Catalytic Conversion of Complex Reactant Systems Makes the World Greener, More Sustainable and Hopeful: Where and How to Go?

Huiru Yang1, Ping Hu1, Zheng Li1, Changwei Hu1*

1Key Laboratory of Green Chemistry and Technology Ministry of Education, College of Chemistry, Sichuan University, Chengdu, Sichuan Province, China

*Correspondence to: Changwei Hu, PhD, Professor, Key Laboratory of Green Chemistry and Technology, Ministry of Education, College of Chemistry, Sichuan University, Chengdu, 610064, Sichuan Province, China; Email: changweihu@scu.edu.cn

DOI: 10.53964/id.2024008

Abstract

Catalysis plays vital roles in chemical industries, which brings out significant convenience to human life in many aspects. With the development of both science and technology, various advanced and multivariate technologies have been cultivated in catalysis. Herein, a brief introduction in the frontiers of catalysis chemistry including single-atom catalysts, single crystal-based model catalysts, molecular switches catalysis and metal-organic frameworks / covalent-organic frameworks based catalysts has been given. Complex reactant systems (Biomass, vehicle exhausted gases, plastic wastes, and waste water) that featured with complex compositions, chemical-bonding and interactions endow researchers huge challenges to convert them to value-added chemicals or treat them to less-toxic or even non-toxic chemicals. Successes on catalytic conversion and degradation of these complex reactant systems sheds light on constructing a greener and more sustainable Earth via using both traditional and advanced catalysts combined with rational strategies. Progresses that achieved on the catalytic degradation of these complex reactant systems have been summarized here. However, the remaining issues concerned with these complex reactant systems drive us to think about how to further deal with them to achieve higher sustainability. Herein, four prospectives are proposed. We truly believe that with the continuous efforts on developing new catalysts with high efficiency and exploring reaction mechanisms under actual conditions towards these complex reactant systems, clearer understanding and better results could be achieved ultimately.

Keywords: catalytic conversion, complex reactant systems, biomass, vehicle exhausted gases, plastic wastes, waste water

1 INTRODUCTION

Since the concept of “catalysis” and “catalyst” was firstly proposed by Berzelius as early as 1835, considerable attentions have been paid to this field[1-3]. At present, the majority of the chemical processes and products closely related to human life is related to catalytic technologies, such as synthesis of ammonia[4], synthesis of sulfuric and nitric acid[5], Fischer-Tropsch process[6,7], petroleum refining including hydrocracking or hydro isomerization[8,9], and polymers production[10,11] etc. Therefore, the development of high-performance catalysts remains an ongoing and essential goal. Aiming to achieve sustainable progresses in catalysis, a multidisciplinary integrated discipline, the developed progress of various technologies and assistance from other fields are inevitably needed. Nowadays, with the rapid development of science and technology, the field of catalysis has evolved from the concept of simply facilitating reactions to proceed into precisely controlling of catalytic reactions or designing catalysts with fine structures or even at atomic level. These improvements and progresses benefit by the development of various reliable and advanced technologies, achieving transformation of the catalytic process from a “black box” reaction into touchable and regulable reaction. Various preparation methods have been developed subsequently. Here, we simply define these catalysts that prepared by simple methods or widely used in industries as traditional ones, and these prepared by more elaborate methods or with fine structure as advanced catalysts. For the preparation of traditional catalysts, methods that are rather easier to operate and more suitable for large production include impregnation, precipitation, comixing, thermal deposition, leaching, melting, electrolytic route, ion exchange and coat etc. have been developed well. Moreover, modifications on catalysts by defect engineering strategies[12] or salt-assisted gas-liquid interfacial element doping[13] etc. have been also explored. Besides, as for the synthesis of advanced catalysts, more elaborate operations and more stringent synthesis conditions are usually required. For example, sol-gel method, microwave ultrasonic method, supercritical technology, physical vapor deposition method, chemical vapor deposition method, solid-phase synthesis and template method, hydrothermal or solvothermal method, micro-emulsion method, electrochemical deposition method, self-assemble and micro-crystallization technologies etc[14,15]. These methods are beneficial for the synthesis of catalysts with fine structure, and the obtained catalysts are featured with specific structural characteristics, morphologies or active sites controllably.

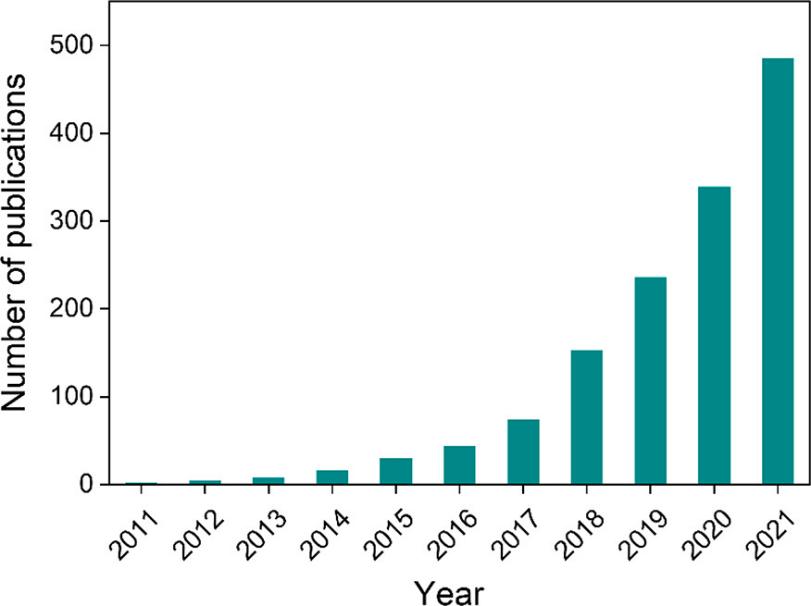

Several new techniques or concepts that stepping into the vision of researchers are proposed here. Single-atom catalysts (SACs) are emerging as one of the research hot-pots recently. Figure 1 displays the number of publications in literature with the word “Single Atom Catalysts/Catalysis” contained in the title of articles since 2011[16], indicating its prosperous development trend. SACs are totally different from traditional nano-catalysts or subnano-catalysts. When metal dispersion reaches 100%, that is, single atoms are produced, various new characters are introduced accordingly, such as sharply increased surface free energy, quantum size effect, unsaturated coordination environment and support-metal interactions. These unique characteristics are significantly different from those of nano or sub-nano particles, vesting SACs superior catalytic performance[17].

|

Figure 1. Number of Publications Where "Single Atom Catalysts/Catalysis" Is in the Title Since 2011. The statistic data are from Web of Science. Reproduced from Ref.[16] with permission from American Chemical Society.

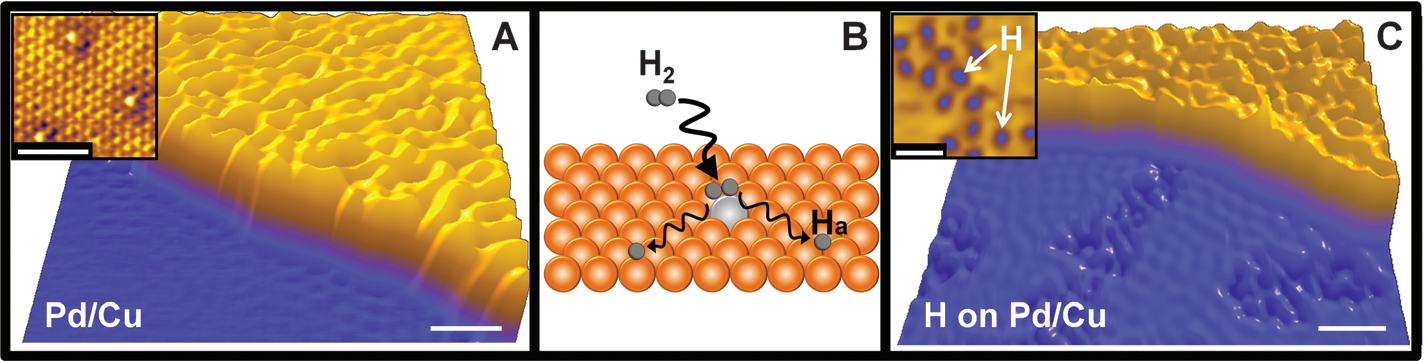

Meanwhile, it can change the adsorption/desorption selectivity to substrates, intermediates or products on the active sites of catalyst, thus affecting the reaction kinetics. Moreover, SACs are typically loaded with low amount of metal, which greatly improves the utilization efficiency of metal atoms. Zhang et al.[18] firstly reported the single-atom Pt1/FeOx catalyst, which showed both excellent stability and high activity for CO oxidation and preferential oxidation of CO in H2. Later, in 2012, Kyriakou et al.[19] achieved the high selectivity towards the hydrogenation of styrene and acetylene by using a SAC where isolated Pd atoms were loaded on the Cu (111) plane. By using means of desorption measurements combining with high-resolution scanning tunneling microscopy (STM), the SACs were characterized clearly, as shown in Figure 2. Meanwhile, theoretical calculation revealed that the isolated Pd atom was capable of lowering the energy barrier to both hydrogen uptake on and subsequent desorption from the Cu metal surface substantially[19]. Besides, employing Fe/SiO2 catalyst where single Fe atoms embedded in a silica matrix, enabled the direct conversion of methane to form ethylene and aromatics exclusively. The absence of adjacent Fe sites in the SACs prevented C-C coupling, further oligomerization, and hence, prohibited coke deposition[20]. The single-atom Pd1/TiO2 catalyst exhibited high catalytic activity in the hydrogenation of C=C bonds, exceeding that of commercial Pd catalysts by a factor of 9, reported by Liu et al[21]. Due to the outstanding and unique catalytic performance of SACs, continuous attentions and deeper researches have been paid to, thus more and more diversified monoatomic catalysts have been prepared, including Pt[22,23], Pd[24,25], Au[26,27], Ir[28], Ag[29], Rh[30], Fe[31,32], Co[33] etc. Nowadays, research interests over SACs are still expanding, and a variety of methods for synthesizing SACs are also being developed. Remarkable achievements have been also obtained by applying these SACs in multiple reactions[16,34-36]. Besides, the applications of MXene-based SACs for energy conversion have also attracted much attentions[37].

|

Figure 2. STM Images Showing Atomically Dispersed Pd Atoms in a Cu(111) Surface and Hydrogen Atoms That Have Dissociated and Spilled over onto the Cu Surface. Reproduced from Ref.[19] with permission from AAAS (Science).

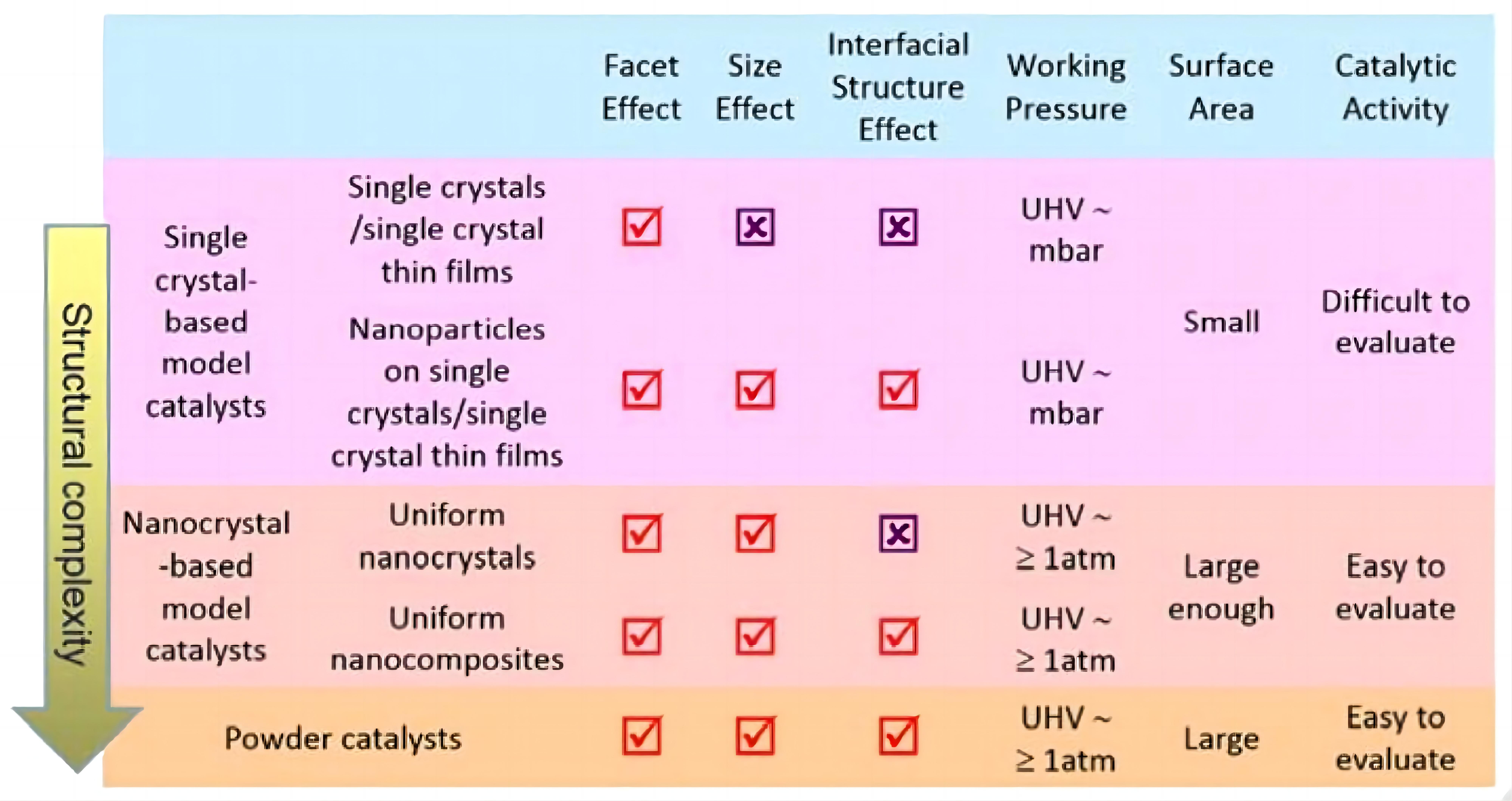

Surface chemistry and catalysis based on single crystals have also gained wide research attentions, realizing the construction of another types of “model catalysts” that active sites are clearly built and demonstrated, thereby a clear activity-relationship can be also easily constructed. Different from nanocrystals, single crystal contributes to synthesize model catalysts with uniform and well-defined surface structures, which is an effective strategy to catalyze simple or precise reactions with deeper explorations on both reactivity and structure-activity relationship. Comparisons between single crystal-based catalysts and nano crystals-based catalysts have been clearly elaborated by Chen et al.[38], as illustrated in Figure 3. Moreover, single crystal-based model catalysts based on single metallic crystal phases have been also developed[39]. Noteworthy, in view of the well-developed and advanced spectroscopic and microscopic techniques, in-situ characterizations of surface structures and active species of single crystal-based catalysts have been easily accomplished[40].

|

Figure 3. Comparisons Between Single Crystal-Based Catalysts and Nano Crystal-Based Catalysts. Reproduced from Ref.[38] with permission from Elsevier.

In recent years, a novel concept “molecular switches” has entered the visions of researchers[41]. Molecular switches are defined as molecules in which bonds, electronic state, or structure change in response to environmental stimuli such as light, heat, electrical field, pH, atmosphere, or pressure[42,43]. They are widely used in photonics, bioscience, chiral synthesis, computer science for logical calculations, DNA sensors and chiral synthesis etc. Based on the ready availability, precise tunability and environment-adjustable properties, the applications of molecular switches in catalytic processes are gradually sieving attentions. Several typical molecular switches catalysis, such as “Redox switches”, “Photo switches”, “pH switches” and “Ligand switches” are introduced here. Hu et al.[44] proposed the Fe-based redox-switches to modulate the catalytic performance of ZSM-5-based catalyst towards the methanol-to-aromatics reaction, which enabled a para-xylene (PX) yield of up to 60% that was 3-6 times higher than previously reported values. Similarly, de Vries and Otten[45] applied this strategy to synthesis a formazanate-Zn catalyst with redox-switching properties, and accomplished the reversible on/off switching of lactide cyclopolymerization. A Ru-catalyzed redox-switchable catalytic system was reported to convert ketone into alcohol, and the catalytic activity of the complex was reversibly switched off and back on again over the course of the hydrogen transfer reaction[46].

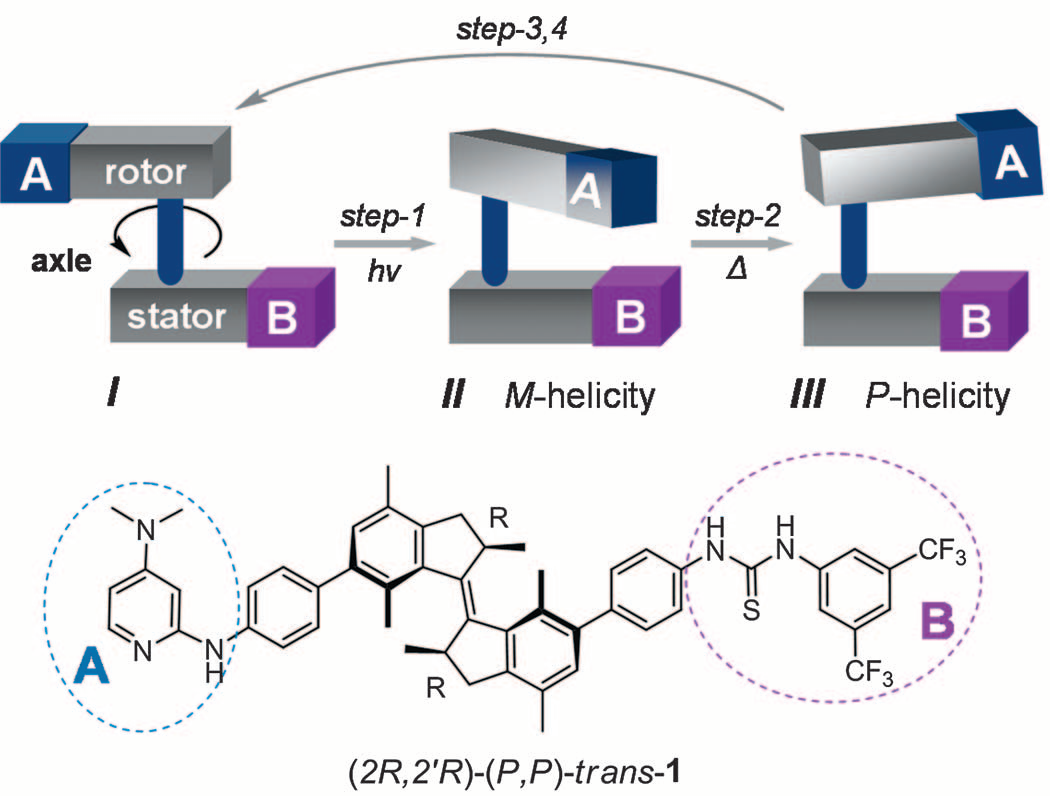

Utilizing light to start or stop the chemical reactions has been studied widely, and molecular photo-switches are chromophores undergoing reversible isomerization between different states upon irradiation with light[47]. These molecular photo-switches find diverse applications as light-stimulated components in various research fields, where the ability to toggle the molecule between distinct states allows reversible control over the investigated systems. In 2011, Wang et al.[48] reported a light-driven molecular motor with integrated catalytic functions in which the stepwise change in configuration during a 360° unidirectional rotary cycle governed the catalyst performance with respect to both activity and absolute stereo-control in an asymmetric transformation. The schematic procedure of this system is proposed in Figure 4.

|

Figure 4. Schematic Illustration of This Integrated Unidirectional Light-Driven Molecular Motor and Bi-Functional Organocatalyst (top) and the Molecular Structure of (2R,2′R)-(P,P)-trans-1 (bottom). Reproduced from Ref.[48] with permission from AAAS (Science).

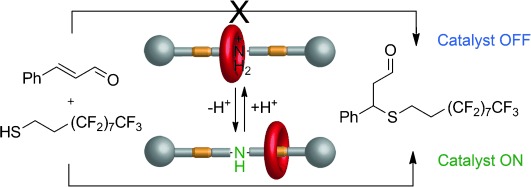

Neilson et al.[49] reported a photo-switchable organocatalysis system wheret light was used to modulate the catalytic activities of N-heterocyclic carbenes, that is, the rates of different reactions were successfully modelled between fast and slow states by alternating exposure to visible or UV light, respectively. The recent booms in the development of photo-switches catalysis indicate that they are valuable tools for the reversible activation/deactivation of different molecules. pH-responsive catalytic systems have also been developed well[50]. In 2008, Balof et al.[51], reported the first pH-responsive catalyst with high and adjustable activity to olefin metathesis which was decorated with dimethylamino groups that were ideal pH-responsive groups. Another switchable organo-catalyst based on a rotaxane architecture had been developed by Blanco et al.[52], which could be switched “on” or “off” by adding acids or bases, acting the role to move the rotaxane ring to either conceal or reveal the catalytic site, as shown in Figure 5. The system could effectively control the reaction rate of Michael addition of an aliphatic thiol to trans-cinnamaldehyde, either by adding the catalyst in its active form or by in situ switching.

|

Figure 5. Diagram of Acid-Base Switching of the Position of the Macrocycle in Rotaxane. Reproduced from Ref.[52] with permission from Wiley.

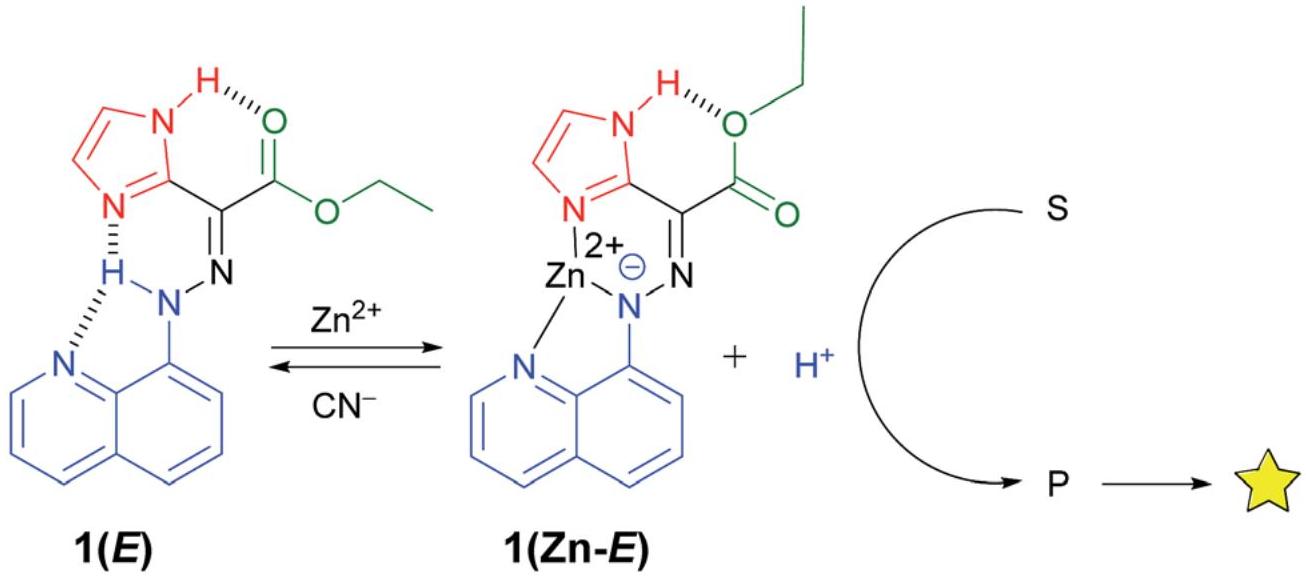

Besides, an elegant molecular switch for the reversible formation of emulsions by simple pH variation was reported by Walace et al.[53] Very recently, Zhang et al.[54] reported the pH-Triggered molecular switch toward texture-regulated Zn Anode. As reported, the periodical fluctuation of H+/OH- was feasible to trigger the pH-dependent molecular switch reaction to modulate Zn/electrolyte interface dynamically, achieving the reversible transformation between γ-butyrolactone and γ-hydroxybutyrate at the Zn/electrolyte interface, and enhancing the reversibility of Zn. Another type of molecular switches such as “Ligand switches” has also been applied to catalysis[55]. The weak-link approach, which builds upon the growing number of methods for preparing metal-containing macrocyclic complexes, allows us to synthesize fine structures through coordination chemistry and hemilabile ligands with transition-metal-based regulatory sites that can be modulated through ligand displacement reactions. In this manner, catalytic processes can be turned on or off depending upon the presence or absence of small molecules or elemental anion effectors, as called “Ligand switches”[56]. Foy et al.[57] developed coordination-coupled deprotonation (CCD) driven signaling and signal enhancement sequences by using the zinc(II)-initiated CCD of a hydrazone switch to instigate an acid catalyzed imine bond hydrolysis that separated a quencher from fluorophores, thus leading to emission amplification. Figure 6 disclosed the working procedure of this system. Similar hydrazone switches had been also proposed by Pramanik and Aprahamian[58], and later applied for sequestering zinc(II) from the environment.

|

Figure 6. The Imidazolyl-Containing Switch 1(E) Underwent CCD upon Addition of Zinc(II) Resulting in the Release of a Proton to the Environment. The Acidification of the Solution Can Be Used to Turn “On” pH-Sensitive Dyes (S/P), Leading to Fluorescence Output. Reproduced from Ref.[57] from the Royal Society of Chemistry.

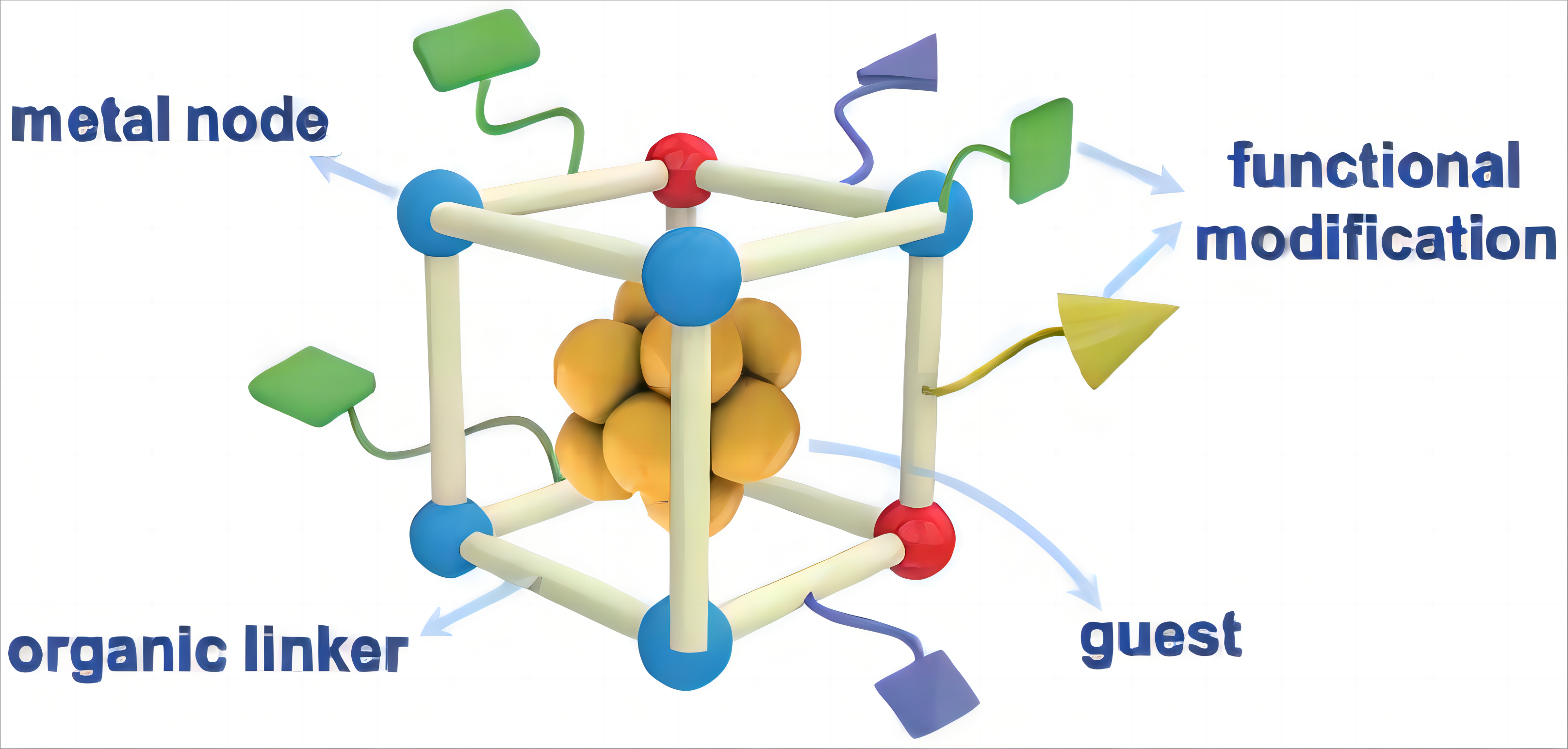

In addition to the SACs, molecular-switch catalysis mentioned above, the applications of metal-organic frameworks (MOFs) and covalent-organic frameworks (COFs) materials in catalysis are also blooming, since they were firstly used as catalysts in 2000 and 2011, respectively[59]. MOF, a rapidly developing interdisciplinary novel material, attracts extensive interests in catalysis since it is a relatively new class of crystalline porous materials with high surface area, structural diversity, and tailorability[60]. In general, there were three parts of MOFs that could be utilized as active sites for catalytic process including metal nodes, organic linkers and pore space, which was clearly presented in Figure 7[61].

|

Mature and diverse approaches to synthesize MOFs, such as solution impregnation, double-solvent approach, chemical vapor deposition, solid grinding, thermal decomposition and so forth have been well developed[62]. Accurate control over the microenvironment of catalytic sites in MOFs that dominating the molecular/electron-transfer process and regulating the intrinsic activity of catalytic sites have got deeper and precise investigations[63]. Furthermore, these materials also exhibit superior catalytic performance in a variety of reactions such as electrochemical water splitting[64], treatments of waste water[65], electrocatalytic/photocatalytic CO2 reductions[66,67], hydrogen/oxygen evolution reactions[68], oxygen reduction reactions, nitrogen reduction reactions[69], CO2 selective hydrogenation[70], photocatalytic hydrogen peroxide production[71], and photocatalytic nitrogen fixation etc[72]. Meanwhile, graphene/MOFs composites are also widely used in energy and environmental protection fields, which have been reviewed by Nazir et al[73]. Furthermore, by means of decorations, MOFs derivatives have attracted widespread attentions due to their outstanding merits like large specific surface area, tunable porosity, unsaturated active sites inherited from MOFs precursors and higher water/thermal stability. Hence, they are further widely applied in catalyzing the removal of pollutants from water[74,75]. The advantages of using MOFs as catalysts, such as high metal-atom utilization efficiency, high reactivity, high selectivity and stable reusability etc. stimulate researchers to contribute more efforts in this field. The other kind of new material, COFs, is also acting as star in catalysis field due to adjustable porosities, high thermal and chemical stabilities, tunable functionalities and flexibility in installing catalytic active sites[76-79]. COFs are a class of crystalline porous polymers allowing for atomically precise integration of organic building units to create order skeletons and nanopores in the repetitive manner[77,80]. Based on the structure characteristics of COFs, three synthetic methodologies to construct COF-based catalysts have been systematically developed and further well elaborated, which can be simply summarized as in-situ synthesis, bottom-up synthesis and post-synthetic approaches[76]. Furthermore, COFs can be constructed into either two-dimensional or three-dimensional porous networks depending on their building block dimensions[79,81]. Currently, the post-synthetic modifications of COFs are introduced, such as (1) incorporation of a variety of active metal species by using metal complexation through coordination chemistry, (2) covalent bond formation between existing pendant groups and incoming constituents and (3) chemical conversion of linkages, so that both unique structure features and reactivity can be obtained[82]. Applications of COFs in the field of thermal catalysis, photocatalysis and electrocatalysis including organic coupling reactions, oxidation-reduction reactions, addition reactions, degradation/conversion reactions and so on have been all widely explored and investigated[83,84].

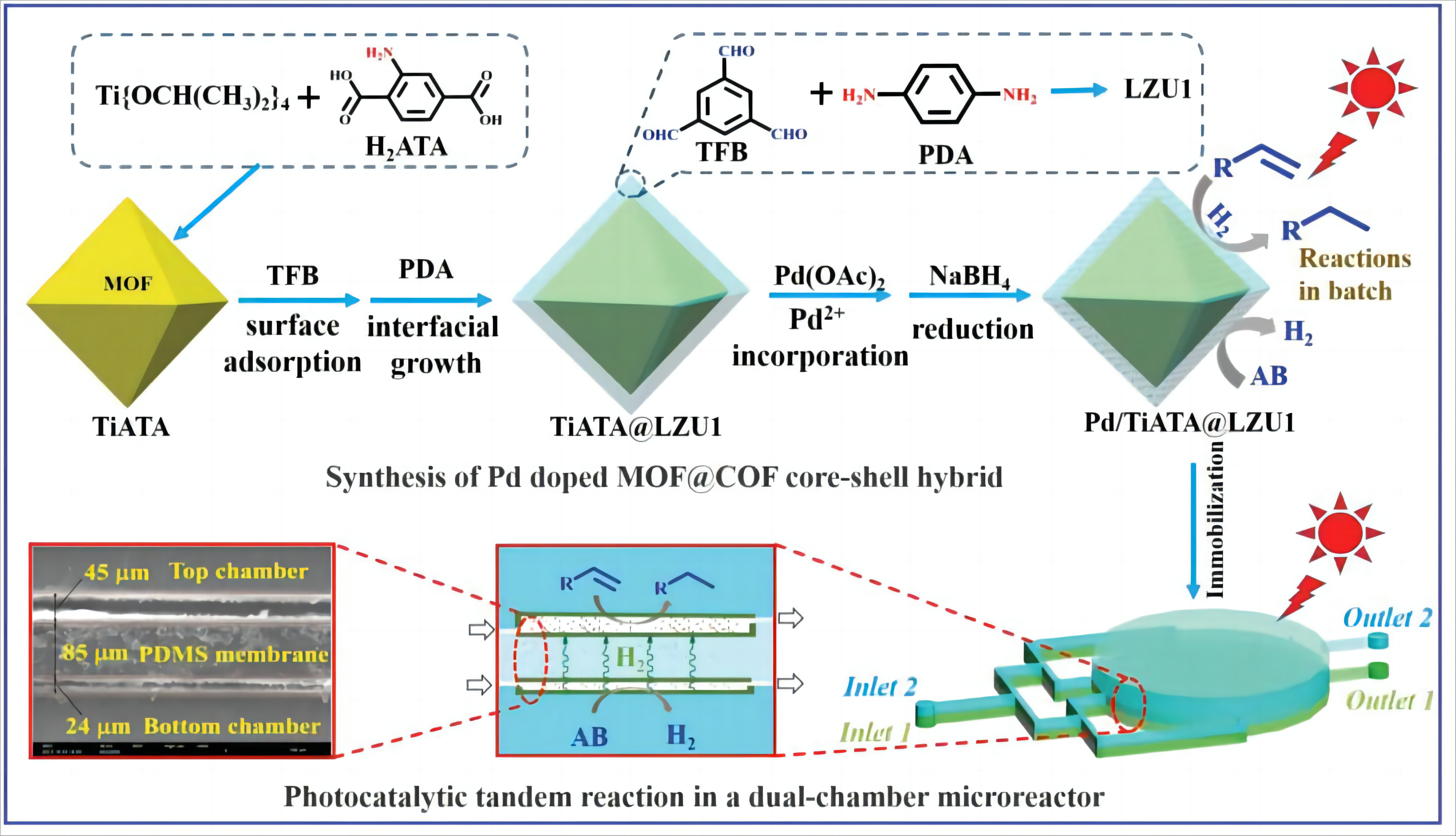

According to their structures and compositions, COF-based catalysts are classified as COFs with reactive skeletons, with reactive pendant groups and with reactive metals[76]. Compared with the well-developed MOFs and/or COFs-based catalysts, the development of MOF/COF composite-based catalysts merely starts[85]. These composites include MOF/COF hybrids, including MOF@COF and COF@MOF with core-shell structure, MOF + COF, C-MOF, and COF-in-MOF. Integration of MOFs and COFs is an effective strategy to construct new types of catalysts[86]. A detailed description for synthesizing a Pd doped MOF@COF core-shell material was presented in Figure 8, reported by Sun et al[87].

|

Figure 8. Schematic Scope of the Preparation of Pd Doped MOF@COF Core-Shell Material. Reproduced from Ref.[87] with permission from Wiley.

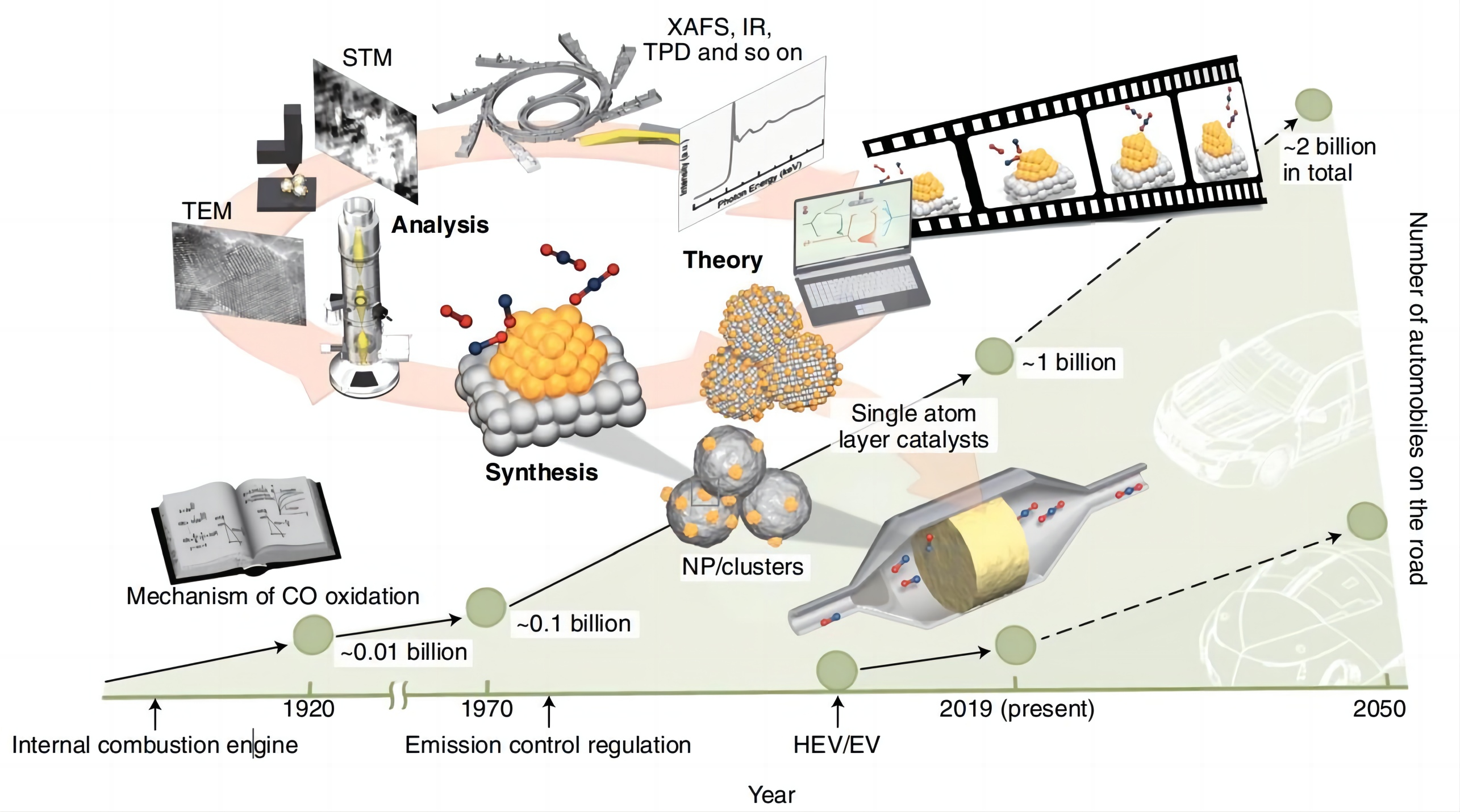

Despite model catalysts that with precisely controlled active sites we commented above, a great deal of model reactions, such as CO oxidation, NH3 synthesis/deposition, and H2O deposition etc. have been also studied extensively, and much dazzling achievements have been made. As for the CO oxidation reaction, various catalysts including noble-metal based catalysts such as Pt, Au and Pd[88,89], non-noble metal catalysts[90] have been synthesized successfully wherein efforts towards fulfilling high-catalytic performance via chemical-tuning strategies, in which the size, structure, shape and degree of alloys are controlled to alter the electronic structure, catalyst-oxide support interactions and resulting interactions between adsorbates and the catalyst etc[91]. Furthermore, detailed CO oxidation pathways over typical catalysts with different structural characteristics such as single atoms, nanoclusters or nanoparticles have been clearly elaborated[92,93] . Meanwhile, active species were also clarified[94,95]. Beniya et al.[91] had reviewed the progresses that achieved on CO oxidation reactions catalyzed by SACs, and then addressed the necessity of the development of low-cost, environment-friendly automotive catalysts, as shown in Figure 9.

|

Figure 9. Necessity of the Development of Low-Cost, Environment-Friendly Automotive Catalysts. Reproduced from Ref.[91] with permission from Springer.

Likewise, systemic investigations on the NH3 synthesis/deposition reactions[96,97] and H2O deposition reactions[98,99] have been conducted. In summary, in-depth systematic explorations on both model catalysts as well as model reactions are highly effective in establishing surface structure-activity relations and identifying active sites. To achieve these goals, a prerequisite is to fabricate a series of model catalysts with uniform and well-defined surface structures varying around specific structural parameters. Meanwhile, selecting model reactions that comprised of simple components as probe reactions provides possibilities to clarify real reaction mechanism.

To date, much efforts have been devoted to these field of catalysis, and remarkable achievements have been obtained accordingly, which is of great importance to improve the quality of human life. Therefore, lights have been shed on the conversion and utilization of complex reactant systems where compositions, chemical bonding and interactions are highly complicated due to the vigorous development of catalysis. Totally different from the simple systems that comprises of only single component, the complex reactant systems such as biomass (cellulose, hemicellulose, lignin, and chitin), vehicle exhausted gases, wasted plastics and waste water etc. have rather complexed compositions. Therefore, the catalytic conversion or degradation of these complex reactant systems not only faces the challenges that the applied catalytic systems should be effective for multiple components, but also encounters the obstacles that large quantities of pollutants or impurities included in these systems would lead to the poisoning or deactivation of catalysts. Accordingly, long-term sustainable developments would be highly restricted due to these reasons. Aiming to address these issues, using smart conversion strategies as well as rational protocols and powerful toolkits such as precisely designed catalysts with finely tuned active sites can devote to accomplish this goal. Finally, the full valorization or well disposal of these complexes could be achieved. Meanwhile, the newly developed analytic methods and advanced characterization techniques with high accuracy help to clarify the actual reaction mechanisms and guide the design of catalysts.

2 CATALYTIC CONVERSION OF COMPLEX REACTANT SYSTEMS

2.1 The Catalytic Conversion of Biomass

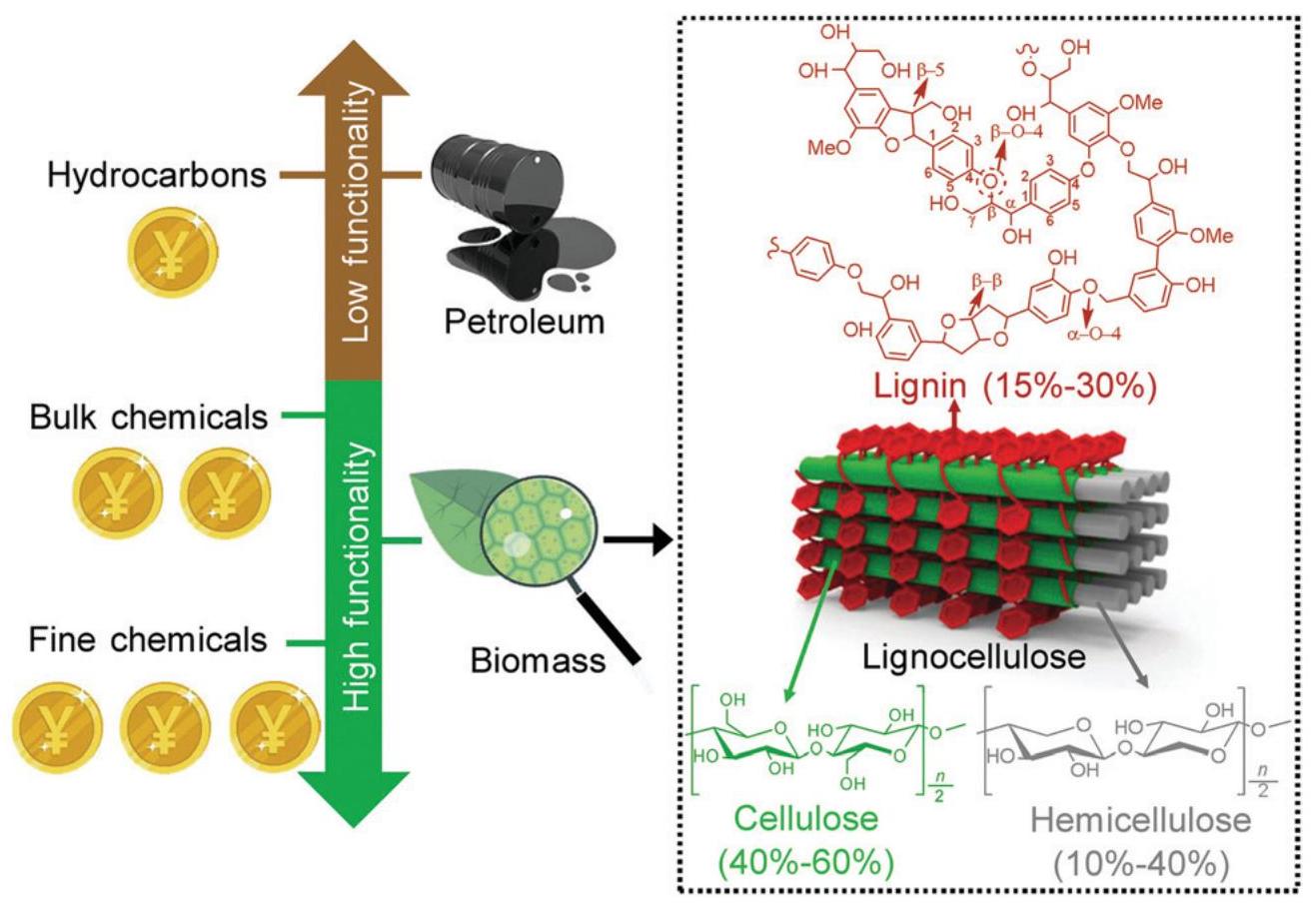

Biomass refers to a wide range of natural organic materials, either plant-based or animal-based, that is a potential resource for producing chemicals and fuels. Among various renewable resources (e.g., solar energy and wind, etc.), biomass is the only one containing C, H, N and O elements, which endows it unique merits in producing value-added chemicals (hydrocarbon, bulk and fine chemicals) directly, as shown in Figure 10[100-102]. Thereby, the exploitation of biomass conversions offers great potential for sustainable chemical supplies, as an alternative to current fossil fuel based chemical manufacturing industries[101,103]. A shift to renewable biomass would not only reduce the dependence on fossil fuels, but also alleviate the environment-pollution concerns about excessive green-house gases emissions, which are both beneficial for building a greener Earth[104]. Here, we mainly focus on the conversion of lignocellulose and chitin. The major components of lignocellulose include lignin, cellulose, and hemicellulose. All of them are comprised of numerous units and connected by complex chemical bonds. For instance, lignin, is a complex polymer consisting of various methoxylated phenylpropanoid units[105]. Selective scission of the crosslinked C-C/C-O bonds would produce aromatic products, such as benzaldehydes and phenols[106].

|

Figure 10. Utilization of Biomass for Production of Hydrocarbons, Bulk and Fine Chemicals. Chemical Structures of Major Components (Lignin, Cellulose and Hemicellulose) of Lignocellulosic Biomass. Reproduced from Ref.[102] with permission from The Royal Society of Chemistry.

As for cellulose, it is intrinsically recalcitrant owing to the abundant intra- and inter-molecular hydrogen bonds protecting the β-1,4-glycosidic bonds from attack by foreign molecule, which renders it difficult to be converted[107]. Furthermore, its insolubility in most solvents aggravates the difficulty for transformation. Only with concentrated mineral acids or supercritical liquids can cellulose be depolymerized to a substantial degree, and subsequence reactions can be proceeded. Hemicellulose with amorphous structure is composed of long chains with a variety of pentoses and hexoses, and is therefore easier to be degraded than cellulose, but is also with high difficulty[108]. Chitin is a linear polymer, and the second most abundant natural biopolymer on Earth (after cellulose), which is widely distributed in plankton and the exoskeletons of insects and crustaceans, and organisms. About 100 billion tons of chitin are generated per year[109]. Similar to other biomass mentioned above, the compositions and chemical-bonding in chitin are also highly complex, mainly comprised of N-acetyl glucosamine linking by β-(1→4) bonds. One point should be noted is that chitin contains natural nitrogen, which is totally different from lignocellulose biomass. Therefore, it is of great significance to make full use of the N element in chitin to prepare nitrogen-containing chemicals[110]. In order to achieve the catalytic conversion of biomass to produce value-added chemicals, the design of catalytic systems with high and tunable performance that can selectively cleave crosslinks in biomass and activate the target chemical bonds is highly pursued.

2.1.1 The Catalytic Conversion of Lignocellulose

2.1.1.1 The Catalytic Conversion of Cellulose into 5-Hydroxylmethylfurfural (5-HMF) and Levulinic Acid (LA)

Lignocellulosic biomass is consisted of cellulose (30-50 wt%), hemicellulose (20-40 wt%), lignin (10-20 wt%), extractives, and ash etc.[111], and its reserves in nature are abundant. Cellulose is a linear biopolymer of glucose units linked by β-1,4-glycosidic bond, where complicated inter/intramolecular hydrogen bonds (H-Bonds) network between hydroxyl group in cellulose was formed and robust crystal structures were produced accordingly[112]. 5-HMF as well as LA were both listed as important platform chemicals by U.S. energy department[113] since they can be converted into lots of bio-based fuels and value-added chemicals, which provides a desired alternative for fossil fuels-based products[114,115]. The conversion of cellulose into value-added chemicals is promising, and much works have been conducted. For the reaction networks from cellulose to 5-HMF/LA/FA, cellulose was firstly hydrolyzed into glucose, which was then isomerized into fructose, and 5-HMF was obtained from fructose via dehydration, and LA was produced via rehydration of 5-HMF[116,117]. Therefore, upgrading cellulose into 5-HMF/LA was significantly crucial for biorefinery of lignocellulosic biomass.

Recalcitrant structure of cellulose is one of the challenges for the conversion of cellulose to 5-HMF/LA due to its insolubility in most solvent, which leads to extremely limited accessibility for solvent molecules and catalysts[118]. Meanwhile, another problem for cellulose-to-5-HMF/LA conversion is repolymerization of reactive intermediates and products (i.e., 5-HMF and LA), giving much biomass-derived carbon loss and decreasing the selectivity and yield of 5-HMF/LA[119]. Therefore, the design and adjustment of catalytic systems rationally are of great concern for cascade reactions of cellulose to 5-HMF/LA. For tandem conversion of cellulose to 5-HMF/LA, both depolymerization of cellulose into glucose and isomerization of glucose to fructose are the determining step with activation energy of 113.0-180.0KJ·mol-1[120] and 59.0-103KJ·mol-1[121], respectively. Therefore, homogeneous, heterogeneous or phase-transition catalysts with appropriate Lewis acidity and/or Brønsted acidity could ensure catalytic performance well for converting cellulose to produce 5-HMF/LA.

2.1.1.1.1 Homogeneous Catalysts

Mineral acids such as HCl and H2SO4 were widely chosen as catalysts for cellulose-to-LA conversion, giving moderate yields of LA. Girisuta et al.[122] reported 1M H2SO4-catalyzed ‘one-pot’ conversion of cellulose with loading of 1.7 wt.% to LA with yield of 60.0mol% in water at 423K for 2.0h. While lowering the concentration of H2SO4 to 0.5M and 0.1M, the yield of LA was both decreased due to slow depolymerization of cellulose. In KCl-saturated aqueous solution, Qin et al.[123] obtained high LA yield of 67.3mol% from 10.0 wt.% cellulose catalyzed by H3PO4 at 453K for 1.0h. Furthermore, Hu et al.[124] reported an efficient catalytic system for the conversion of cellulose or lignocellulosic biomass-fractionated cellulose with high loading of 15.0 wt.% to high-yield LA of 60.8mol% and 80.1mol% catalyzed by benzenesulfonic acid in 2-methyltetrahydrofuran and water (VMTHF/VH2O = 2/1) biphasic solvent, respectively. Ionic liquids (ILs) bearing sulfonic groups or HSO4- anion show good dissolving capacity of cellulose via forming competing H-Bonds of ILs with hydroxyl group of cellulose[125] and behaved well for catalytic conversion of cellulose to LA. Due to the lack of Lewis acidity, Brønsted acid-catalyzed HMF formation from cellulose showed low catalytic activity[126,127]. Compared with Brønsted acids, metal salts or bifunctional acid-base organic catalysts exhibited excellent catalytic performance for HMF/LA formation from cellulose due to Lewis acid or Brønsted base-catalyzed rapid glucose-to fructose isomerization and dehydration of fructose. It has been reported that metal species such as [Cr(OH)2(H2O)4]+[128] and [Al(OH)2(H2O)4]+[129] could coordinate with glucose helping the isomerization of glucose to fructose via 1,2-H transfer[130] , followed by rapid dehydration of fructose to 5-HMF and rehydration of 5-HMF to LA catalyzed by Brønsted acid due to its lower activation energy. In γ-valerolactone (GVL) and water (VGVL/VH2O = 17/3) mixed solvent, a high LA yield of 88.5 mol% was obtained from 1.5 wt.% cellulose catalyzed by heteropolyacid H3PW12O40 with bifunctional Lewis and Brønsted acidity at 468K for 2.0h[131]. Compared with LA, 5-HMF was more unstable and was ready to repolymerization, especially at high reaction temperature. Hence, bifunctional Lewis and Brønsted catalysts combined with organic and water mixed/biphasic solvent was a better choice for the conversion of cellulose to 5-HMF. Gong et al.[132] used the prepared cellulose formate as the substrate for the synthesis of 5-HMF catalyzed by 0.1M AlCl3 and 0.05M HCl in dimethyl sulfoxide (DMSO) and water (VDMSO/VH2O = 4/1) mixed solvent at 423K for 0.5h, yielding 67.3 mol% 5-HMF. Shi et al.[133] reported Al2(SO4)3-catalyzed conversion of high-loading cellulose of 33.0 wt.% to 5-HMF with the yield of 71.2 mol% in tetrahydrofuran-cyclohexane (THF) and water biphasic solvent (VTHF-CHX/VH2O = 19/3) at 453K for 1.0h.

Homogeneous catalyst-catalyzed conversion of cellulose to 5-HMF/LA showed high catalytic activity due to easily controllable Lewis and Brønsted acidity with the help of solvent. However, stabilization of intermediate and products from cellulose deserve further considerations for its rapid repolymerization catalyzed by homogeneous catalyst.

2.1.1.1.2 Heterogeneous Catalysts

Lots of heterogeneous catalysts such as metal oxides, zeolites, metal phosphates, carbon materials, and organic materials was prepared for the conversion of cellulose to 5-HMF/LA due to its recyclability and adjustable Lewis/Brønsted acidic sites compared to homogeneous ones. Potvin et al.[134] utilized ion exchange resin as solid acid catalysts to catalyze the depolymerization of cellulose and further conversion of glucose to 72.0 mol% LA in NaCl-saturated aqueous solution at 463-473K for 5.0d. Ding et al.[135] reported the Al-modified NbOPO4 as catalyst for synthesis of LA from 5.0 wt.% cellulose in water at 453K for 24h, obtaining 52.9 mol% LA. Due to limited contact between cellulose and solid catalysts, the catalytic performance of heterogeneous catalysts behaved not well for depolymerization of cellulose. Yu et al.[136] prepared a hyperbranched poly(arylene oxindole)s organic material grafting by -Cl and -SO3H groups (5-Cl-SHPAO) with -Cl groups interacting with hydroxyl groups of cellulose, which catalyzed the conversion of cellulose to LA with the yield of 48.0 mol% in water at 438K for 5.0h.

For cellulose-to-5-HMF, metal oxides, metal phosphates, and zeolites bearing both Lewis and Brønsted acidic sites catch the fancy of 5-HMF synthesis from cellulose. Atanda et al.[137] modified TiO2 with phosphate group to get functionalized surface that with both Lewis and Brønsted acidity. Ball-milling cellulose was converted to 5-HMF with high yield of 86.2 mol% catalyzed by P-TiO2 in THF-NMP/NaCl-saturated aqueous biphasic solvent (VTHF-NMP/VH2O=4/1) at 453K for 105min. Cao et al.[138] designed the hafnium phosphate catalyst with various ratio of Hf/P, which could endow this catalyst with different Lewis/Brønsted acid densities, where 69.8 mol% 5-HMF was yielded from 2.0 wt.% cellulose catalyzed by (HfO)(PO4)2 in THF/NaCl-saturated aqueous biphasic solvent at 463K for 4.0h. To increase the contact between catalysts and cellulose, choline ion-functionalized HY zeolites was utilized to catalyze the conversion of cellulose to 5-HMF, giving 55.0 mol% 5-HMF in methyl isobutyl ketone and NaCl-saturated aqueous biphasic solvent (VMIBK/VH2O=3/1) at 453K for 3.0h[139].

Although heterogeneous catalysts showed excellent performance for cellulose-to-5-HMF/LA conversion, these catalytic systems still suffered from high reaction temperature and long reaction time, massive usage of organic solvent, and equipment-corrosive NaCl, due to limited solid-solid contact between catalysts and cellulose.

2.1.1.1.3 Phase-transition Catalysts

Phase-transition catalysts possess the advantages of both homogeneous and heterogeneous, overcoming the difficult recovery of liquid acid and restricted contact of solid acid. Zhang et al.[140,141] prepared choline-modified heteropoly-acid via facile ion-exchange, which was insoluble at room temperature and soluble at reaction temperature in water. High yield of 5-HMF and LA over 70.0 mol% could be obtained from cellulose at low reaction temperature below 413K. However, losses of catalysts appeared during the recovery of catalysts via recrystallization.

Compared to other types of catalysts, phase-transition catalysts are more desirable. In summary, these catalytic systems made great progresses for conversion of cellulose to 5-HMF/LA. Rational design of catalysts should be considered, including: 1) increasing the interaction of catalysts with cellulose via decorating the surface property of catalysts or solvent effects; 2) controlling the cascade reaction rate of depolymerization, isomerization, dehydration via functionalizing appropriate Lewis and/or Brønsted acidity; 3) decreasing the accessibility of products for catalysts; and 4) recycling of catalysts.

2.1.1.2 The Catalytic Conversion of Lignocellulose to GVL

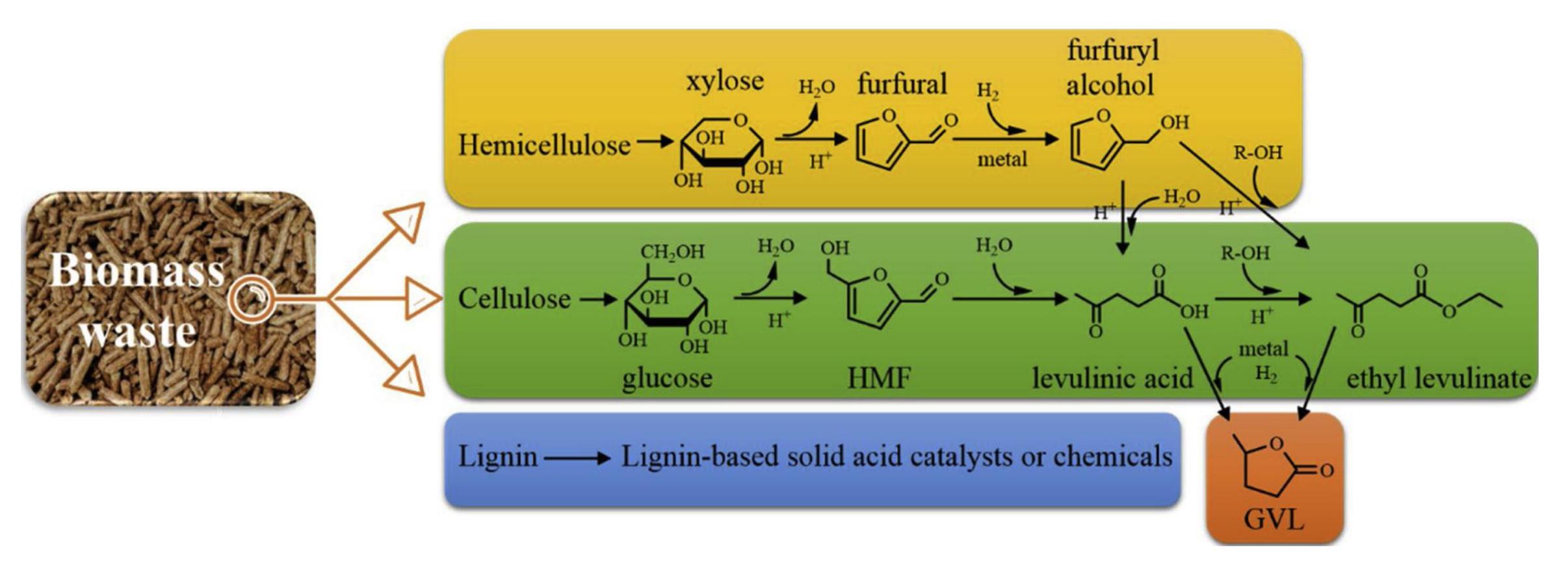

GVL, which is accessible from renewable lignocellulosic biomass, has been identified as one of the most promising platforms for the sustainable production of fuels and value-added chemicals[142,143]. As shown in Figure 11, the reactions of lignocellulose to produce GVL are summarized, which can be performed through two paths. In the first path, cellulose is hydrolyzed to glucose and then isomerized to fructose, followed by further dehydration to form 5-HMF, which would be decomposed to form LA or levulinate. Finally, a hydrogenation-cyclization cascade reaction transforms both LA and levulinate into GVL[144,145]. In the other transforming path, hemicellulose, is firstly hydrolyzed to xylose. Later, it transforms to FAL, FAL alcohol and LA subsequently through continuous dehydration reactions. Finally, LA undergoes hydrogenation process to produce GVL. Therefore, it is very clear that the reaction networks for producing GVL from biomass is highly complicated, and LA is one of the indispensable intermediates. To accomplish the goal for producing GVL from biomass directly, demands on rational design of catalysts and precisely control of desired reactions should be meet.

Actually, researches focused on the formation of GVL from LA have been widely reported[146,147], which lays solid foundation for the conversion of biomass to produce GVL. However, compared to pure LA, direct utilization of raw biomass as feedstock for GVL production is more cost-effective, because of the elimination of biomass pretreatment and the accomplishment of minimal processing steps[148]. In General, an integrated approach, relative to one-pot multi-step process, is widely adopted when producing GVL from biomass. Wherein, an acidic catalyst is employed to catalyze several consecutive reactions to yield LA, which is further upgraded to GVL with the assistance of metal catalyst.

|

Figure 11. Reactions for Producing GVL from Hemicellulose and Cellulose in Lignocellulosic Biomass. Reproduced from Ref.[144] with permission from Elsevier.

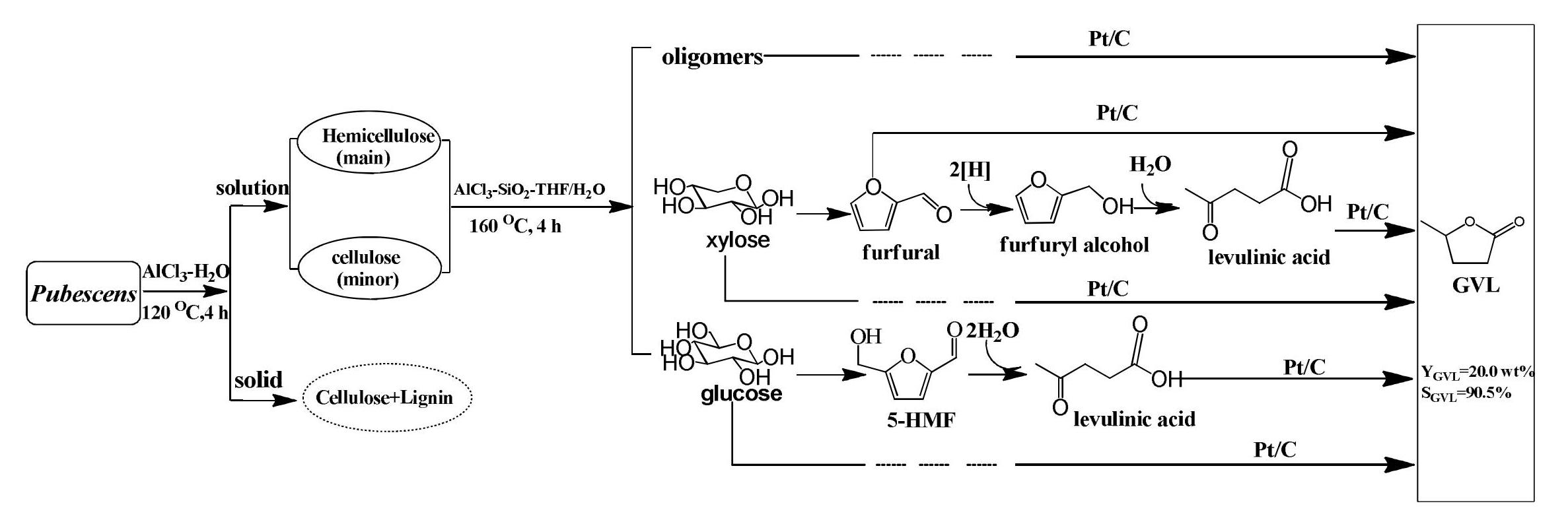

Galletti et al.[149] reported the straight production of GVL directly from water slurries of giant reed by adopting bifunctional (acid and hydrogenating) catalytic systems based on Ru/C and NbO or NbOPO4. Mild reaction conditions (0.5MPa of hydrogen and 70℃) were possible for the hydrogenation step. GVL yield up to 16.6 wt.% calculated from the starting weight of dry biomass was reached, with an almost complete and selective conversion of the intermediate LA. Later, Ding et al.[135] realized the direct catalytic conversion of cellulose to GVL through sequential reactions that LA was firstly formed by using niobium-based solid acids with aluminum modified (Al-NbOPO4), and LA was further upgraded to GVL on a commercial Ru/C catalyst. It was found that the doping of Al enhanced the intensities of Lewis and Brønsted acids, especially the strong Lewis acid, thus resulting in the increase of LA yield from cellulose. Finally, a higher GVL yield from cellulose was achieved. Another integration that combined a highly cross-linked ionic liquid polymer (PDVB-IL) and Co/TiO2 to catalyze the degradation of cellulose was reported, and this catalytic system gave an overall GVL yield of 55%[150]. A combination of H3PW12O40 with Ru/TiO2 catalyst was also proved to be effective for GVL production from inulin with 70.5% yield. Cao and colleagues obtained a GVL yield in a range of 57% (from sucrose), 50% (from starch) and 33% (from cellulose) over H2SO4 and Au/ZrO2-VS catalyst[151]. A cheap Cu-based catalyst Cu/ZrO2-OG, cultivated by the same group also showed good catalytic performance for the conversion of giant reed through the one-pot process, and the yield of GVL decreased to 18.5% (based on the weight of dry biomass)[152]. A three-step method had been developed for the selective conversion of hemicellulose in pubescens to GVL by Pt/C catalysts without the addition of external hydrogen, reported by Luo et al[153]. A high yield of 20.0% GVL based on the weight of pubescens with a high selectivity of 90.5% was achieved. The reaction procedure was shown in Figure 12. By well characterizations, platinum species were found to interact with the carboxylic and lactonic groups of activated carbon, and the Pt (220) surface might exhibit high activity for the conversion of LA and formic acid (FA) to GVL. Besides, the Pt/C catalyst was effective for the in-situ generation of hydrogen due to the high selectivity towards the decomposition of FA.

|

Figure 12. The Origin of GVL from an Aqueous Mixture Derived from Hemicellulose in Pubescens. Reproduced from Ref.[153] with permission from the Royal Society of Chemistry.

Later, the same group developed a two-step integrated strategy for GVL production from FAL residue. Wherein, LA and FA were produced from furfural (FAL) residue using SnCl4 as a catalyst in the first step, and the obtained products were subsequently employed as feedstock for GVL production by a developed bimetallic Au-Ni/ZrO2 catalyst in the second step[154]. This work also gave a potential strategy for producing GVL directly from raw lignocellulosic biomass without external H2. Characterizations revealed that the loading of Ni promoted the reduction of Auδ+ to Au0, and facilitated Au0 dispersion with less aggregation, which improved the hydrogenation ability of this catalyst.

2.1.1.3 The Catalytic Conversion of Lignocellulose to FAL and Other Chemicals

Except the above-mentioned chemicals produced from biomass via catalytic degradation, other types of chemicals can be also obtained[155]. FAL, another type of important chemical, is mainly produced from hemicellulose. Both homogeneous and heterogeneous catalysts were adapted. For example, Zhang et al.[156] reported the preparation of FAL from pine wood with 33.6% yield by AlCl36H2O with the assistant of ionic liquid (1-butyl-3-methylimidazolium chloride). Besides, thiourea could also promote the yield of FAL from empty fruit bunch by using H2SO4 as catalysts, and the corresponding yields increased from 33. 8% to 61.0%[157]. Effective heterogeneous catalysts towards the catalytic degradation of hemicellulose to FAL had been also reported, such as WO3/SiO2 and Ga2O3/SiO2[158], zeolite SAPO-34[159], ZSM-5[160] etc., and the resultant FAL yields varied from 55-67%. By rationally designing a two-phase solvent system (GVL/water), the yields of FAL from corn stover and Eucalyptus sawdust catalyzed by SAPO-18[161] and H-SAPO-34[162] increased significantly to 95% and 99%, respectively. For the production of other value-added chemicals, Wang et al.[107] used 2%Ni-30%W2C/AC catalyst to convert cellulose to ethylene glycol (EG) via a hydrolytic hydrogenolysis method successfully at 503-523K and 6-10MPa H2, achieving 73.0% yield of EG . However, when applying this catalyst to convert birch wood, without any pretreatment, EG yield reduced sharply to 38.8% since it was found that the lignin component in the corn stalk significantly inhibited the conversion of cellulose to EG. Therefore, delignifying pretreatment must be conducted prior to the reaction. Besides, organic silicon especially tetraethyl orthosilicate (TEOS) could be also obtained from rice straw that contained a large amount of Si. Compared to the industrial production process of TEOS using SiCl4 or Si with multi-steps, where huge amount of HCl was used/produced or harsh conditions were needed, the direct production of TEOS from biomass represented a greener approach and showed greater potential. Fukaya et al.[163] used strong bases and a significant amount of dehydrating agent to promote the reaction of rice hull ash (The main component was SiO2) with ethanol to get TEOS. Sun et al.[164] used the real raw biomass (rice straw) to reacted with ethanol to obtain TEOS successfully. Meanwhile, it was found that reaction temperature influenced reactions remarkably, and the removal of lipids from rice straw facilitated the production of TEOS, giving the highest TEOS yield of 76.2%. In addition, silicon in different biomasses behaved differently in the production of TEOS, which might be related to the complex growth processes of the plants. Until now, there were few works focused on the direct catalytic conversion of biomass (such as rice straw) to TEOS, however, it can be predicted that more satisfied results can be obtained when proper catalysts have been designed and synthesized to promote this process.

In conclusion, at present, many studies that focused on the production of 5-HMF, LA, GVL, FAL, EG, TOES etc. from real biomass, cellulose, hemicellulose, and their derivatives have been reported. Scholars are continuing to explore multifunctional catalysts with high stability and efficiency. Meanwhile, the researches on exploring innovative catalytic systems to achieve high efficiency, safety, energy savings and environmental protection are also the focuses of them.

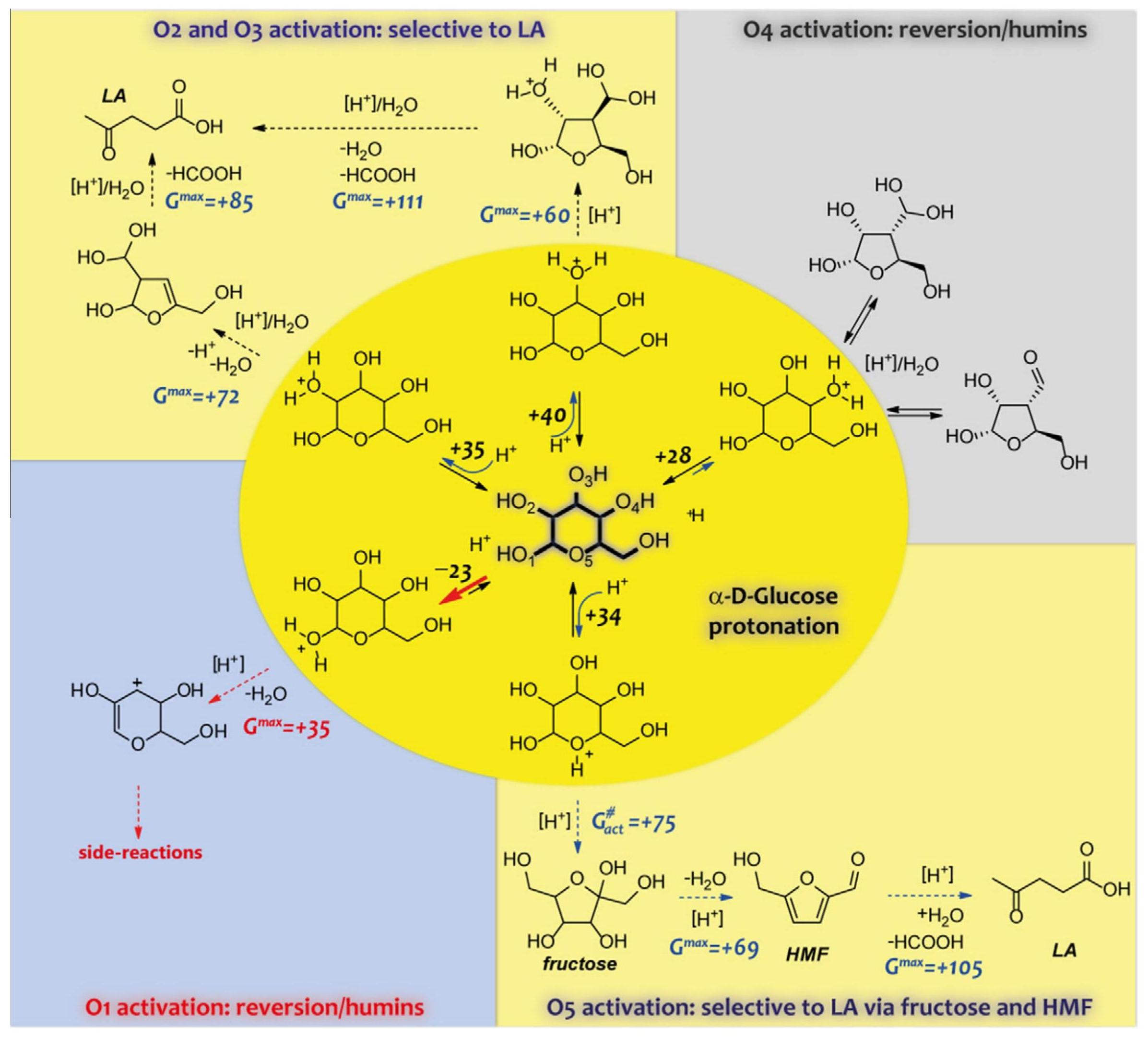

However, we should realize that the conversion of lignocellulose biomass is far more difficult than we imagine now. In fact, much works that focused on the conversion of biomass merely chose one single component such as cellulose or lignin that comes from the real biomass, which cannot represent the real biomass at all. The separation of these single components from real biomass is not simply a physical separation process. On the contrary, much chemical reactions occur, and interactions between different components simultaneously contribute to influence the separation process[165,166]. Meanwhile, the reaction networks for producing these chemicals are rather complicated than we think. Taken the conversion of biomass-derived hexose as example, due to the existence of multiple hydroxy groups in a hexose molecule, the protonation may occur at different positions leading to a variety of dehydrated intermediates, and then various products and side products form. Undoubtedly, these undesired parallel and consecutive side reactions lead to the low selectivity and higher difficulty in precise control. On account of the conformational complexities of the feedstock and the coexistence of multiple dehydration intermediates/products/side products, the reaction types involved in glucose dehydration are also diverse, including isomerization, dehydration, decarbonylation, decarboxylation, rehydration, retro-aldol condensation, and multiple polymerizations etc[167]. The diverse reaction types thereby constitute a complex reaction network, as illustrated in Figure 13[168]. One thing should be noted is that not only reactions can occur between initial substrates, but also between initial substrates and intermediates, intermediates and intermediates, products and intermediates or even products and initial substrates. The high complexity in reaction networks for converting model biomass molecular hexose have already significantly restricted the selective production of targeted products, not to say the conversion of real biomass. Proper or new degradation strategies are still urgently needed to be developed to achieve the full utilization of lignocellulose.

|

Figure 13. The Complex Reaction Network for Glucose-to-HMF Transformation Where G Value Indicates the Reaction Free Energy with a Unit of kJ·mol⁻¹. Reproduced from Ref.[168] with permission from Elsevier.

2.1.2 The Catalytic Conversion of Chitin

At the beginning, the valorization and utilization of shrimp shell or chitin were mainly conducted via bacterial or fungal fermentations and enzymatic degradation. For instance, Serratia marcescens B742 and Lactobacillus plantarum ATCC 8014 were effective in degrading chitin[169]. However, the high cost of enzymes and the low efficiency were some of the pitfalls of this strategy. Catalytic conversion of chitin gradually grabbed the attention of researchers. Under the guide of ‘shell biorefinery’ concept (as shown in Figure 14), distinctive protocols have been established to chemically transform chitin to amino sugars, amino alcohols, furanic amides, and N-heterocycles etc[110,170].

|

Figure 14. The Concept of Shell Biorefinery. Reproduced from Ref.[170] with permission from Wiley.

As for the overall conversion strategies towards chitin, firstly, the chitin polymer was decomposed into monomeric or oligomeric molecules with different functionalities on the side chains through selective depolymerization, deacetylation, and functionalization, whereas the glucosamine C6 backbone was maintained. This strategy was easy to carry out under rather milder conditions, but the obtained products were somehow simple with relatively low added-value. In the other category, the C6 backbone underwent breakage and rearrangement, leading to more diversified products. This method required high temperature to promote the cleavage of chemical bonds and more side reactions would occur accordingly.

The deacetylation of chitin led to the formation of chitosan, and its further depolymerization afforded low-molecular-weight chitosan (LMWC), which were both important compounds since they were featured with excellent antibacterial and antitumor properties. Chen et al.[171] established a one-step, solvent-free mechanochemical method to transform chitin and raw shrimp shell powders to LMWC. The base catalyst, NaOH, was found to not only facilitate chitin transformation into LMWC but also inhibited side reactions under ball milling conditions. Similarly, Yabushita et al.[172] showed that the depolymerization of chitin with a catalytic amount of H2SO4 rather than base could also give soluble short-chain oligomers. Subsequent hydrolysis of the ball-milled sample provided N-acetylglucosamine (NAG) with 53% yield, and methanolysis afforded 1-O-methyl-N-acetylglucosamine in yield of up to 70%. Despite strong base or acid could promote the depolymerization of chitin, effective solvent systems were indeed another ideal option. In 2020, Gözaydın et al.[173] established acidified lithium halide molten salt hydrate (AMSH) systems to convert native chitin into NAG effectively. 71.5% yield of NAG was achieved in LiBr AMSH containing only 40mM HCl at 120℃ after 30min. Likewise, several water-organic co-solvent systems had been studied and established for chitin depolymerization[174]. The effects of cosolvent types on conversion efficiency and product selectivity had been deeply explored. Water-free co-solvent systems, such as EG, FA etc. used for the conversion of chitin had been explored[175,176]. Finer nitrogen-containing chemicals were also obtained by catalytic conversion of chitin. For example, glucosaminic acid (GlcNA), an important amino acid applied in food, asymmetric synthesis, and medicines that could be generated by following a depolymerizaion-deacetylation-oxidation sequence[174]. Dai et al.[177] reported a two-step process by Amberlyst-15 and Au/MgO catalysts to produce GlcNA from chitosan (a typical chitin derivative) with an overall yield of 36%. Hydroxyethyl-2-amino-2-deoxyhexopyranoside (HADP) and hydroxyethyl-2-acetamido-2-deoxyhexopyranoside (HAADP) could be prepared under the catalysis of sulfuric acid in EG[175]. The conversion of NAG that originated from chitin to its corresponding amide/amino substituted sugar alcohols, smaller C2-C4 polyols and N-acetylmonoethanolamine had been reported over Ru/C catalysts in the presence of hydrogen in water[178]. A single compound, 5-(formyloxymethyl) furfural with 35% yield after a longer reaction time from chitin was reported by using formic acid as catalyst[176]. As for the straightforward method mentioned above, the core is to develop efficient solvents and catalysts to break the glycosidic bonds. Especially, developing catalysts with high selectivity is essential. Besides, pretreatments, such as ball milling, are also often involved to facilitate subsequent chemical reactions.

Further treatments of chitin that lead to the breakage and rearrangement of C6 backbone would help to get more diversified products. For example, 3-acetamido-5-acetylfuran (3A5AF), as a kind of versatile pharmaceutical precursor that produced mainly through the Haber process relying on fossil feedstocks[179]. Several works had reported the direct transformation of chitin into 3A5AF with a yield of 7% by using boric acid and alkaline chlorides as catalysts[180], and of 15.4% by using boric acid and HCl as catalysts in ionic liquid [BMIm]Cl[181]. Subsequently, it was further increased to 28.5% using a ball milling pretreatment technique[182]. Later, a range of organonitrogen chemicals derived from the upgrading of 3A5AF, such as 2-acetyl-4-aminofuran, 3-acetamido-5-(1-hydroxylethyl)furan and anticancer alkaloid proximicin had been also obtained, which further promoted the valorization of chitin[183,184]. A report focused on the conversion of chitin and waste shrimp shells into acetic acid and pyrrole by catalytic method using metal oxide (CuO, CeO2) and oxygen gas in basic water was shown. 38.1% and 47.9% yields of acetic acid were produced from chitin and crude shrimp shells, respectively[185]. Natural product syntheses (including Rhizochalinin, Pochonicine, Allosamizoline etc.) using chitin/chitosan represented another promising prospectives for the utilization of chitin[186,187]. Recently, a novel integrated biorefinery method for chitin upgrading had been established, which combined shrimp shell waste catalytic pretreatment and biological fermentation to transform shell waste to tyrosine and L-DOPA (a frontline drug treating Parkinson’s disease). These chemicals were previously unavailable from chitin by traditional chemical processes. This new protocol provides an alternative pathway to synthesize valuable aromatic amino acids from renewable chitin feedstock[188].

In conclusion, different strategies have been attempted to convert chitin to products with distinct structures. An effective dehydration catalyst with high catalytic performance with a proper solvent medium that can weaken the hydrogen bonding network in chitin is critical. However, there is still a long way for us to explore the utilization of chitin since its high complexity. In terms of these already achieved results, deeper explanations on reaction mechanisms when converted chitin to whatever products have not been reported, which is mainly ascribed to the high complexity of chitin. Therefore, advanced or even new convert strategies should be cultivated further.

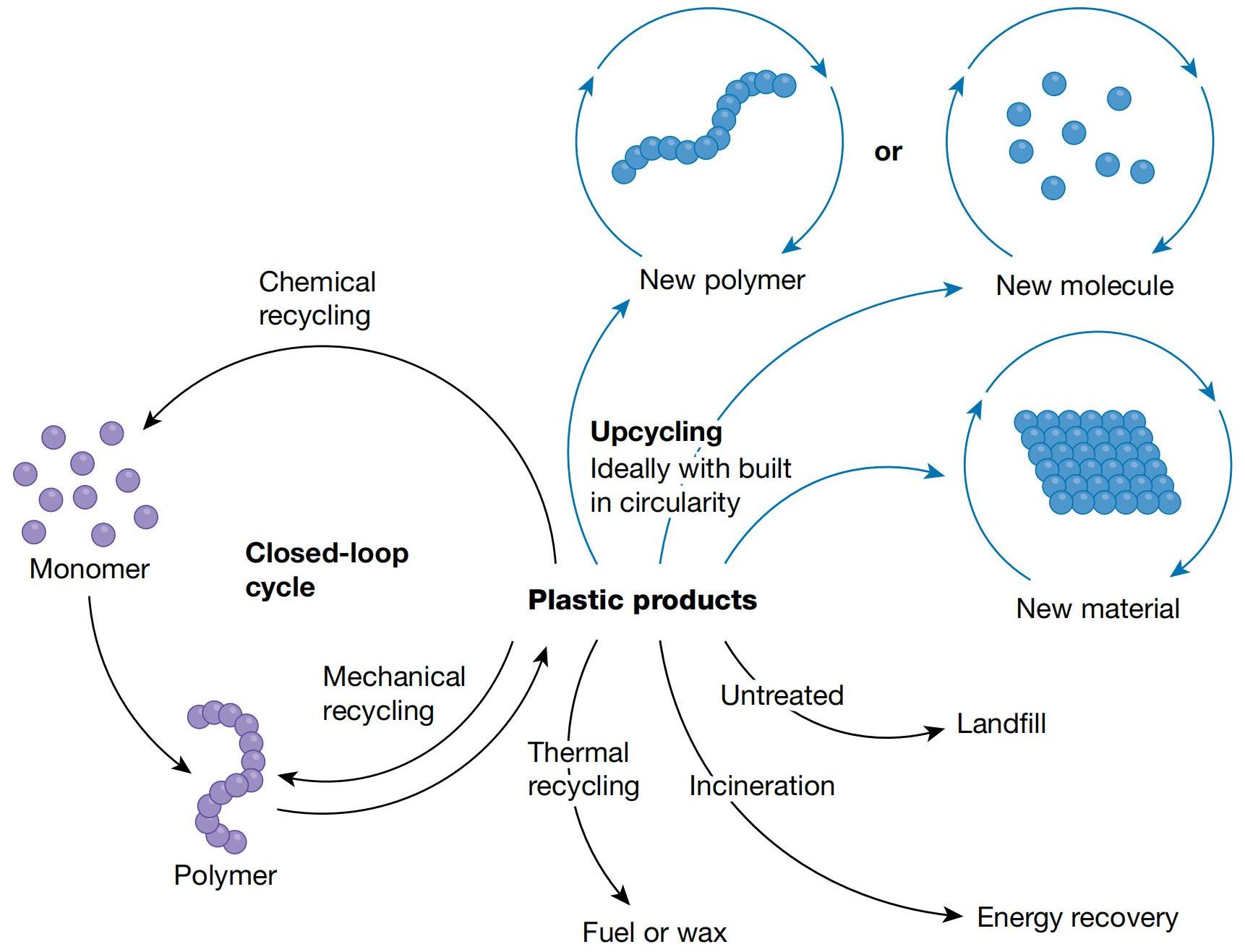

2.2 The Catalytic Conversion of Plastic Wastes

Plastic products are used in almost all aspects of daily life because of their low cost, durability, and portability etc. Besides, the use of plastic products is rising per year. The mass production and the subsequent accumulation of waste-plastic products in Nature have caused serious environmental and management problems[189,190]. Therefore, proper and effective recycling methods should be developed. The diagram for upcycling plastics of its life circle is shown in Figure 15.

|

Figure 15. The Diagram for Upcycling in the Life Cycle of Plastics, Leading to Formation of New Polymers, Molecular or Materials. Reproduced from Ref.[189] with permission from Springer.

However, plastics, as a kind of typical polymer of large- or macro-molecule with highly repetitive subunits (or monomer units) that are linked to each other by specific types of chemical bonds, which brings out much difficulties in upcycling. Fortunately, significant progresses have been achieved. Indeed, there are many excellent reviews summarized the works focused on the conversion of plastic waste via bio-degradation[191-193], photocatalysis[194,195], electrocatalysis[196] and thermal catalysis etc[197,198]. Here, we briefly discussed the potential catalytic degradation strategies. Three strategies have been proposed based on whether a specific intermediate molecule is designed on the route of polymer transformation and the type of the intermediate molecule: (1) polymers are depolymerized to monomers, oligomers, or their derivatives, followed by the upcycling into high-value chemicals; (2) polymers are degraded into small platform molecules (e.g., CO2, CH4, FA, and methanol) and then upcycled into high-value chemicals; and (3) polymers are directly transformed into high-value chemicals[199]. There are advantages as well as disadvantages for each strategy. Usually, high yields of products can be achieved via the first strategy. However, it requires a high purity of substrate, and only polymers that comprised of single monomers can be totally converted, which is difficult to apply for practical use. The second one has advantages for producing various products but with rather lower atom utilization. The third one is beneficial for not requiring pretreatments or multi-conversion steps, leading to the reduced energy consumption and production costs. However, it is more demanding on the catalysts with superior catalytic performances.

López-Fonseca et al.[200] used different types of metal-salt such as zinc acetate, sodium carbonate, sodium bicarbonate, sodium sulphate and potassium sulphate as catalysts to convert polyethylene terephthalate (PET) into monomers. Comparable high yields (≈70%) of the monomer bis(2-hydroxyethyl terephthalate) were obtained with zinc acetate and sodium carbonate as depolymerization catalysts at 196℃. Moreover, other types of catalysts such as organic bases, solid acids, and metal oxides were also employed to degrade PET into monomers[201]. The second step for converting the formed monomers was more meaningful since it provided opportunity to synthesize different value-added chemicals. For instance, under thermo-catalytic conditions, the obtained monomers, dimethyl terephthalate, or bis(hydroxyalkyl) terephthalate from glycolysis in the presence of zinc(II) acetate catalyst, could be further hydrogenated or hydro-deoxygenated to dimethyl cyclohexane-1,4-dicarboxylate, 1,4-cyclohexanedime-thanol by Ni-based[202] and RuPtSn/Al2O3 catalysts[203] respectively, or gasoline and jet fuel range C7-C8 cycloalkanes and aromatics by using Pt/C catalysts[204]. In addition, under photo- or electro-catalytic conditions, the EG units of PET could be oxidized into glyoxal or formate in aqueous alkaline with H2 produced simultaneously over a carbon nitride/nickel phosphide catalyst[205]. Continuing with this guide line, other waste-plastics with ester or amide bonds, such as polyurethane (PU), polystyrene (PS), polycarbonate (PC), and polylactic acid (PLA), could be also upcycled by degrading into monomers.

Extensive progresses over the conversion of building-block molecules (such as CO2, CH4, CO and CH3OH etc.) into fuels and other high value-added chemicals have been obtained, therefore, the degradation of waste-plastic into these small platform molecules is also of great significance to chemical industries. As an example, Jiao et al.[206] accomplished the photodegradation of PE with 100% conversion into CO2 within 40 h by single-unit-cell thick Nb2O5 layers, while the produced CO2 could be further reduced to CH3COOH. This two-step waste-plastic-to-fuel conversion might help to solve the white pollution crisis and harvest highly valuable multi-carbon fuels in natural environments simultaneously. Meanwhile, the same group reported photo-catalyzing plastics to syngas by Co-Ga2O3 nanosheets[207]. In this process, H2O was photo-reduced into H2, while non-recyclable plastics including PE plastic bags, PP plastic boxes and PET plastic bottles were photodegraded into CO2, which was further selectively photo-reduced into CO. CH4 could also be obtained when transforming waste-plastics such as PE, PP and PS, reported by Lee et al[208]. They described that the Ru-modified zeolite exhibited excellent catalytic performance that grid-compatible methane (>97% purity) was obtained at 300-350℃ using near-stoichiometric amounts of H2, which might increase the intelligent use of plastic waste via energy recovery. A nickel-based catalyst involving Ni2Al3 phase enabled the direct transformation of mixed polyolefin plastics into natural gas, and the gas carbon yield reached up to 89.6%, presenting by Fang et al[209].

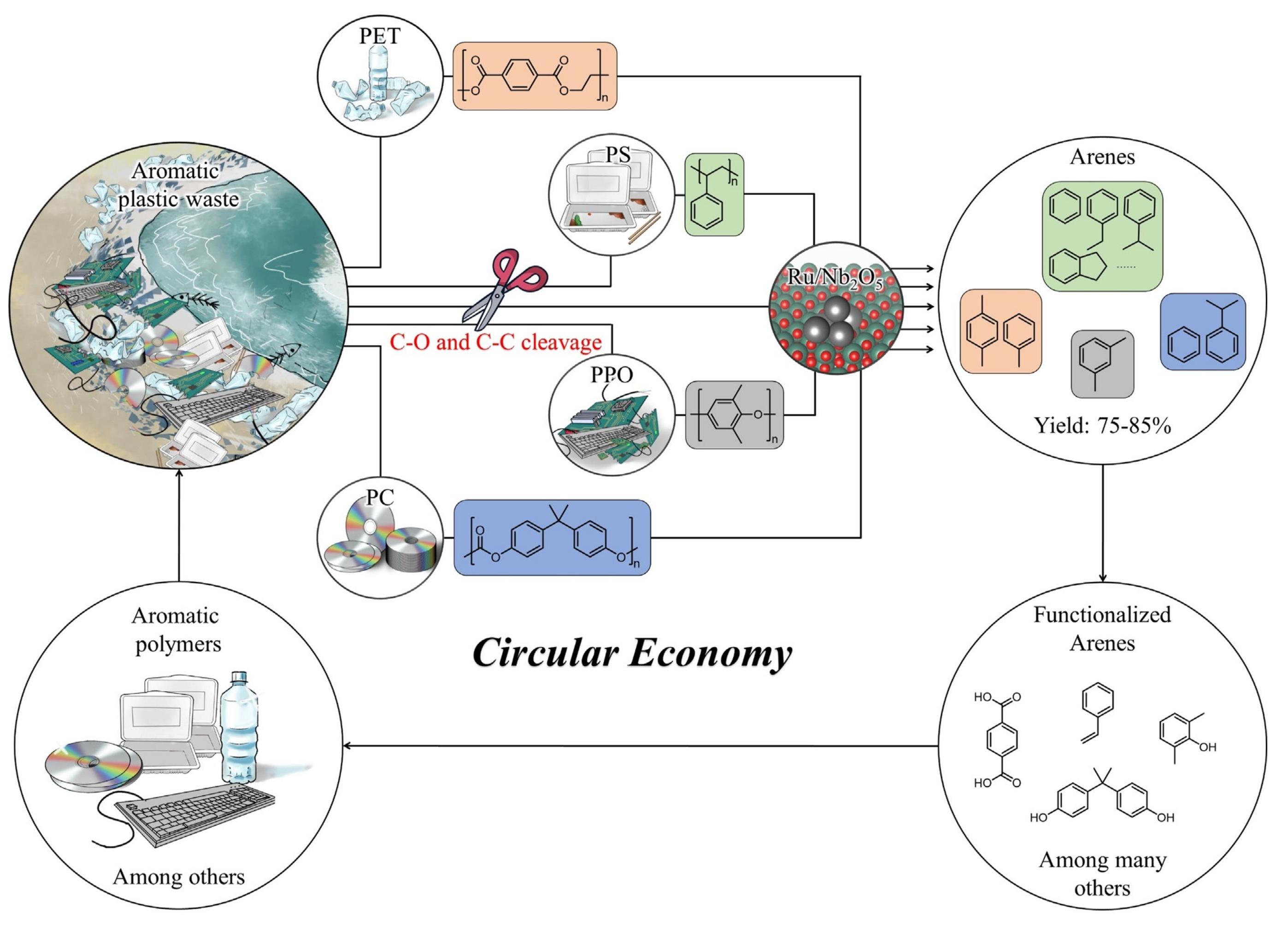

For the third strategy that polymers are directly transformed into high-value chemicals, it is the most difficult yet the most attractive. The core is to design catalytic systems rationally based on precise chemical bonds activation and proper chemical bonds cleavage, which is hopeful to achieve the disassembling of plastics by H2. Direct hydrogenolysis could lead to the cleavage of ester bonds, carbonate bonds, amide bonds, and urethane bonds etc. Lee et al.[208] reported the first example of converting PU to produce diol, diamine, and methanol in the presence of a ruthenium pincer catalyst at 150℃ and 70bar H2. Similarly, PU could be also transformed into diols, diamines, and methanol by using metal or metal oxide complexes under the presence of reducing agents (silanes)[210,211]. In 2020, Wang et al. reported the first example of the upgrading of various aromatic plastic wastes with C-O and/or C-C linkages to arenes (up to 75-85% yields) via catalytic hydrogenolysis over a Ru/Nb2O5 catalyst, which not only allowed the selective conversion of single-component aromatic plastic, and more importantly, enabled the simultaneous conversion of a mixture of aromatic plastic to arenes[212]. The work diagram of Ru/Nb2O5 catalyst to cleavage C-O and C@C bond of waste plastics was displayed in Figure 16, wherein the circular plastic economy could be achieved. Later, deeper work done by them showed a self-supported hydrogenation process of PET with H2-free hydrogenation system to generate benzene, toluene, and xylene (BTX)[213]. Ni2P catalysts were also proved to be effective towards the conversion of PET to BTX fraction[214]. The Co-Fe-Al catalyst containing CoFe alloy with tailored structural features could achieve xylene yields of >99.0% from PET[215]. Recently, Ma and coworkers achieved the one-pot direct amination of polylactic acid (PLA) to alanine catalyzed by Ru/TiO2 in ammonia solution, without the addition of external hydrogen. PLA was depolymerized to lactamide and ammonium lactate, and the following dehydrogenation of ammonium lactate on Ru nanoparticles initiated the amination, leading to the formation of alanine[216]. Besides, by combining a homogeneous catalyst (Hf(OTf)4) and a heterogeneous hydrogenation catalyst (Pd/C), PET were depolymerized into dicarboxylic acid and ethane under 1atm.

|

Figure 16. The Integration of C-O and C-C Bond Cleavage Catalyst (Ru/Nb₂O₅) into the Circular Plastic Economy. Reproduced from Ref.[212] with permission from Wiley.

H2, revealed by Kratish et al[217] . PET could also be completely converted into alkanes, dominated with cyclohexane and methane by Ru/TiO2 under the optimal conditions (200℃, 60bar H2, and small amount of H2O)[198]. Also, a CeO2-supported Ru nanoclusters catalyst showed good hydrogenolysis ability towards low-density PE, leading to the formation of alkane fuels[218]. All of these studies provide possibilities to selective degradation of plastic-wastes, which not only helps to alleviate the environment pollutions, but also contributes to achieve the full utilization of waste plastics.

Except the conversion of waste-plastics that only comprised of mono-components such as PET, PE, PP, PVC, PU, PS, and others, we should pay more attention to the conversion of mixed-plastic wastes since they are closer to the actual human life and recycle situations. For the chemical conversion of mixed-plastic wastes, there are two main strategies that have been proposed[219]: (1) transformation of mixed plastics into a product with a simple composition, and (2) stepwise transformation of the mixed plastics. The first strategy underscores the conversion of mixed polymers into simple products, such as CO, CH4 or H2, or a valuable hydrocarbon, like ethylene or fuels that can be used directly. It follows the same guideline for converting mono-composition plastic as we mentioned before. Once these mixed plastics are depolymerized into smaller molecules, we can further convert them into value-added chemicals through established catalytic methods. It should be noted that real-life plastic waste contains various toxic contaminants, which could potentially inhibit the transformation process. Thus, developing a robust catalyst that can tolerate contaminants is crucial for the success of this strategy. The second strategy involves separating and transforming mixed plastics into valuable chemicals in a step-by-step manner. Firstly, efficient extraction or separation methods allow us to separate these complicated plastics, and later, catalysts with high-catalytic performance allow us to harness the potential of each polymer component of the mixed plastic-wastes. Ultimately, to realize viable catalytic processes to deconstruct and upcycle waste plastics, the actual mechanisms of obtaining intermediates for upcycling via a depolymerization process or direct hydrogenolysis must be clear. Therefore, advanced monitoring and analyzing methods, characterization techniques and even in-situ reactions coupled with detection systems are highly pursued.

Towards the conversion of plastics, difficulties are mainly arisen from the complex chemical bonding in these polymers. However, it is far more complicated for recycling waste plastics since not only chemical bonding is complex, but also different types of polymers with different monomers are usually mixed as well as pollutants that can lead to the deactivation of catalysts. Thereby, more attentions are still needed to pay to achieve the efficient conversion of waste plastics.

2.3 The Catalytic Conversion of Vehicle Exhausted Gases

In recent decades, the environmental protection and long-term sustainability have become the focus of attention due to increasing pollution generated by the sharp increase of vehicles and intense industrialization[220]. It should be noted that there are some differences in the amount of toxic gas emissions released by different types of fuel vehicles, but harmful emissions with high composition complexity including NOx, COx, unburned alkanes, and solid particles etc. could be observed at all situations[221,222]. To overcome environmental issues caused by these vehicle exhausted gases, environmental catalysis has increasingly been used to solve the negative impacts of pollutant emissions on the global environment and human health. However, when the main pollutants in the tail gas COx, HC and NOx contact with catalysts, oxidation and reduction reactions occur on the catalyst at the same time with high complexity, and subsequently being converted into harmless CO2, H2O and N2. Actually, there are more than 400 reactions involved in this process, such as but not limited to these reactions: 2CO+O2→2CO2; CHx+(1+x/4)O2→CO2+x/2H2O; 2CO+2NO→2CO2+N2; CHx+2NO→CO2+x/2H2O+N2; 2H2+2NO→2H2O+N2; CO+H2O→CO2+H2; CHx+2H2O→CO2+(2+x/2)H2. Moreover, the real reaction mechanisms are still being explored. The above commented factors come to be one of the main reasons for its high conversion difficulty. Meanwhile, catalyst poisoning is also annoying, and high production costs and production discontinuity problems arise subsequently. Therefore, exploring robust catalysts with perfect catalytic performance towards the elimination of these exhausted gases simultaneously comes to be the focus in this field.

A worldwide effort to reduce vehicle emissions is advancing, which helps to build a greener, more sustainable Earth for mankind. The development of catalysts used for treating these exhausted gases has gone through three stages. The first generation of catalysts for vehicle exhausted gas purification was oxidation catalysts, with Pt and Pd as the main active components since Pt and Pd had high catalytic activity and stability towards the oxidation reaction of CO and CHx, which had experienced prosperous development between 1975-1980s[223,224]. Later, with the stricter requirements for controlling NOx pollutants, the developed oxidation catalysts could no longer meet the requirements. Accordingly, the second generation of catalysts was three-way catalysts (TWCs) that could deal with CO, CHx and NOx simultaneously. Further modifications on the earlier-developed TWCs that contained noble-metals or non-noble metals became the third generation of catalysts. A detailed description of each type of catalyst will discuss later.

Firstly, Pt and Pd-based catalysts were found to be highly active and stable for the oxidation of CO and CHx, and the reactions occurred according to the following equations:

$$ {C}{O}+1/2{{O}}_{2}\to {C}{{O}}_{2};{C}{{H}}_{{x}}+(1+{x}/4){{O}}_{2}\to {C}{{O}}_{2}+{x}/2{{H}}_{2}{O};$$

Considering the high cost of both Pt and Pd, and to maximize the catalyst performance further, attempts for new catalytic materials that comprised of non-noble metals had been tried, such as base metal oxides including Cr, Ni, Co, Cu and Mn etc. Unfortunately, all of them were unsuccessful at the early stage, which emphasized the essential importance of Pt and Pd[225]. However, decreasing or completely replacing precious metals into alternative cheap metals still continued to be a goal of some recent researches. Another strategy was loading Pt-group metals onto materials with high specific surface areas to increase the number of active sites. γ-Al2O3, CeO2-ZrO2[226,227] were the two main carriers used to disperse these active components (Pt, Pd, and later Rh). Heat treatment thermally fixed or anchored the active components to the carriers, resulting in a Pt-group metal-support catalytic system available for the reactants to chemisorb and convert with high efficiency. Strong interactions between metal and support induced by these operations contributed to anchor metal particles with higher stability, which achieved long-term durability under high temperature operation conditions. For the industrial production, the active components were commonly supported on extruded ceramic monolithic structures (cordierite; 2MgO-5SiO2-2Al2O3), which helped to improve catalytic effectiveness. These kinds of coated monoliths were sufficient with pores for coating a thin layer, and the reactants diffused from the bulk gas to the catalytic wash coat through its porous network in search of the catalytic sites, where they were chemisorbed and converted to products with high efficiency. Due to the recent advanced SACs catalysts preparation methods, applying SACs to eliminate gaseous pollutants had also attracted much attention and came to be another strategy to improve atom utilization efficiency[228,229].

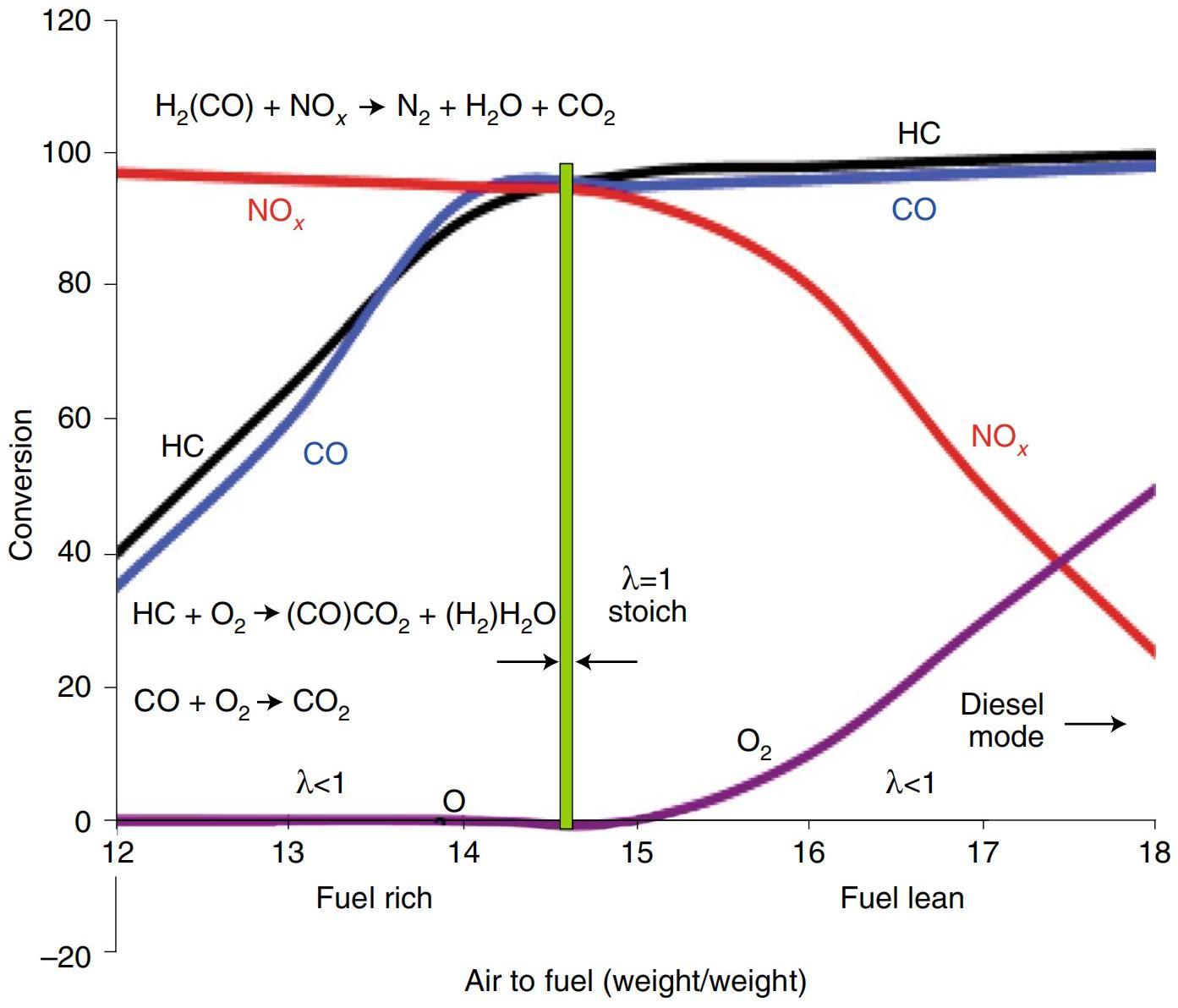

Since 1980, with the increasing need for eliminating NOx from vehicles or industrial emissions, new catalytic systems have been established to convert CO, CHx and NOx simultaneously in concert with engine control and fuel composition change. With the discovery that Rh exhibited good catalytic performance towards NOx conversion[230], the active components of TWCs were mainly comprised of Pd/Rh or Pt/Rh[231-233]. Especially, Pd/Rh catalysts dominated the scene in recent years, aided by the spreading of low-sulfur fuels and cheaper Pd prices compared to Pt. Figure 17 showed the typical performance of a TWC under different air-to-fuel feed ratios, which remarkably influenced the gas composition after burning[232]. The advantages or uniqueness of the TWC was that it could operate primarily at stoichiometric air-to-fuel ratios that were compatible with the oxidation of the three pollutants. It can be seen clearly in Figure 17 that the operation window (in green column) for TWC to convert the pollutants at the same time was narrow. Therefore, an O2 sensor that could convert the partial pressure of O2 in the exhausted gases from the stoichiometric point (λ=1) into an electrical signal were required. Later, the generated voltage sent instructions to the electronic control computer, instructing the fuel supply system to increase or reduce the amount of fuel entering the engine in the feedback control loop. Based on this guideline, taking advantages of the reversible redox and oxygen storage capacities of CeO2-ZrO2 mixture, adding them to TWC help to buffer the disturbance, and ultimately achieved conversion goal. When there was a deficiency of O2 (that is, λ<1), the surface of CeO2 or ZrO2 was reduced while suppling the oxygen to convert CO. The reduced surface of Ce2O3/Zr2O3 was then oxidized back to CeO2/ZrO2 when the perturbation generated excess O2 (λ>1).

|

Figure 17. Typical Performance of a Three-Way Catalyst (Pd and Rh Stabilized on Alumina Plus CeO₂-ZrO₂/Ceramic Monolith) as a Function of Air-to-Fuel Ratio. Reproduced from Ref.[232] with permission from Springer.

Exploring other types of catalysts that can selectively catalyze the reduction (SCR) of NOx into N2, which can reduce or even replace Rh contents, and later couple them with Pt or Pd catalysts to construct TWCs has also obtained much attentions. Liu et al.[234] reported a novel WO3-doped Fe2O3 catalyst that exhibited high NH3-SCR activity in a wide range of operating temperatures and high resistance against H2O and SO2. The highly dispersed WO3 acted as both ‘‘chemical” and ‘‘structural” promoters, which led to the high surface area and more amounts of active sites. Similarly, V2O5-WO3/TiO2 catalysts[235], WO3/CeZrO2 catalysts[236], Fe or Fe2O3-based catalysts[237,238], Co-based catalysts[239,240] etc. had been also proved to be highly effective. More importantly, Cu-based catalysts including Cu/SSZ-13 that had already been commercially used[241,242]. Besides, Cu/SSZ-16[243], Cu/SSZ-39[244], modified Cu-SSZ-13@SiO2 catalysts with a core-shell monolithic structure[245] and coupled CeZrOx-Cu/SSZ-13 catalysts[246] had been also proposed successfully. The above catalysts provided opportunities to achieve the conversion of NOx and vehicle emissions by non-noble metals.

The adjustments or modifications of CeO2/ZrO2 based TWCs was an interesting and attractive strategies for converting these pollutants. On the one hand, modifications focused on the active metals brought out different catalytic performance. For example, alkali and alkaline earth metals were widely used to adjust the electronic structure of supported catalysts[247,248] due to their relatively small electronegativity, which were crucial for binding with active metals through surface oxygen linkages[249]. Constructions of catalysts with ternary or even quaternary metals also shed light on the conversion of vehicle emissions[250]. On the other hand, the modifications on CeO2/ZrO2, such as controlling the morphologies[251,252], crystal phases[253] and exposed lattice planes[254,255] etc. contributed to adjust the redox and oxygen storage properties, and accordingly improved the catalytic performance. Development of new synthetic processes for highly active CeO2-ZrO2 materials or even ternary oxide composites with high oxygen mobility was another vibrant research area[256,257].

In summary, the synthesis of three-way catalysts is the guide line for converting exhausted vehicle gases. At present, efforts have been continuously put to modify these catalysts with high catalytic performance but lower cost.

2.4 The Catalytic Conversion of Pollutants in Water

In the recent decades, the increasing serious water pollution from hazardous and toxic organic pollution agents is annoying worldwide. In the most prevalent examples of waste water, there are inorganic chemicals such as heavy metals, suspended solids, toxic organics and dyes, which are usually emanated from industrial sources[258]. By far, various techniques including chemical precipitation, adsorption, ion-exchange, membrane filtration and chemical catalytic conversion for remediation or purification of waste water samples have been reported. Here, we mainly pay attention to the chemical catalytic methods. As can be predicted, the complex compositions in waste water bring out high conversion difficulty, and multi-functional catalysts that can deal with different types of pollutants are the most ideal target. Indeed, it is difficult to achieve this goal as far as the technology that have been developed. At present, there are no efficient integrated methods that can deal with all types of pollutants in waste water simultaneously. The main strategy for converting waste water is transforming different kinds of pollutants stepwise. The essence for degrading different types of pollutants lies on the cleavage of different chemical bonds, such as COOH, -C-N, C=C, C-O, C-S, and N=N bonds, and halogen atoms. Therefore, the types of required catalysts with high catalytic performance differs, and the degradation paths of materials to different organic pollutants and heavy metals under different conditions are somewhat different.

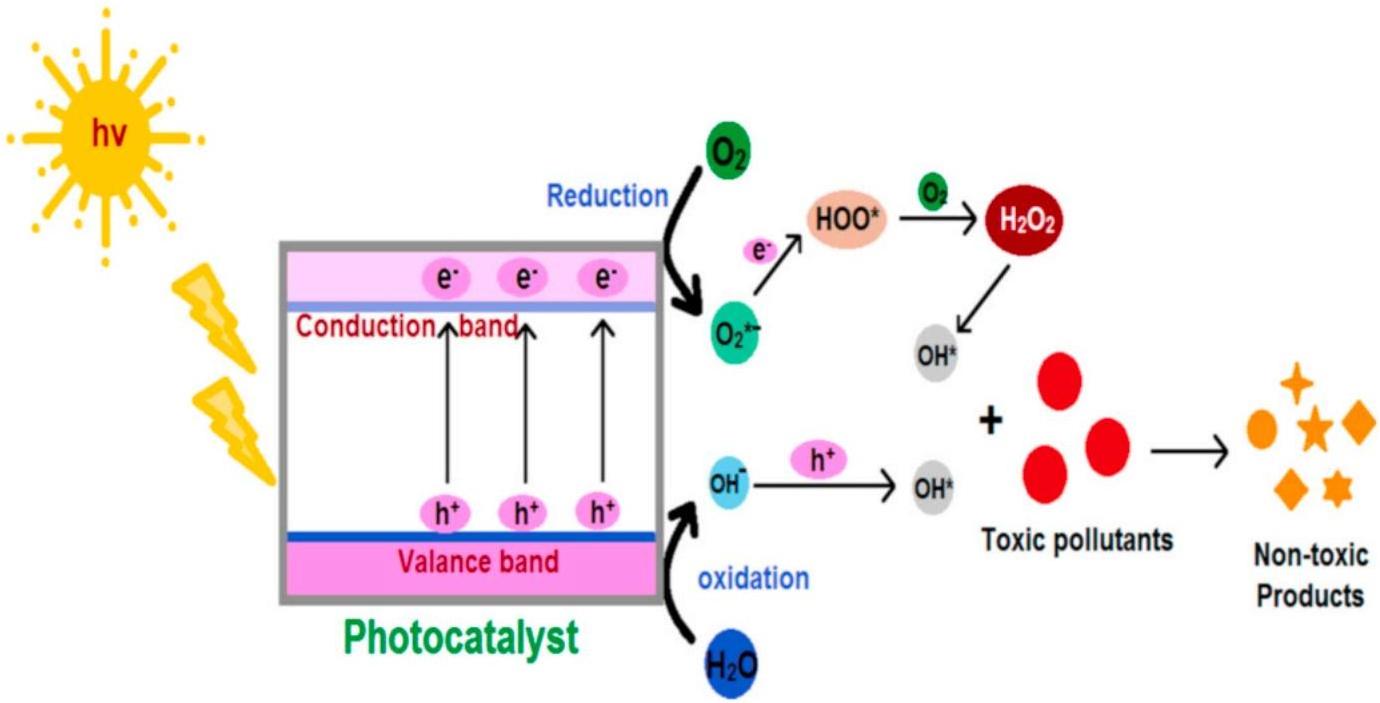

Among the chemical catalytic methods, photocatalytic degradation dominated, which illustrated an effective and promising approach for the elimination and destruction of hazardous contaminants from waste water produced from industries. These photochemical degradation processes called “advanced oxidation processes” could completely degrade organic pollutants into harmless inorganic substances such as CO2 and H2O under moderate conditions. The fundamental mechanism of photocatalysis for the degradation of toxic pollutant was presented in Figure 18[259].

|

Figure 18. Photocatalytic Degradation of Toxic Pollutants. Reproduced from Ref.[259] with permission from Elsevier.