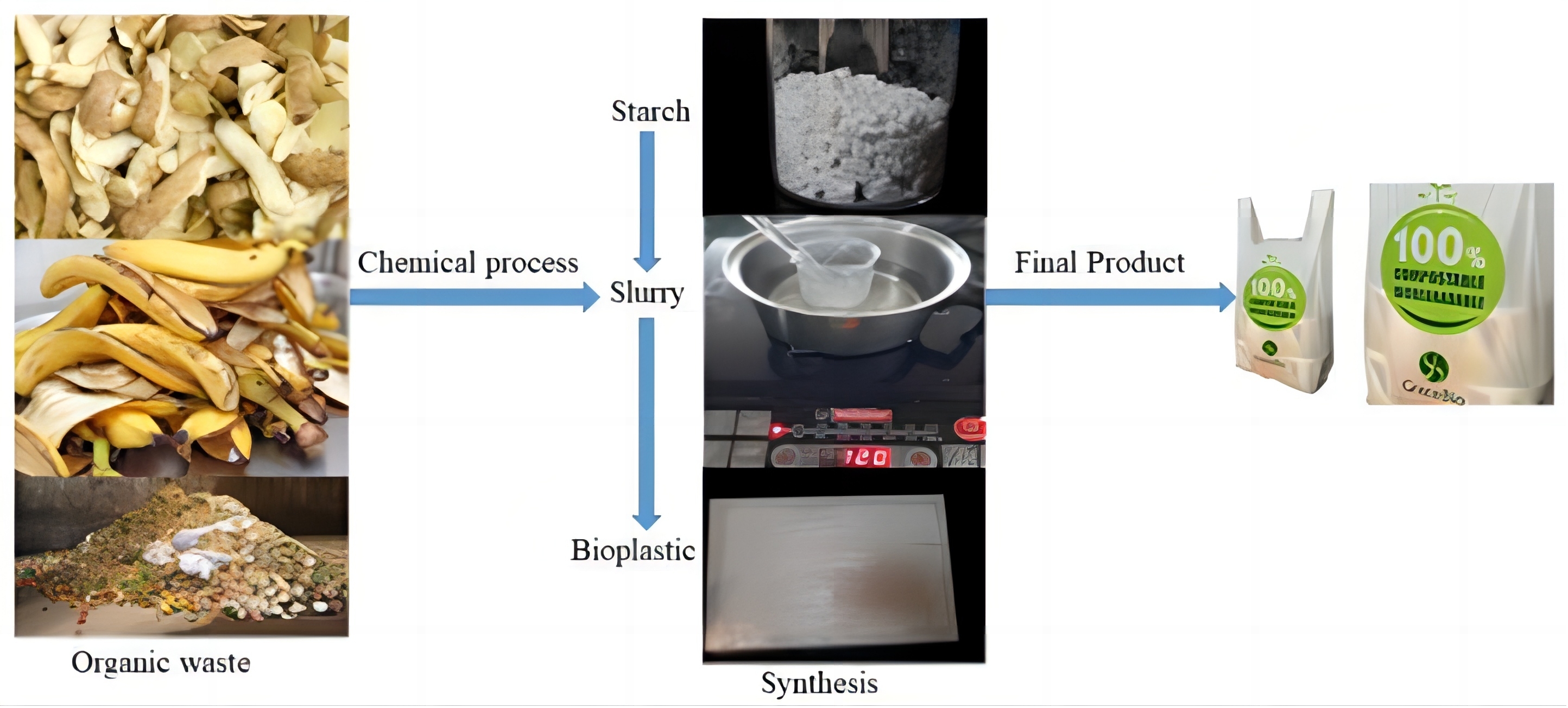

An experimental investigation is carried out using different types of household waste such as potato peels and banana peels, where waste has been finely shredded to obtain a smooth paste. The synthesis process is detailed in Figure 1 where starch was extracted from the finely shredded waste materials. Starch from waste peels of potato and banana were used at a ratio of 1:1. One-third of acetic acid and glycerol was added gradually to make a thick paste of bioplastic at 60C. The paste was slowly spread out on a glass slab uniformly. After 48h of drying, the plastic layer was slowly taken out from the glass slab. Physical and mechanical characteristics (such as thickness, elongation, water and heat resistance, tensile strength) were measured for the synthesized bioplastic.

|

Figure 1. Synthesis of bioplastic.

3 RESULTS AND DISCUSSION

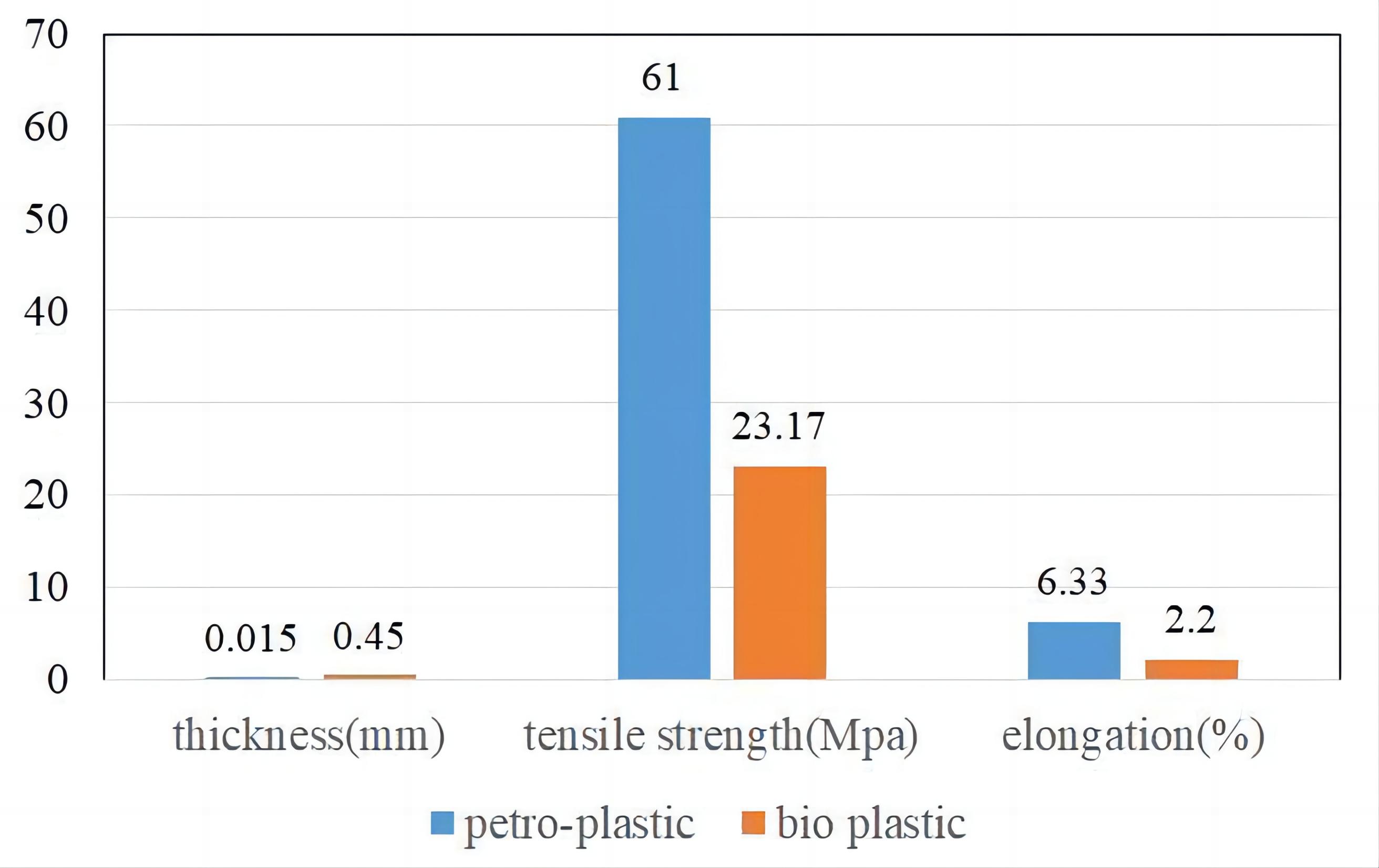

The bioplastic sheet based on potato and banana starch, glycerol, and acetic acid was unmoulded after 48h of air drying. The analyses of bioplastic were done with basic properties such as water and heat resistance. The prepared bioplastics had a low resistance (0.7%) to water and heat. The thickness, tensile strength and elongation were computed and compared with the petroplastic, as shown in Figure 2.

|

Figure 2. Comparison between petroplastic and bioplastic.

It was noticed that the tensile strength of petro plastic is much higher than bioplastic. Also, elongation break is high for petroplastic. This demonstrates that the tensile strength of bioplastic can be increased by mixing different compositions and that though the synthesized bioplastics properties are still not comparable to petroplastics, it shows a significant application in soil mulching. This study can minimize the issues associated with microplastics in the environment[19].

4 CONCLUSION

From this study, it is concluded that the optimized procedure is needed to synthesize bioplastic by using a suitable plasticizer. The starch-based bioplastic has an elongation of 2% and a low resistance to water of 23.7-31.0MPa. Furthermore, successive improvements in the procedure can be made by employing cotton fibers. It increases the efficiency and strength of the bioplastic, though further processing is required to optimize this method. This method has proven to be applicable, and the quality of bioplastic has been improved. Thus, the synthesized bioplastics are suitable for the mulching application.

Acknowledgements

Not applicable.

Conflicts of Interest

The authors declared no conflict of interest.

Author Contribution

Niranjani R and Govani J performed the experiments and written the manuscript under the supervision of Pathak P. Pathak P finalized the manuscript.

Abbreviation List

PLA, Polylactic acid

Sp. A, Soy protein

WG, Wheat gluten

References

[1] Umesh M, Mani VM, Thazeem B et al. Statistical optimization of process parameters for bio plastic (PHA) production by bacillus subtilis NCDC0671 using orange peel-based medium. Iran J Sci Technol A, 2018; 42: 1947-1955. DOI: 10.1007/s40995-017-0457-9

[2] Mai L, Bao LJ, Shi L et al. A review of methods for measuring microplastics in aquatic environment. Environ Sci Pollut R, 2018; 25: 11319-11332. DOI: 10.1007/s11356-018-1692-0

[3] Peng G, Zhu B, Yang D et al. Microplastics in sediments of the Changjiang Estuary, China. Environ Pollut, 2017; 225: 283-290. DOI: 10.1016/j.envpol.2016.12.064

[4] Tejaswini M, Pathak P, Gupta DK. Sustainable approach for valorization of solid wastes as a secondary resource through urban mining. J Environ Manag, 2022; 319: 115727. DOI: 10.1016/j.jenvman.2022.115727

[5] Pujara Y, Pathak P, Sharma A et al. Review on Indian municipal solid waste management practices for reduction of environmental impacts to achieve sustainable development goals. J Environ Manag, 2019; 248: 109238. DOI: 10.1016/j.jenvman.2019.07.009

[6] Carvalho J, Soares M, Castro C et al. Development of bioplastic film for application in the footwear industry. International Conference on Innovation, Engineering and Entrepreneurship, Guimarães, Portugal, 27-29 June, 2018. DOI: 10.1007/978-3-319-91334-6_97

[7] Koller M, Maršálek L, de Sousa Dias MM et al. Producing microbial polyhydroxyalkanoate (PHA) biopolyesters in a sustainable manner. New Biotechnol, 2017; 37: 24-38. DOI: 10.1016/j.nbt.2016.05.001

[8] Nie Z, Wang L, Lin Y et al. Effects of polylactic acid (PLA) and polybutylene adipate-co-terephthalate (PBAT) biodegradable microplastics on the abundance and diversity of denitrifying and anammox bacteria in freshwater sediment. Environ Pollut, 2022; 315: 120343. DOI: 10.1016/j.envpol.2022.120343

[9] Anderson G, Shenkar N. Potential effects of biodegradable single-use items in the sea: Polylactic acid (PLA) and solitary ascidians. Environ Pollut, 2021; 268: 115364. DOI: 10.1016/j.envpol.2020.115364

[10] Ghasemlou M, Daver F, Murdoch BJ et al. Biodegradation of novel bioplastics made of starch, polyhydroxyurethanes and cellulose nanocrystals in soil environment. Sci Total Environ, 2022; 815: 152684. DOI: 10.1016/j.scitotenv.2021.152684

[11] Nilsen-Nygaard J, Fernández EN, Radusin T et al. Current status of biobased and biodegradable food packaging materials: Impact on food quality and effect of innovative processing technologies. Compr Rev Food Sci F, 2021; 20: 1333-1380. DOI: 10.1111/1541-4337.12715

[12] Gonzalez-Gutierrez J, Partal P, Garcia-Morales M et al. Development of highly-transparent protein/starch-based bioplastics. Bioresource Technol, 2010; 101: 2007-2013. DOI: 10.1016/j.biortech.2009.10.025

[13] Vaishnav K, Govani J, Pathak P. Synthesis and characterization of bioplastic for mulch film applications. International Conference on Waste Management, 13-14 February, 2020, Guwahati, India.

[14] Yang S, Madbouly SA, Schrader JA et al. Characterization and biodegradation behavior of bio-based poly (lactic acid) and soy protein blends for sustainable horticultural applications. Green Chem, 2015; 17: 380-393. DOI: 10.1039/C4GC01482K

[15] Shen M, Song B, Zeng G et al. Are biodegradable plastics a promising solution to solve the global plastic pollution? Environ Pollut, 2020; 263: 114469. DOI: 10.1016/j.envpol.2020.114469

[16] Ainali NM, Kalaronis D, Evgenidou E et al. Do poly (lactic acid) microplastics instigate a threat? A perception for their dynamic towards environmental pollution and toxicity. Sci Total Environ, 2022; 832: 155014. DOI: 10.1016/j.scitotenv.2022.155014

[17] Song Y, Zheng Q. Improved tensile strength of glycerol-plasticized gluten bioplastic containing hydrophobic liquids. Bioresource Technol, 2008; 99: 7665-7671. DOI: 10.1016/j.biortech.2008.01.075

[18] Mostafa NA, Farag AA, Abo-dief HM et al. Production of biodegradable plastic from agricultural wastes. Arab J Chem, 2018; 11: 546-553. DOI: 10.1016/j.arabjc.2015.04.008

[19] Ogunola OS, Onada OA, Falaye AE. Mitigation measures to avert the impacts of plastics and microplastics in the marine environment. Environ Sci Pollut R, 2018; 25: 9293-931. DOI: 10.1007/s11356-018-1499-z

Copyright © 2023 The Author(s). This open-access article is licensed under a Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, sharing, adaptation, distribution, and reproduction in any medium, provided the original work is properly cited.

Copyright ©

Copyright ©